The ground beneath our feet is an excellent place to store renewable energy. But before we do, the implications of using underground reservoirs have to be thoroughly researched. If the gas extraction-related earthquakes in Groningen have taught us anything, it is that they must be prevented at all costs. Applied Geophysics & Petrophysics PhD candidates Milad Naderloo and Aukje Veltmeijer are investigating if earthquakes caused by human intervention can be predicted and prevented.

A huge metal door that looks as if it might have fallen off a safe is sitting on a trolley in the lab. The two researchers are using it for their tests. “It’s really heavy, 900 kilos, we weighed it,” Milad Naderloo laughs.

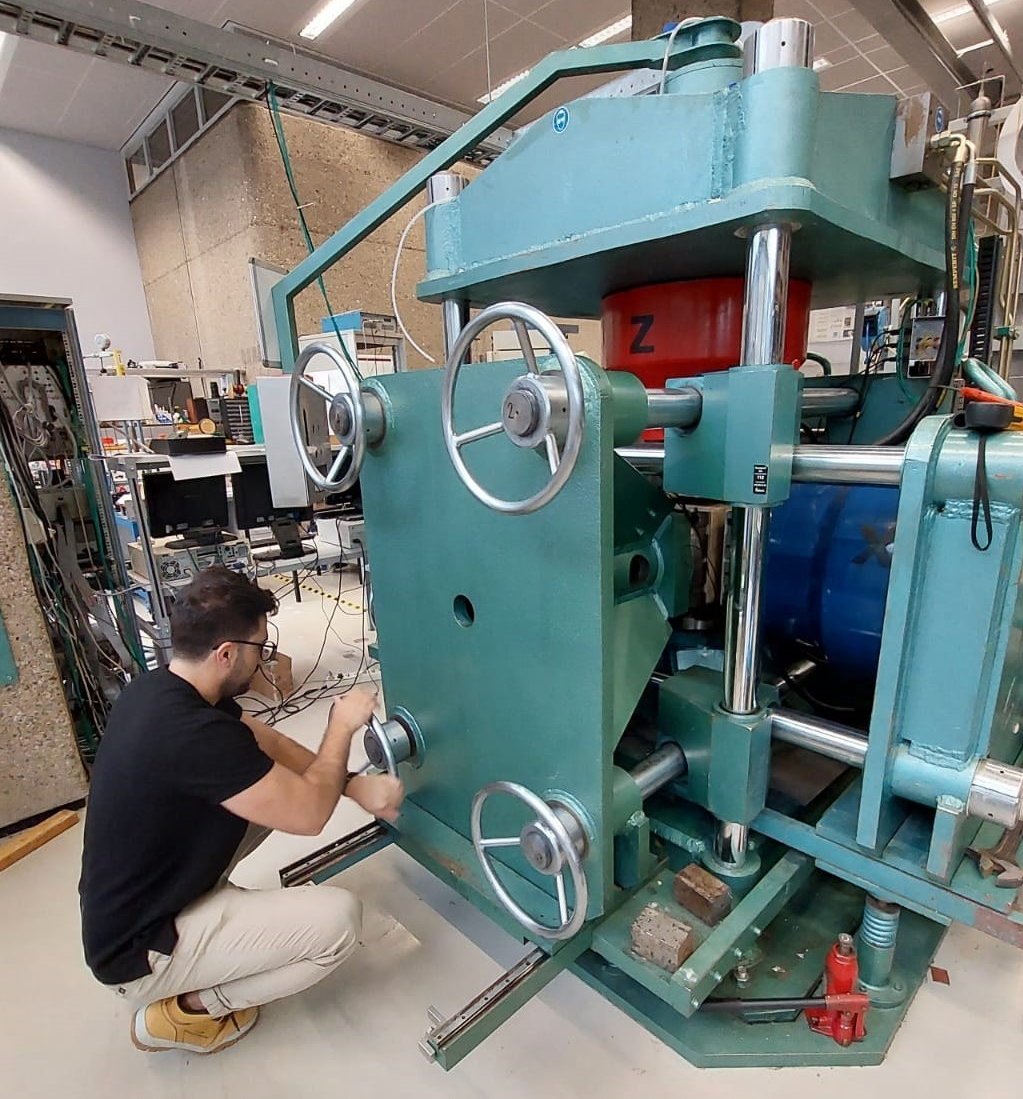

It is, in fact, part of a powerful machine Naderloo and fellow PhD candidate Veltmeijer are using to simulate the enormous pressure that exists at a depth of 2,500 meters below ground. “Not a lot of people are lucky enough to have this fancy piece of machinery to work with,” Naderloo says. The depth is interesting from a geological point of view because it is where underground reservoirs are located, like the gas field in Groningen. But underground reservoirs can also be used to store sustainable energy.

One example is hydrogen. The gas plays an important role in the energy transition, since it is a way of storing renewable energy. Storing hydrogen in underground reservoirs offers opportunities: it is cheap, there is plenty of space beneath the surface and it is usable for long term.

Simulating an underground reservoir

Safety is the overriding concern. “The last thing we want is causing earthquakes, as happened after gas extraction in Groningen,” Naderloo says. Their fundamental research into the causes of induced earthquakes must pave the way to the safe use subsurface reservoirs.

Their research also includes ways of preventing earthquakes. Veltmeijer: “I hope to be able to predict where an earthquake is going to take place.” Based on that information a warning system can be made which can then prompt action to tackle it. Naderloo: “I want to find a way to control the earthquake and turn a powerful quake into perhaps ten that are so small they won’t even be felt.” But how to duplicate the conditions of an underground reservoir in a lab?

Harley Quinn Samples

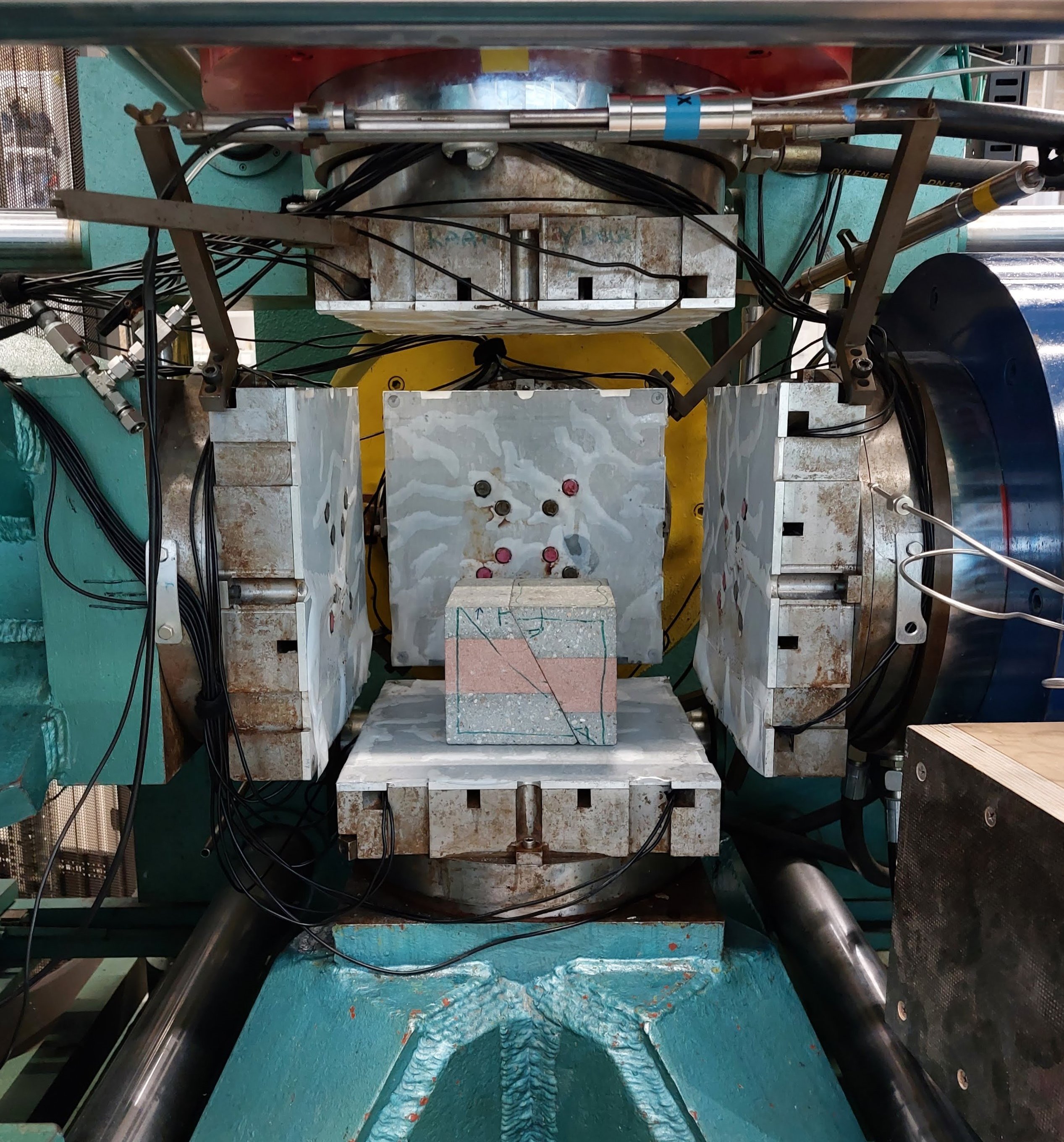

The giant machine in the lab is surrounded by pieces of rock, some greyish brown, others red. Many of the research samples show a variety of coloured layers. “We call them Harley Quinn samples as a similarity,” Naderloo says. Most of the samples consist of two pieces cut at an angle placed on top of each other.

Each of the samples represents a “mini reservoir”. An underground reservoir consists of porous sandstone which you can compare to as a sponge. The small pores may contain water or gas. “If those tiny spaces are emptied, the pressure on them is smaller. Weight of the earth layers on top compresses the reservoir,” Veltmeijer explains.

The risks of built-up pressure are greatest around natural fault lines, the place where two fault counterparts meet. In the samples, these show as the oblique saw cuts. If these blocks compress, the rock layers will start to shift which causes an earthquake.

Veltmeijer and Naderloo are investigating the exact relationship between block subsidence and the occurrence of earthquakes. Based on modelling, other scientists - also involved in DeepNL - came up with the theory that earthquakes start where one type of rock meets another, along the fault line. Naderloo and Veltmeijer are now putting this theory to the test in the Geoscience & Engineering lab. After many experiments on small pieces of sandstone, that gave a basic understanding of forecasting and preventing earthquakes, is was time to construct the mastersample. It eventually took them a good two years to put together the right testing facility.

Attempt number one

The biggest challenge they faced was to find a way to put pressure on the rocks from the inside. The idea was to pump water into the rock, hoping the reservoir wouldn’t spring a leak. Their first attempt consisted of putting a concrete layer around the sandstone. To check if the sandstone was watertight, they proceeded to pump blue ink in and out of the sample. The concrete soon gave way under the pressure, causing a fountain of ink. “It was a sad moment but it looked pretty spectacular,” Naderloo says.

Reinforcing the concrete was not an option, Veltmeijer said. “The iron wiring would interfere with the acoustic signal given off by the sound sensors that pick up signals of an earthquake or slide occurring inside the sample.” Lab technician Marc Friebel came up with an alternative. He fitted the concrete coating with a rubber edging which, Veltmeijer says, “worked remarkably well”. “Unfortunately, the rubber affects the way the rocks interact on the fault line,” Naderloo says. So it was back to the drawing table.

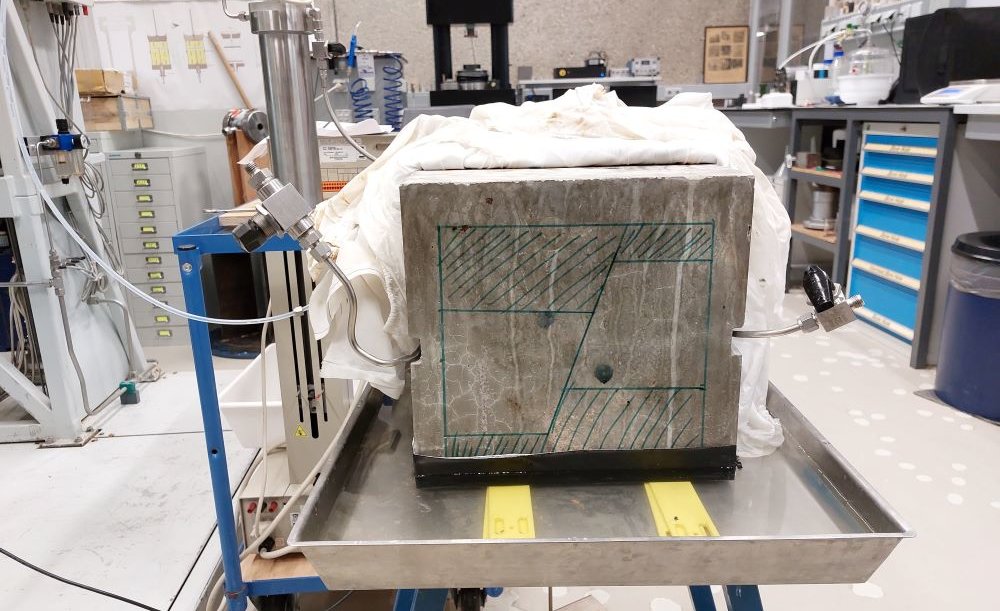

Master sample

The solution turned out to be an aluminium glue cover. The advantage of aluminium is that it doesn’t muffle sound signals and doesn’t tear under pressure. “We were so happy when we finally managed to seal the block,” Naderloo says. The sandstone was covered in a layer of concrete, an aluminium cover and another layer of concrete until it measured exactly 30 x 30 cm, making it an exact fit for the pressure machine. Every concrete layer took over a month to harden, a time-consuming process, particularly after cracks saw off the first attempt. A later attempt was successful, however, and the master sample was finally ready to put the modellers' theory to the test.

From a technical point of view I couldn’t be happier. We now have a testing facility that works and that opens the door to lots of other experiments.

Upping the pressure

“It was a tense moment,” Naderloo said, describing how the sample was put into the machine as Friebel winched the huge metal door into place. As the pressure was gradually increased, the sample reached a simulated depth of three kilometres. Water was pumped into the sample under high pressure and released in one go. Meanwhile, twenty sound sensors were poised to pick up signals of a slide – or even a small earthquake. It then took four weeks to process the sound sensor data, stored on a stack of hard disks.

The result of this first test showed no slide or earthquake had taken place, and the question of whether earthquakes happen in the predicted spot has to remain unanswered for now. The researchers continue undeterred and will tweak the procedure to provoke a movement in the blocks. Naderloo: “From a technical point of view I couldn’t be happier. We now have a testing facility that works and that opens the door to lots of other experiments.”

Meanwhile, the master sample is being carefully watched to preserve for the upcoming experiments. “It needs more water,” Veltmeijer tells Naderloo as she checks the damp cloths in which it is wrapped to prevent cracking. “Being held up once by cracked concrete was enough,” they both agree.

DeepNL

Naderloo and Veltmeijer’s project is part of DeepNL, a research programme that was started in the wake of the earthquakes in Groningen. The programme comprises some twenty projects at universities across the country and is aimed at gathering data about induced seismicity.

![[Translate to English:] [Translate to English:]](https://filelist.tudelft.nl/CiTG/Onderzoek/Stories%20of%20Science/Geoscience%20%26%20Engineering/Een%20aardwarmtebron%20voor%20onderzoek%20op%20de%20campus/phil-on-mount-4.gif)