Multifunctional performance through microstructural design and functional grading

Functionally graded materials (FGMs) are a new and robust class of materials, which exhibit spatial variations in composition and microstructure; created for the specific purpose of achieving local enhancements in mechanical, structural or other functional properties. To date, most of the reported solutions are limited to 1D (unidirectional) gradients in relatively simple shapes. The question arises whether we can create materials within materials with multi-dimensional spatial distributions within a structure.

The unlimited combination of mixed metals in a single part offered by additive manufacturing is unlike any other conventional fabrication method and creates a unique opportunity to use chemical composition and tailored microstructures as design parameters, that can create unique functionally graded parts (e.g., materials with high hardness in one area and improved wear and/or corrosion resistance in another).

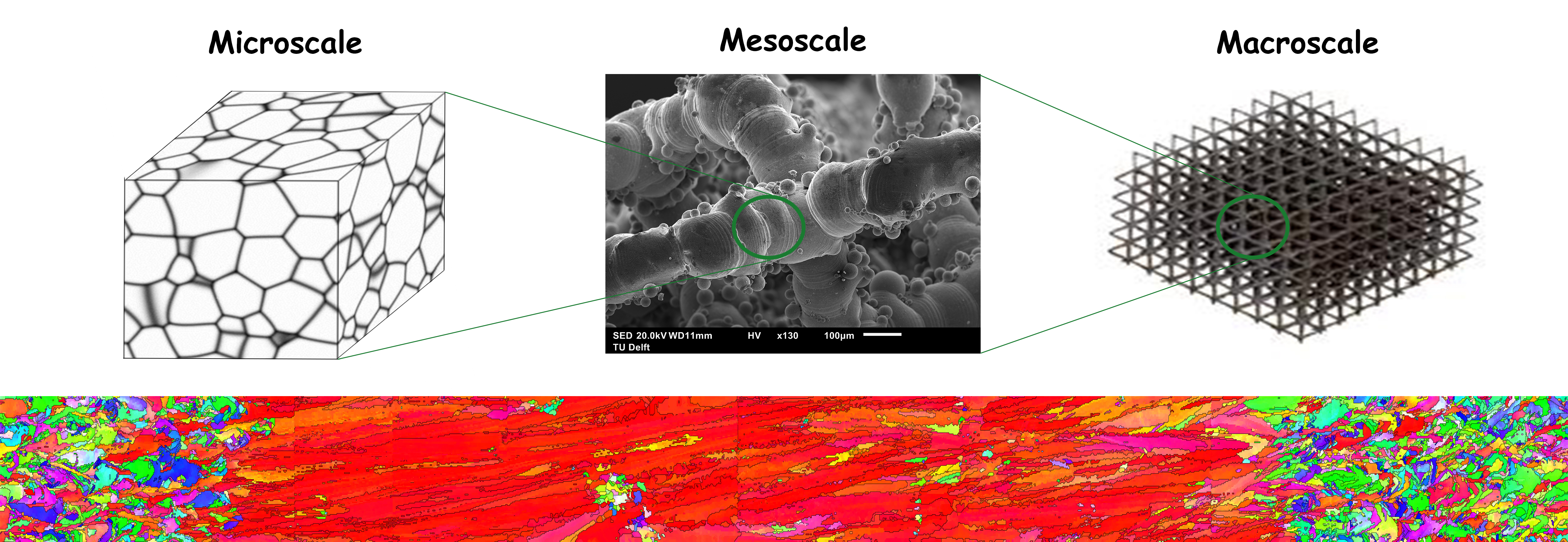

The number of possibilities is enormous, but so far there are have been no systematic studies looking into the properties of 3D metallic FGMs. Clearly, in order to move forward, there are a number of challenges that need to be addressed, including those associated with fundamental understanding of microstructure – effective property relationships and fracture behaviour of such complex materials. Furthermore, there is a lack of understanding involving multi-physics responses and interactions occurring at multiple length scales, which is the main scope of this research theme.

Current research projects:

C1. Functionally graded Inconel 718 processed by additive manufacturing

Additive manufacturing offers a unique way of anisotropic microstructure control with high design freedom. This study demonstrates that application of a suitable laser scanning strategy and laser source may favour either one sharp single component texture, more uniformly distributed crystal, or a combination of the above in a preferred gradient, which influence the mechanical properties.

C2. Microstructural Design of Lattice Titanium Structures

Ti-based alloys are finding ever-increasing applications in medical and aerospace applications due to their superior performance. However, mechanical properties, long-term performance and durability of additive manufactured Ti-alloys has raised some concerns. In this project we will investigate the additive manufacturing process, microstructural design and associated macroscopic mechanical properties of micro-lattice structures comprise of Ti-6Al-4V alloy. The aim of the project is to develop porous Ti-6Al-4V components with enhanced mechanical properties by better understanding the effect of process parameters on the local temperature evolution and microstructure.