CNC dynamic mould for producing freely curved glass panels

Themes: Social impact, Structural Engineering, Robotics

Late lab scale demonstration

A TRL is a measure to indicate the matureness of a developing technology. When an innovative idea is discovered it is often not directly suitable for application. Usually such novel idea is subjected to further experimentation, testing and prototyping before it can be implemented. The image below shows how to read TRL’s to categorise the innovative ideas.

Why?

As yet, 3DC (=freely double curved) glass panel transforming on moulds CNC milled from steel or ceramic materials, implies great waste in labour, material, energy, logistics and time. Our CNC dynamic mould processing is based on 1 mould that can infinitely be reconfigured.

How?

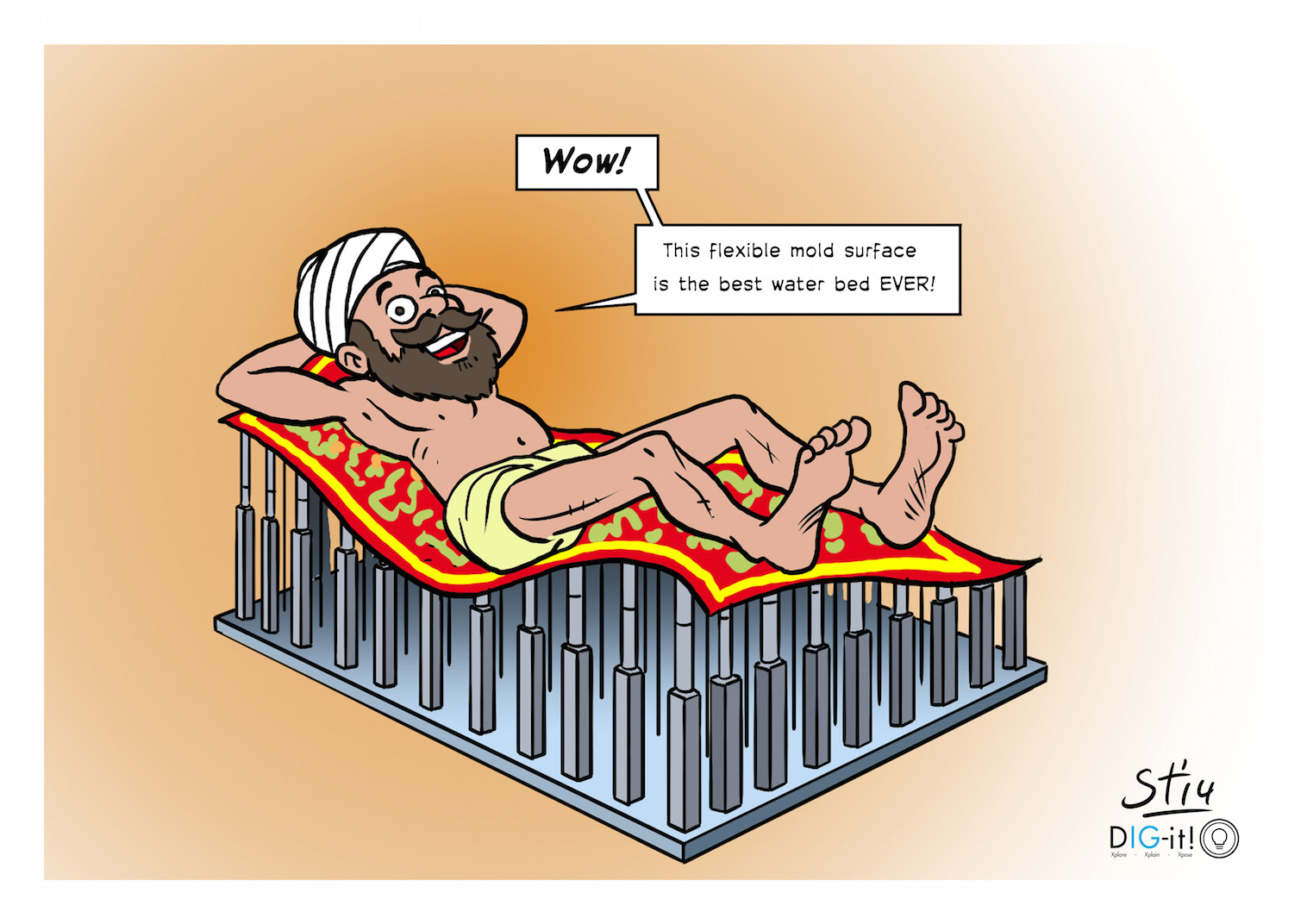

A flat glass panel will be positioned on an array of actuators (pins), which are simultaneously activated to transform the panel in a heating process into the desired 3DC shape. We follow 3 parallel development trajectories: Actuators, CAD-CAM, Transforming Technology.

When?

Dynamic Glass Mould marketing starts in 2016. The market for architectural large freely curved glass panels will become enormous as most buildings need glass. After demonstration as transforming tool for glass, we will apply the technology for processing of other materials.

Dr. Karel Vollers