Nanostructured Materials Production using Aerosol-Based Methods

The Goal

Synthesis of particles 0.5 – 50 nm in diameter out of virtually any inorganic material and production of nanostructured materials using aerosol-based methods

- Advantages:

- Arbitrary mixtures of materials possible

- No waste production

- No chemical precursors needed

- High purity, no surfactants

- Applications

- Sensors

- Photoelectrochemical water splitting

- Catalysts

- Batteries

- Supercapacitors

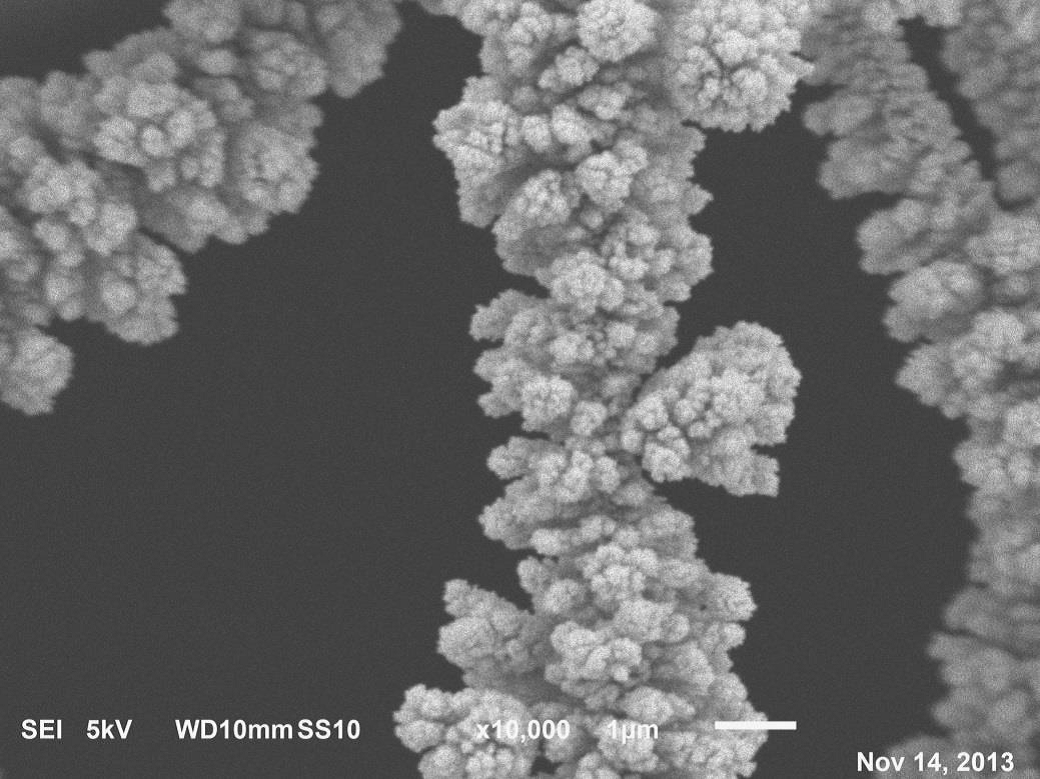

- Functionalized nanofibers and textiles

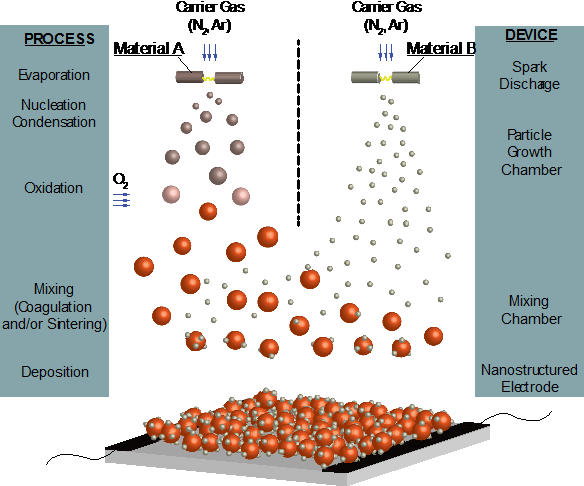

The Concept

We produce highly concentrated clouds of metal or semiconductor vapors which are subsequently cooled in a controlled manner to form nanoparticles. A convenient way of doing this is by spark ablation, where microsecond discharges between electrodes produce particles of the electrode material in the atomic cluster or nanometer size range. These are focused deposited or broadly spread onto surfaces adequate for any specific application.

Related Current Research Activities

- Optimizing nanoparticle productionChemical sensor production (with George Biskos, CiTG)

- Establishing a new concept for catalyst production by assembling both the high surface area substrate and the active component(s) from nanoparticles in one process

- Enhancing the efficiency of photoelectrochemical water splitting using nanoparticles (with Wilson Smith)

- Producing alloyed magnetic nanoparticles for application in drug delivery (with Ekkes Bruck, RID)

- Nanoparticle detection and characterization in gases (with George Biskos)

- Determining the toxicity of nanoparticles (with George Biskos, Albert van den Berg, Twente and Federal Institute for Occupational Safety and Health (BAuA), Berlin)

Industrial Cooperation and Spin-offOur spark ablation process has become the main focus of the EU project “BUONAPART-E “(FP7), where, together with 20 partner institutions we are successfully demonstrating its practical use in six exemplary applications ranging from high-tech (solar cells, nanophotonics) over specific functions (functional textiles, catalytic reactors) to high-volume (nanocomposites, nanofluids for cooling steel manufacturing plants).

At the end of 2014, Aaike van Vugt (former MECS Master student), Tobias Pfeiffer (former MECS Ph.D. student) and Andreas Schmidt-Ott (prof. in MECS) founded the company VSParticle. Based on 2 patented methods of spark ablation and nanoporous materials production, VSParticle has the goal of fully exploiting the potential of inorganic nanoparticles by offering a simple process to industry for their production and integration into materials and devices.