Chair gas turbines for power generation

Gas turbines are high tech, high efficiency engines that convert chemical energy into work. Their high power to weight ratio make them the engine of choice for aircraft propulsion. Gas turbines are also at the heart of all modern gas fired power stations making electrical efficiencies above 60% possible. Beside the high power to weight ratio and the high cycle efficiency other advantages of gas turbines are the low emissions, the flexibility in operation and the applicability of the high grade waste heat either in a bottoming steam cycle or for industrial objectives.

Zero carbon emissions

The gas turbine chair of mechanical engineering focuses its research on zero carbon application of gas turbines and other advanced industrial thermodynamic cycles.

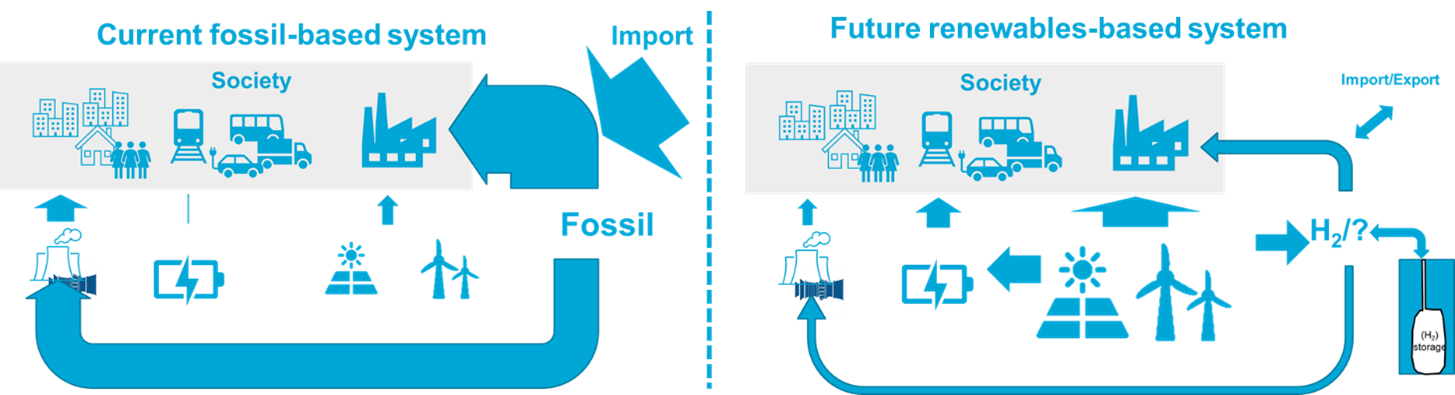

In the zero carbon electricity system, driven by renewables, gas turbines play a pivotal role for balancing the grid during periods of shortage of renewable generation and to provide long duration energy storage in combination with green hydrogen. The fuel for gas turbines will shift from natural gas to zero carbon fuels like hydrogen. Moreover other thermodynamic cycles will develop in the future energy system like pumped thermal energy storage and heat pump technology driven recycling of heat in industrial processes.

Gas Turbine chair

The Gas Turbine chair at the department of Process and Energy of Mechanical Engineering at the TU Delft has a long history in delivering high level education and world class research in the field of gas turbines. The chair is financially supported by the SGO (Stichting Gasturbine Onderwijs) and has excellent relationships with the Dutch and international gas turbine industry.

Research themes

Education

The chair is responsible for the MSc course: Turbomachinery (ME45170, 4 ECTS). The course is delivered by Prof. Dr. Ir. S.A. Klein and Prof Dr Ir R. Pecnic.

Resources

Interview TU Delft, 2018, Gas Turbines: essential for the transition to renewable energy sources

Gasturbine, het succes van kleine stapjes, Energeia 2021, https://energeia.nl/energeia-artikel/40077015/gasturbines-het-succes-van-kleine-stapjes

Hydrogen combustion in gas turbines 2021, Webinar Dutch Section of the Combustion Institute

Retrofit Delesto 2 warmtkracht centrale naar start/stop met geavanceerde start up procedure, 2022 https://www.chemieparkdelfzijl.nl/actueel/2022/06/1050485-meer-dan-honderd-opstarts-van-delesto2

Riddhi Kapoor winnaar Nederlandse Gas Industrie research prijs Juryrapport-Nederlandse-Gasindustrieprijzen-2022.pdf (khmw.nl)

Flexible and efficient electrification of the industry, 2023 Flexible and efficient electrification of industry - Industrial Heat & Power (industrialheatandpower.nl)

Aanbodgestuurde productie maakt elektrificatie mogelijk https://verduurzamingindustrie.mett.nl/actueel/nieuws/2397960.aspx?t=Aanbodgestuurde-productie-maakt-elektrificatie-mogelijk

“Flexibiliteit en efficiency moeten hand in hand gaan” https://inzicht.vemw.nl/magazine/vemw-inzicht-nr-2-2023/flexibiliteit-en-efficiency-moeten-hand-in-hand-gaan/

Journal publications

A. Gangoli Rao, F.S.C. van den Oudenalder, S.A. Klein, Natural gas displacement by wind curtailment utilization in combined-cycle power plants. DOI:10.1016/j.energy.2018.11.119

A. Nannarone, S.A. Klein: Start-Up Optimization of a CCGT Power Station Using Model-Based Gas Turbine Control, Journal of Engineering for Gas Turbines and Power 10/2018; 141(4)., DOI:10.1115/1.4041273

M. del Grosso, B. Sridharanb, C. Tsekosa, S. Klein & W. de Jong, A modelling based study on the integration of 10 MWth indirect torrefied biomass gasification, methanol and power production, Biomass and Bioenergy, Vol 136 May 2020, https://doi.org/10.1016/j.biombioe.2020.105529

Bjornson, O.H., Klein, S.A. and Tober, J., Boundary layer flashback model for confined hydrogen flames including the effect of adverse pressure gradient flow, Journal of Engineering for Gas Turbines and Power 2020, GTP 20-415, https://doi.org/10.1115/1.4048566

Schöffer, S.I. , S.A. Klein, S.A., Aravind, P.V., Pecnik, R., A solid oxide fuel cell- supercritical carbon dioxide Brayton cycle hybrid system, Applied Energy, 2020, 115748, https://doi.org/10.1016/j.apenergy.2020.115748

Mulder S, Klein S. Techno-Economic Comparison of Electricity Storage Options in a Fully Renewable Energy System. Energies. 2024; 17(5):1084. https://doi.org/10.3390/en17051084

Conference publications

S. Klein: ON THE IDENTIFICATION OF COMBUSTION INSTABILITY MECHANISMS IN INDUSTRIAL GAS TURBINE COMBUSTORS. 1st Global Power and Propulsion Forum, Zurich; 01/2017

Steimes, J., Klein, S., & Persico, M. (2018). Enabling efficient and low emissions deep part load operation of combined cycles and combined heat and power plants with external Flue Gas Recirculation. Proc Glob Power Propuls Soc, 18., https://gpps.global/wp-content/uploads/2021/01/GPPS-Zurich18-0013.pdf

V. Prakash, J. Steimes, D. J. E. M. Roekaerts, Sikke Klein: Modelling the Effect of External Flue Gas Recirculation on NOx and CO Emissions in a Premixed Gas Turbine Combustor With Chemical Reactor Networks. ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo; 06/2018, DOI:10.1115/GT2018-76548

A. Nannarone, S.A. Klein: Start-up Optimization of a CCGT Power Station Using Model Based Gas Turbine Control. Proceedings of ASME Turbo Expo 2018 - The 2018 Turbomachinery Technical Conference & Exposition presented by the ASME International Gas Turbine Institute, Lillestrøm (Oslo), Norway; 06/2018, DOI:10.1115/GT2018-76230

J. Steimes, M. Persico, S. Klein: Enabling efficient and low emissions deep part load operation of combined cycles and combined heat and power plants with external Flue Gas Recirculation. GPPS Forum 18 - Global Power and Propulsion Society, Zurich; 01/2018

S.A. Klein, F.van Deursen: Evaluation of the Optimum Hybrid Power to Heat Configuration for a Gas Turbine Based Industrial Combined Heat and Power Plant. ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition; 06/2019, DOI:10.1115/GT2019-90946

Bjornson, O.H., Klein, S.A. and Tober, J., Boundary layer flashback model for confined hydrogen flames including the effect of adverse pressure gradient flow, ASME Turbo Expo 2020, GT 2020-14164

Schouten, B. and Klein, S.A. Hydrogen and oxygen fired turbine cycle optimization , ASME Turbo Expo 2020, GT 2020-14592

Kapoor, RR, & Klein, S. "Innovative Cycles for Industrial Combined Heat and Power Generation With Carbon Capture and Storage." Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition. Volume 4: Cycle Innovations; Cycle Innovations: Energy Storage. Rotterdam, Netherlands. June 13–17, 2022. V004T06A008. ASME. https://doi.org/10.1115/GT2022-80697

Klein, S, & Sarakatsanis, C. "Validation of Hydrogen Boundary Layer Flashback Model on Gas Turbine Geometries and Conditions." Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition. Volume 3A: Combustion, Fuels, and Emissions. Rotterdam, Netherlands. June 13–17, 2022. V03AT04A013. ASME. https://doi.org/10.1115/GT2022-79816

Gruber, A., Heggset, T., Meyer, O., Altenburg, L., Tummers, M., Klein, S., ... & Stuttaford, P. (2023, June). Numerical and Experimental Investigation of a Geometrically Simplified, Two-Dimensional FlameSheet™ Hydrogen Burner. In Turbo Expo: Power for Land, Sea, and Air (Vol. 86960, p. V03BT04A054). American Society of Mechanical Engineers., https://doi.org/10.1115/GT2023-103779