Halving tomato growers’ energy consumption: LED lighting in greenhouses can make this possible.

The transition from high-pressure sodium bulbs to LED already saves as much as 25% energy. Another smart solution would generate another 35% saving. One way of doing that is by smart positioning of the bulbs, having different light colours and intensity, and by selecting varieties which are well-adapted to energy-efficient lighting. Approximately 60% of electricity in total can be saved on lighting. By making use of LED, savings can also be made on controlling humidity. Because LEDs give off less heat, the heating will have to be turned up a little, but it would be realistic to aim for net savings on electricity of 50%.

Separating light and heat

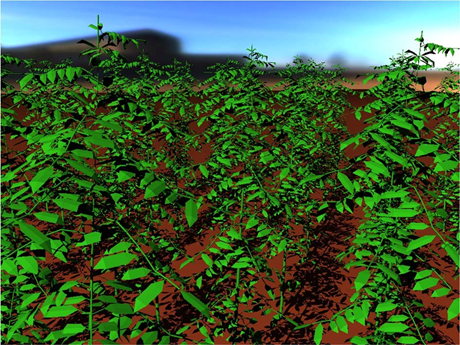

The fact that LED bulbs become less warm is also an advantage. Apart from being positioned above tomato plants, they can also be put in between. Shining light on plants from the side as well will generate considerable profits. Research is needed to investigate which colour of light would be best to use during different stages. That is because it is important to the grower for the plant to perform the optimal photosynthesis to make fruit – and not just extra leaves. Some varieties do this more than others. Having this knowledge is not just interesting for growers, but also for plant breeders.

Lighter and drier

LED lighting also changes the water balance in greenhouses. Light colours affect whether plants’ stomata open or close. That can increase the plants’ resistance to disease. When it is sunny, growers want plants to keep their stomata open for longer to absorb CO2, which is then converted into plant growth. However, open stomata mean more evaporation, more humidity in the greenhouse and a greater risk of fungal diseases. On cold, dark days and at night – if the heating has to be turned up to maintain the temperature in the greenhouse – energy can be saved by having the stomata close a little more. A lot of energy in the form of heating is used to control humidity at such times. Energy can be saved by lowering evaporation.

Investigations are also being carried out to discover whether plants lit by LED light are also more resistant to fungal diseases such as mildew and botrytis. If so, growers could easily accept higher humidity in their greenhouses, which would also save energy.

All the business processes, from the use of coloured light in various phases through to managing the water balance, will be included in a decision model for growers, which is also being developed in this project.

TU Delft

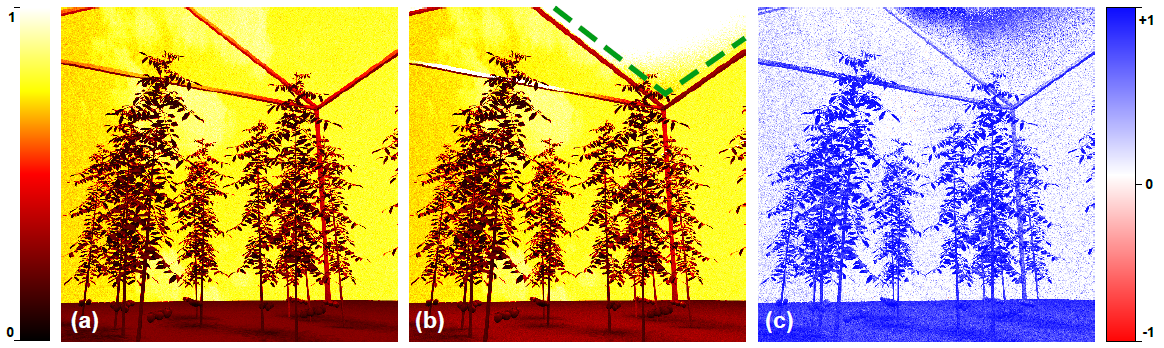

Research is also being carried out into where the bulbs should be positioned. That is a difficult issue as it involves many different parameters. We started with empirical research: bulbs were placed high up, low down and along the sides of the greenhouse. We then examined which configuration produced the best crop. TU Delft supported this research with computer models, as it would otherwise have taken 7 months before we had a result. Computer modelling can predict the spread of light fairly accurately. Reflection in the greenhouse, emissions and the wavelength of the light were included in the model. Eventually this model will be combined with another model being used by colleagues in Wageningen who are working on the same sub-project. It will predict how much a plant will grow depending on the amount of light that falls onto the leaves.

The TU Delft software is suitable for application in a wide variety of settings and could also be used to predict light distribution in buildings.