Marieke Klijn detects changes in biotechnological processes in real-time, with the use of new monitoring techniques. She wants to move biotechnological research away from old-fashioned manual sampling to much more efficient continuous testing: “We can now know at once how many cells are alive during the production process, or how fast they are eating glucose, for example – all without the need to take a sample.”

“My research focusses on ways to optimize production processes for biotech companies, by developing methods for continuous testing,” Marieke Klijn, assistant professor at the biotechnology department of the TU Delft, begins. “My team aims to make measurements an automatic part of production processes in biotechnology. I want to integrate sampling directly into the process – real-time testing: that way, we no longer need to rely on time-consuming manual handling in order to know how well the production process is going.” She set up her lab at TU Delft in September 2020.

Higher quality and more sustainable

Klijn explains that continuous testing will lead to biotechnological products with higher quality and processing efficiency: “Real-time testing improves product quality, because the biotech company has continuous control of the product: the computer can easily detect deviations in the production chain at a much faster pace and change parameters so as to prevent failure, like a loss of product or unhappy cells. Real-time testing is also required if you want to move to continuous manufacturing, which allows companies to reduce their footprint and become more sustainable.”

The biopharmaceutical industry is actively searching for more continuous processing setups that can lead to more efficient and affordable production of medicine, such as vaccines or cancer medicine. Klijn: “A continuous process flow already exists in other types of industries, such as the petrol industry. But in the case of biological matter, continuous processing and testing is more difficult: it has more technological, biological and regulatory challenges. You can’t be sure of the result in advance.”

Eating habits of cells in real-time

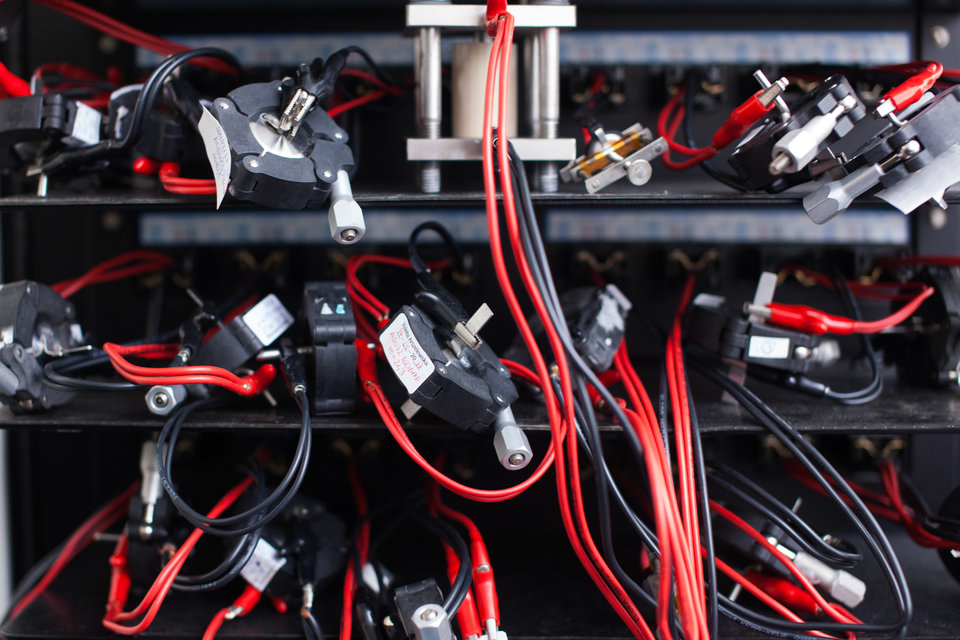

“In my lab we have a setup to insert analytical techniques into a bioreactor and extract processing data in real-time,” Klijn explains. “A bioreactor is basically a vessel with nutrients and cells. These cells can produce a specific biotechnological product, for example a food additive or a drug compound, in a highly controlled environment. We would like to monitor different cells to find out how to make these models robust for industrial application: so that when products or cell lines change, the company doesn’t need to go through the whole development phase again.”

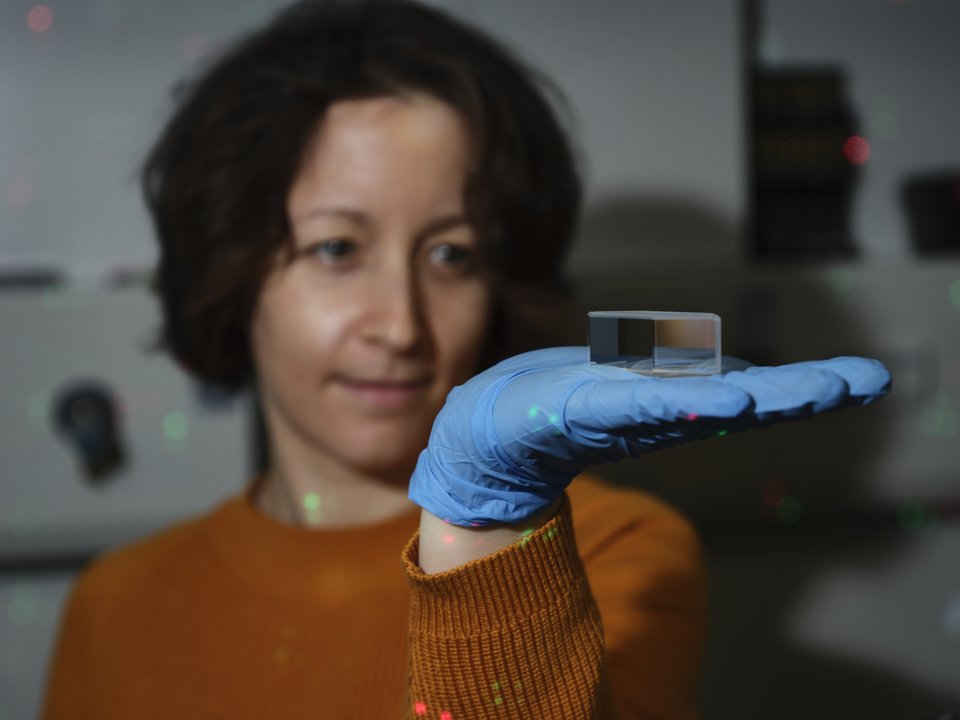

The main analytical tool that Klijn’s lab uses is Raman spectroscopy: a technique in which laser light is scattered due to molecular vibrations. Each molecule will have a different scattering pattern, making it possible to study all kinds of changes in different molecules in real-time: “With this technique we now know at once how many cells are alive during the production process, or how fast they are eating glucose, for example – all without the need to take a sample. The combination of this analytical technique and machine learning makes it possible to look at many different parameters at the same time.”

Blurry lines

The biotechnological industry already makes use of Raman spectroscopy: they show a lot of interest in the models that the team can build for the process control systems. “We would like to capture as much information as feasible. For example, in addition to Raman spectroscopy, we want to use real-time imaging data to tell us how the cells are changing during the process of glucose eating.” The sheer amount of data this entails presents a challenge in itself, Klijn says: “Our dilemma here is how to effectively use the huge amount of information that we acquire.”

How has this new focus on improvements during bio-production influenced the research field? “Before I started this work, each specialist would focus on their own part of the manufacturing process. Now the lines are blurry and they all work together. This makes the work very diverse. I can combine implementation of data analytical tools, with how the cell works and bioprocess engineering solutions. I work with experts from many different fields on the upstream part of processing, such as cell cultivation, and the downstream part such as modellers: all to make the production process into one single continuous flow.”

Dr. ir. Marieke Klijn

Assistant Professor

- +31 15 27 81280

- m.e.klijn@tudelft.nl

-

Room C0.550

Building 58

Van der Maasweg 9

2629 HZ Delft