Research

Objectives

- Developing and implementing computational models for the simulation of the static and dynamic response of various pavement materials, including asphalt concrete, granular bases, soil, liners, and reinforced systems.

- Establish a more fundamental understanding between the chemistry and the mechanical and rheological properties of bituminous materials (and similar materials).

- Develop newer and more reliable monitoring techniques to assess the condition of asphaltic materials.

- Evaluate how the use of recycled asphaltic materials in the production process can impact the quality of pavements.

- Establish a standardized model to effectively produce and monitor the impact, quality, durability, and performance of recycled pavement materials.

- Developing sustainable materials and structures to replace conventional pavement materials, including the use of greener additives.

- Extend the durability and performance of asphalt surfaces using novel rejuvenators.

- Improve the techniques used to produce hot, warm, and cold asphalt concrete mixtures effectively and efficiently.

- Use the research performed on bituminous materials to aid other research projects involving other complex materials (e.g., colloids, metal-organic frameworks, catalysts, etc.)

Research Topics

- Mechanics of multiphase media.

- Experimental testing and constitutive modelling of pavement materials.

- Pavement analysis & design.

- Molecular Dynamics and Coarse-Grained Force Field Dynamics modelling of bituminous materials.

- Multi-physics flow and damage phenomena in asphalt mixtures

- Non-linear finite element analysis techniques.

- Experimental testing and constitutive modelling of pavement interlayer systems.

- Multilayer asphalt surfacing systems on orthotropic steel deck bridges.

- Micromechanical constitutive modelling of asphalt concrete.

- Induction healing technology for asphalt concrete application.

- Warm/cold rubberized asphalt concrete technology.

- Recycling asphalt concrete.

- Epoxy asphalt concrete.

Experimental

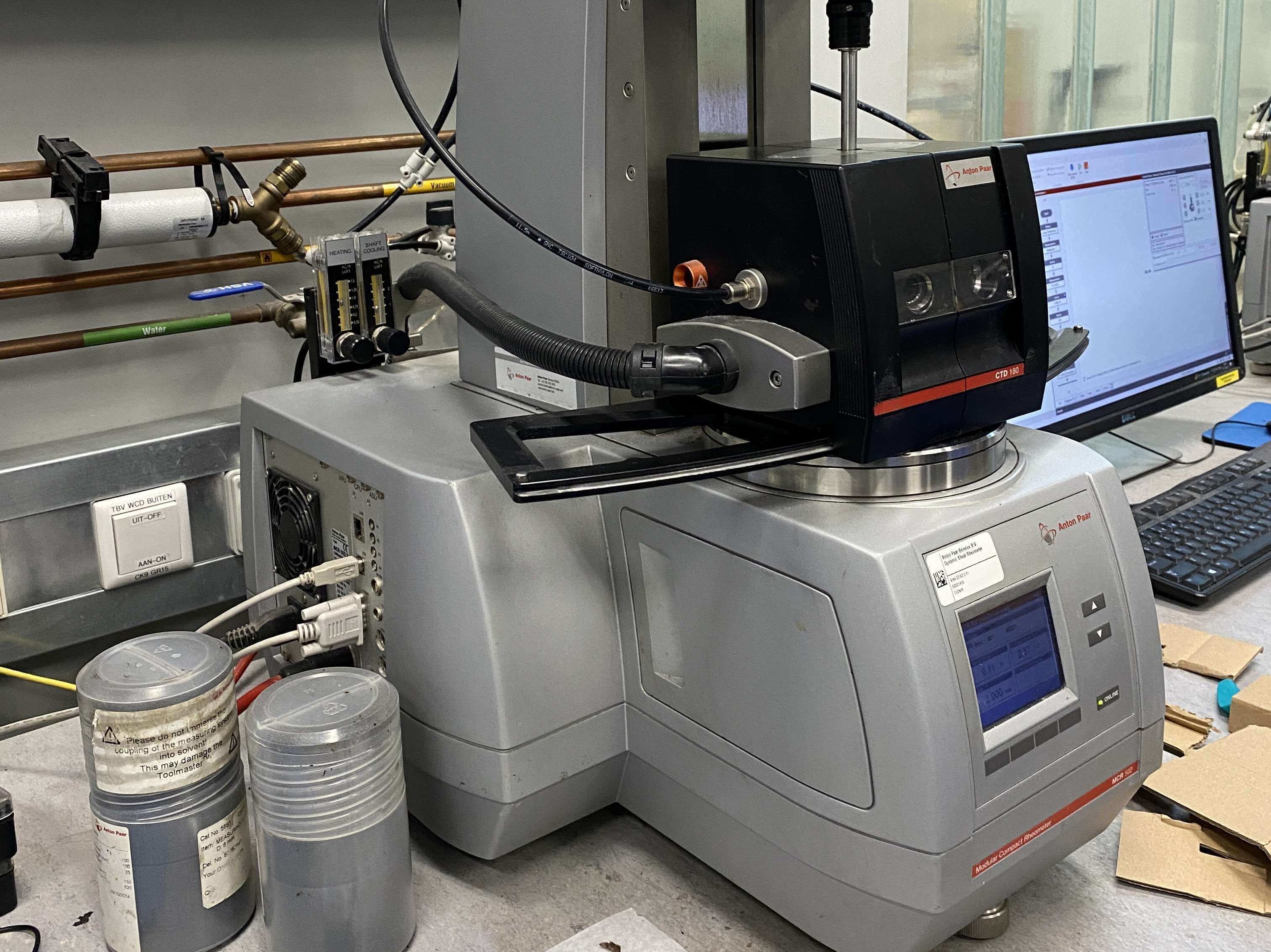

The lab we use is part of the Pavement Engineering section at Engineering Structures Department at TU Delft. It is equipped with the latest and most advanced tools to perform research spanning over multiple size domains. We can perform a number of chemical, rheological, and mechanical stress tests, allowing us to evaluate the quality, performance, and durability of a multitude of bituminous materials, asphalt concrete mixtures, and specimens ranging from a few millimetres to a few meters in size. The lab is also equipped with state-of-the-art conditioning devices to expose samples to realistic environmental conditions (e.g., short- and long-term aging, moisture, ultraviolet light), allowing us to produce results that are effectively relevant to field applications. Our group maintains tight ties with other laboratories and research facilities in the country, allowing us to perform an even broader set of experiments with ease. The following is a list of the devices available to the members of our team.

Computational

Our group has placed a considerable amount of effort in employing computational methods to develop a more thorough and realistic model of bitumen. This is done to successfully link fundamental chemical characteristics and the mechanical and rheological properties of bitumen. However, modelling all these features has been remarkably challenging. Unlike other materials, bitumen is highly complex. It is composed of thousands of dissimilar molecules whose interactions form characteristic nanostructural and microstructural features.

Current use of atomistic simulations and finite elements methods have been proven to be useful, although insufficient in recreating all the interesting phenomena that are known to occur in systems involving bitumen. Our group is compelled to develop state-of-the-art computational methods to develop a more comprehensive and realistic model of bitumen. A model that results in findings which are relevant to both engineering applications and to research involving fundamental studies. The Structural Engineering Department (and thereby, all our group's members) have full access to DelftBlue, a High-Performance Computer at TU Delft with access to a theretical maximum of 11000 CPU cores! Follow this link for more information.