Hydrogen in a solid carrier

The hydrogen carrier sodium boron hydride can be made to release twice as much hydrogen. This discovery by start-up H2Fuel could make hydrogen storage more practical. Klaas Visser (3mE) sees applications for the maritime industry.

Sodium boron hydride (NaBH4) is a white powder that was previously used in detergents. In contact with water and with the help of a catalyst it releases hydrogen. Up until 2007, this generated no more than 30% of the bound hydrogen, but then Gerard Lugtigheid, a researcher at H2Fuel, discovered that purer water generates more has also been in operation for two years and has a capacity of 125 kW. Sodium boron hydride is currently purchased for this process. “This is too expensive for maritime applications.” says Visser. “We really need to regenerate it ourselves.” Visser won’t yet say what specific chemical processes are involved in this regeneration. “The technique is proven on hydrogen. The powder does not only release hydrogen, but also the hydrogen atoms from the water molecule according to the equation: NaBH4 (aq) + 2 H2O (l) → NaBO2 (aq) + 4 H2 (g). In other words, the hydrogen is doubled. This technical concept has been patented by H2Fuel. Klaas Visser, associate professor of maritime engineering (3mE), became interested in H2Fuel’s technology around 2016. “The energy density of the powder (27 MJ/litre) is relatively high compared to other forms of hydrogen storage, and is close to diesel fuel (36 MJ/litre),” he explains. “Furthermore, with a flashpoint of 70°C, the powder is safer to transport and bunker than hydrogen in gaseous form.”

This means that sodium boron hydride meets three important conditions for zero-emission ships. “Not unimportantly, the water needed for the reaction with sodium boron oxide is available on a ship,” adds Visser, “and with reverse osmosis and filters this can be purified to make ultra- pure water.”

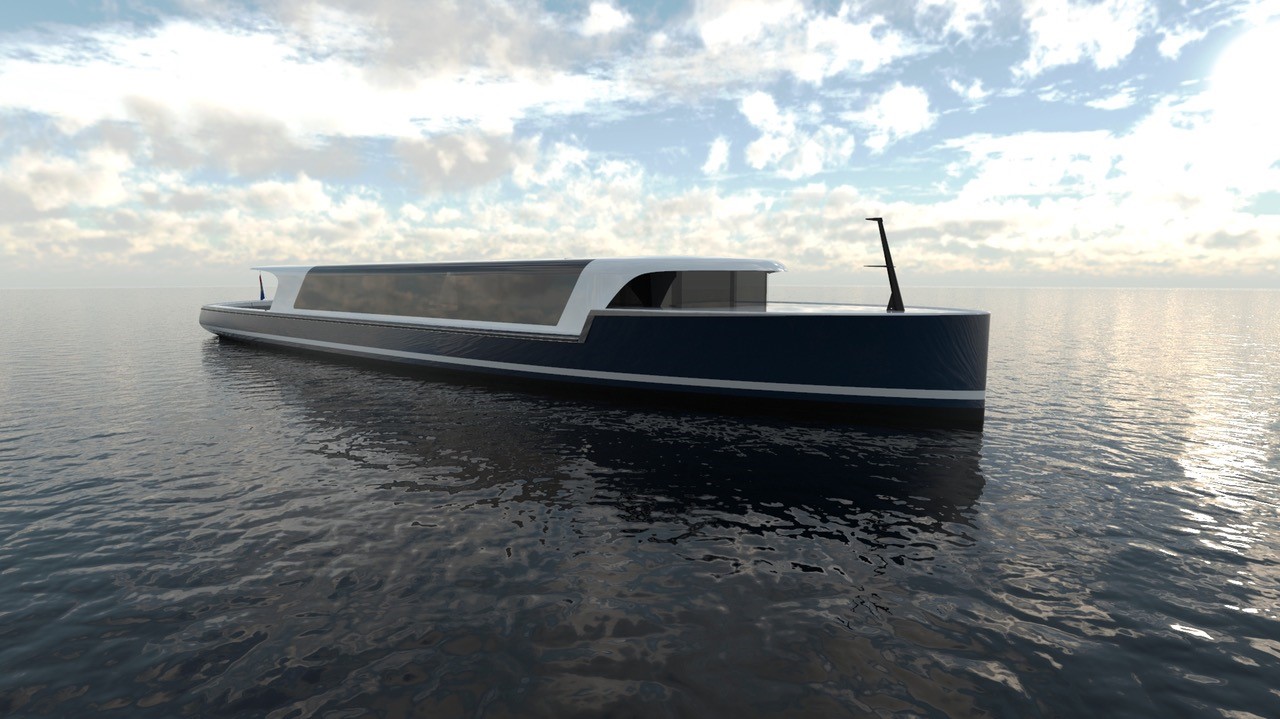

An important topic for research is how to make the process circular. Not only does the ship’s tank become much heavier during the voyage due to the formation of the residual product sodium boron oxide (NaBO2), it is also a challenge to regenerate the original sodium boron oxide using green energy and without producing waste. Visser: “The process is not yet circular, but TU Delft and the University of Amsterdam are working hard on this.” These universities are designing a pilot reactor for regeneration. In 2021, the Port of Amsterdam will start the construction of a ship that will sail on sodium boron hydride in a pilot of the Interreg H2SHIPS project.

“We learned how to separate the hydrogen from the carrier two years ago,” says Frank Dobbelaar, co- director of H2Fuel. The pilot plant in Rotterdam paper and we are already using it, but it can be made even more efficient,” explains Dobbelaar.

A consortium of companies called Solid Hydro.Re.Gen is cooperating to develop sodium boron hydride as a hydrogen carrier. In addition to a number of maritime partners, railway infrastructure company ProRail also participates.

Once all the techniques have been proven and have also been demonstrated to be economically viable, sodium boron hydride could be used on inland vessels, short-sea vessels, maintenance vessels and ferries, for example. “We expect to be able to start within the next five years,” says Visser.