This week, NWO announced that the RELEASE project, lead by prof. dr. ir. Paulien Herder, will recieve funding within the Crossover-programme. The aim of RELEASE is to store sustainable energy, in order to make it available when it is needed. To do that, the consortium will use a multidisciplinary approach which extends from research in the lab to implementation in the field.

Strong ambitions

The objectives of the international climate agreement in Paris or that of her Dutch sister, the recently presented ‘klimaatakkoord’, are ambitious to say the least. Compared to the 1990 level, greenhouse gas emissions must be reduced by 49% in 2030 and by as much as 95% in 2050. This has significant consequences for our chemical industry. Due to the scale and complexity of the challenge, we have to look far ahead. The chemical processes that this industry is currently using on a large scale will have to change fundamentally; higher efficiencies, more reuse, alternative raw materials, and alternative sources of energy are all necessary.

Electrification

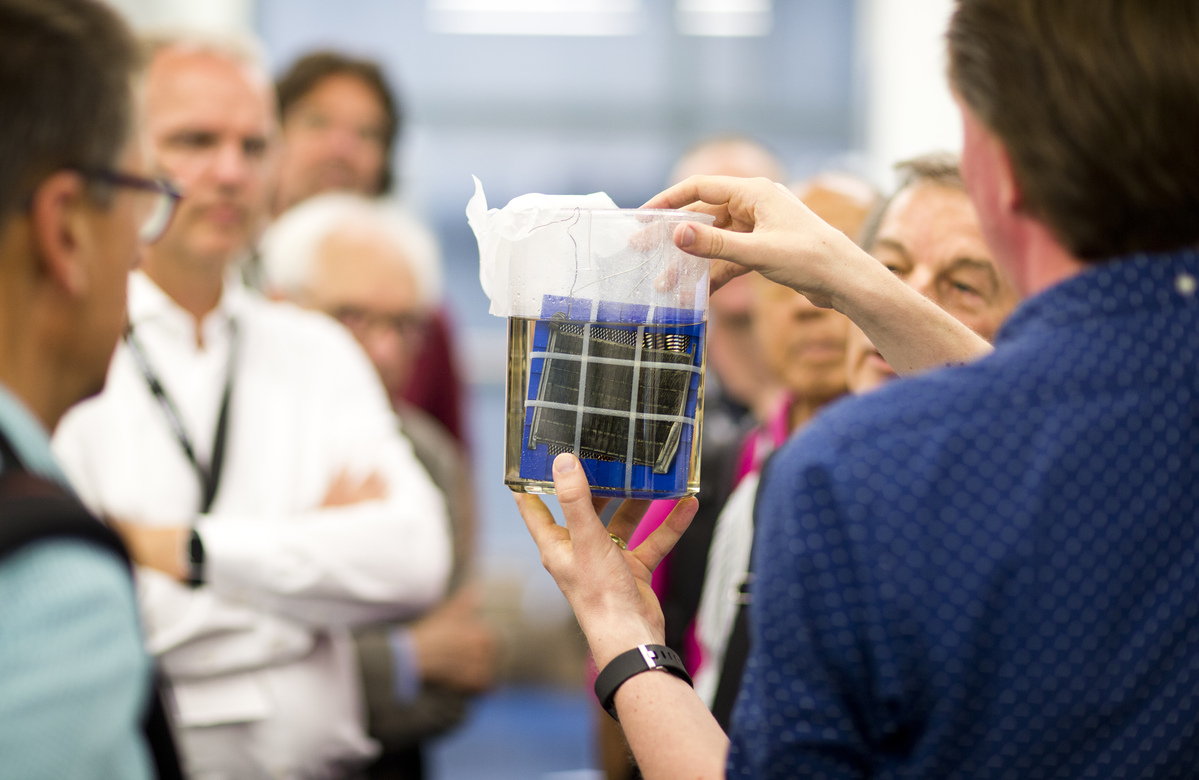

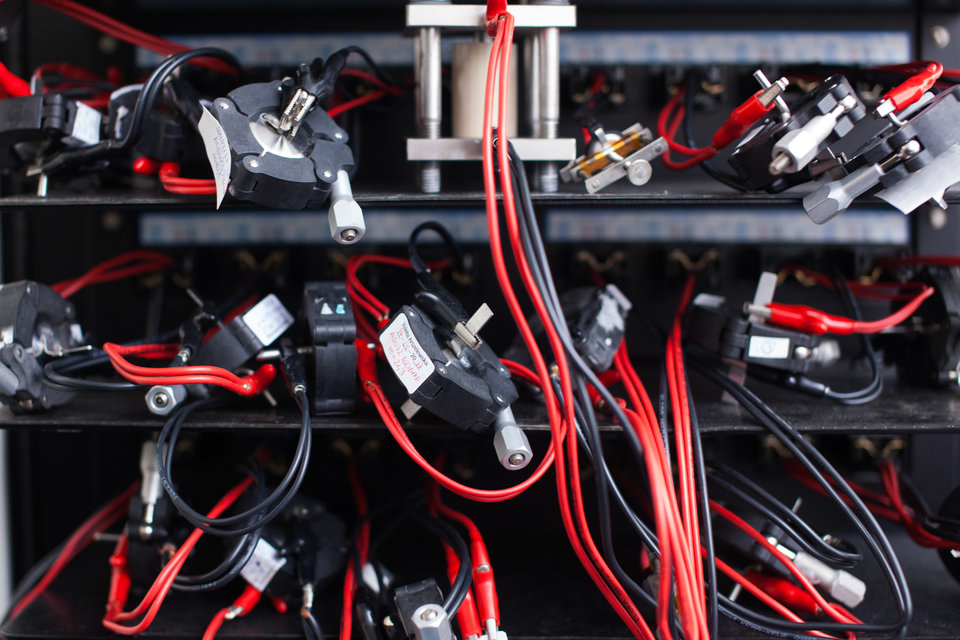

All options to achieve these ambitions are currently being considered, but it is clear that the electrification of chemical production processes will be an indispensable component in the future. The field of electrochemistry revolves around the use of chemical compounds for the large-scale storage of energy and, conversely, the large-scale production of organic chemicals using electricity, instead of by burning fossil fuels. For example, with the help of electricity, water and CO2 from the air can be converted into syngas and the raw materials for the production of fuels or plastics. This process is called electrolysis. Scientists are studying and improving such chemical processes, with a major effort being placed on finding catalysts that accelerate electrolysis and make it cost effective.

Huge scale

This work mainly takes place on a laboratory scale. So, there is still a long way to go. Anyone visiting one of the Dutch chemical clusters, for example in the Eemshaven or the Botlek area, will quickly realize that the enormous scale of production by the chemical industry makes a rapid and painless transition impossible. There are high costs involved. And if that transition is to be completed in 2050, then the chemical plants of the future must be built from 2040 or even 2030 onwards. This leaves little time to develop, test and scale up new chemical processes.

If we do not start testing on a relevant, large scale in time, we may develop electrolysis routes that cannot be scaled up at all. If we want to find the desired catalysts on time, we have to think ahead.

Dr. Thomas Burdyny

Common approach

The Delft e-Refinery initiative was created last year to point the way for that approach. Within e-Refinery, around forty scientists from the Faculties of Technology, Policy and Management (TPM), Mechanical Engineering (ME), Applied Sciences (TNW) and Electrical Engineering, Mathematics and Computer Science (EWI) work together to enable multidisciplinary and multi-scale research. In recent weeks, scientists from this e-Refinery have come up with new results. Furthermore the scientists cannot take these steps without governments, business and academic disciplines.

Future catalysts

For example, in the journal Energy & Environmental Science, mechanical engineer Dr Thomas Burdyny and chemical engineer Dr Wilson Smith provide advice on testing future catalysts. Burdyny: “The development of new catalysts is essential for our search for a form of electrolysis that is efficient on a large scale. Only with the right catalyst can we remove CO2 from the atmosphere and pump it into our economy. Our research now shows that the scale on which the chemical process is implemented (in technical terms: the current density) influences catalytic parameters that determine the efficiency of the process as a whole. In other words, if we do not start testing on a relevant, large scale in time, we may develop electrolysis routes that cannot be scaled up at all. If we want to find the desired catalysts on time, we have to think ahead.”

Negative emission

Recent results from energy scientist Prof. Andrea Ramirez Ramirez (also published in the journal Energy & Environmental Science) try to steer future developments in the right direction. She reviews the divergent definitions of so-called ‘negative emission technologies’ and proposes a uniform definition.

Ramirez Ramirez: “There is a lot of attention for techniques that use more greenhouse gases than they emit, and therefore have a ‘negative emission’. But because of different definitions, we run the risk of wasting time on techniques that actually cause a net increase in greenhouse gases. We propose four criteria for reliably labelling technologies as negative emissions technologies. In short, there must be capture and permanent storage of greenhouse gasses, with the inevitable emissions to achieve this being known in detail and less than the amount of captured greenhouse gas.”

There is a lot of attention for techniques that use more greenhouse gases than they emit. But because of large differences in carbon footprint assessments, we run the risk of wasting time on technologies that could actually cause a net increase in greenhouse gases

Andrea Ramirez Ramirez

e-Refinery

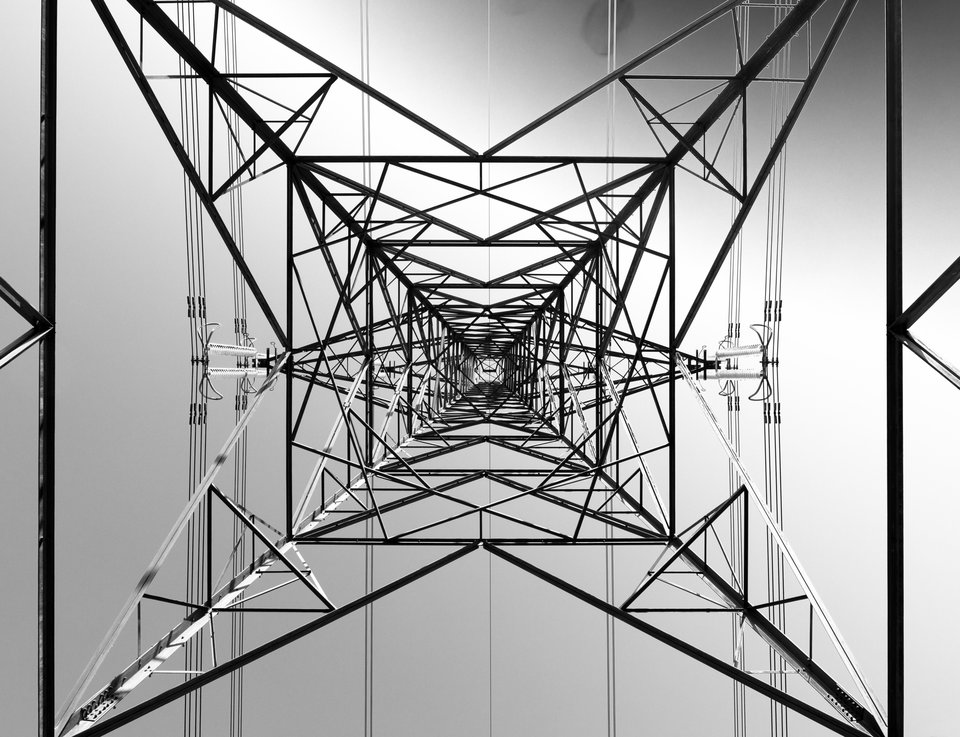

The work of Burdyny & Smith and Ramirez Ramirez are excellent examples of the e-Refinery approach. Burdyny: “Changing our energy system is an immense challenge. It requires breakthroughs at the scale level smaller than a human hair up to the scale of entire countries. Collaboration between science and industry and between multiple disciplines is essential. This is the approach of the e-Refinery initiative.”

The e-Refinery was established to make the process of electrification of the chemical industry possible on all fronts. In consultation with Dutch industry, it was decided to start with three bulk chemicals: hydrogen, formic acid and ethylene. After that, the electrochemical production of methane and methanol, carbon monoxide and ammonia will also be examined at larger scales. Only through such an electrification will fuels become CO2 neutral in the future.

This objective of the e-Refinery is inextricably linked to that of smart electricity storage. By integrating the two sectors, surpluses or shortages can easily be exchanged between electricity-consuming industry and electricity suppliers. To achieve both objectives, the e-Refinery follows an integrated approach; from material design in the laboratory to integration in large-scale systems. Ramirez Ramirez concludes: “Preventing disastrous climate change is a race against time. It requires international cooperation and technological development as we have never seen before.”

Paulien Herder

Paulien Herder is professor Energy Systems at TU Delft and program leader of e-refinery.

“Our goal is to pave the way to the production of fuels and resources from CO2 with the help of sustainable electricity. E-refinery offers a number of promising technologies that will enable us to use CO2 as a raw material for our chemical industry, instead of oil, gas and coal. The products that we are going to create along this electrochemical path can subsequently also be used as a long-term storage medium for sustainable electric energy and as CO2-neutral transport fuels. The e-Refinery technology will thus play a key role in the transition to a climate-neutral society”