Demountable and fatigue resistant connectors for fibre-polymer composite decks in hybrid bridges.

In recent years, fibre-polymer composite sandwich panels with or without interconnected webs, have revolutionized numerous high-performance applications due to their unique fatigue and corrosion resistance and lightweight yet robust construction. Their versatile use extends from enabling lightweight design in the aerospace and automotive sectors to enhancing the resilience of wind turbine blades in the renewable energy industry.

Building on their broad applications, in mid 1990s the use of sandwich panels made out of fibre-polymer composites has permeated the field of bridge construction and bridge renovation. However, the lack of a universally accepted, efficient, and predictable connection technology represents a significant barrier to the broader application of composite decks in the infrastructure sector. Recognizing the necessity for robust connection methodologies, industry and academia have investigated and developed bolted and bonded solutions to integrate composite deck panels in bridge construction. Bolted connections, though simple and adjustable, can induce stress concentrations and compromise the integrity of the composite material. Bonded connections, while capable of distributing loads more evenly and maintaining the material’s holistic integrity, can pose challenges with regard to long-term durability, inspection, and quality control.

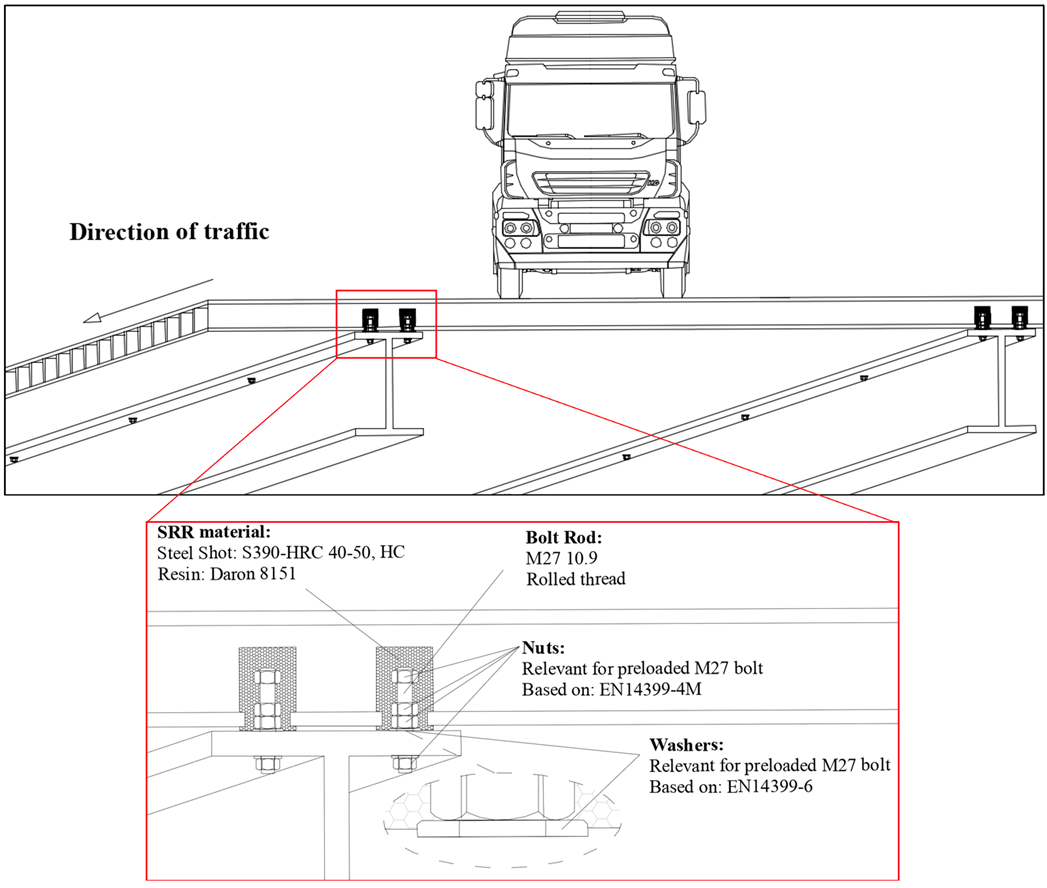

A promising advancement in bridge construction technology is the introduction of the injected Steel-Reinforced Resin (iSRR) connector, designed for Glass Fibre-polymer composite (a.k.a GFRP) deck panels in hybrid steel-FRP bridges. As shown in Figure 1, the iSRR connector is demountable. It comprises double nuts (or a coupler) on a bolt/rod embedded within an cavity in FRP composite deck, filled with steel shot particles and polymer resin. The iSRR connector leverages the enhanced properties of SRR injection material to form a resilient and fatigue-enduring connection by combining bolt preloading and injection, offering flexibility with options for prefabrication or on-site construction. Preliminary fatigue performance evaluations through experiments have demonstrated an impressive initial stiffness, shear resistance, and ultimate slip at failure, with fatigue endurance under fully reversed cyclic loading about 100 times greater than traditional bolted and injected connections for FRP composites.

Figure 1: iSRR connector embedded in a GFRP sandwich panel connected to steel girder.

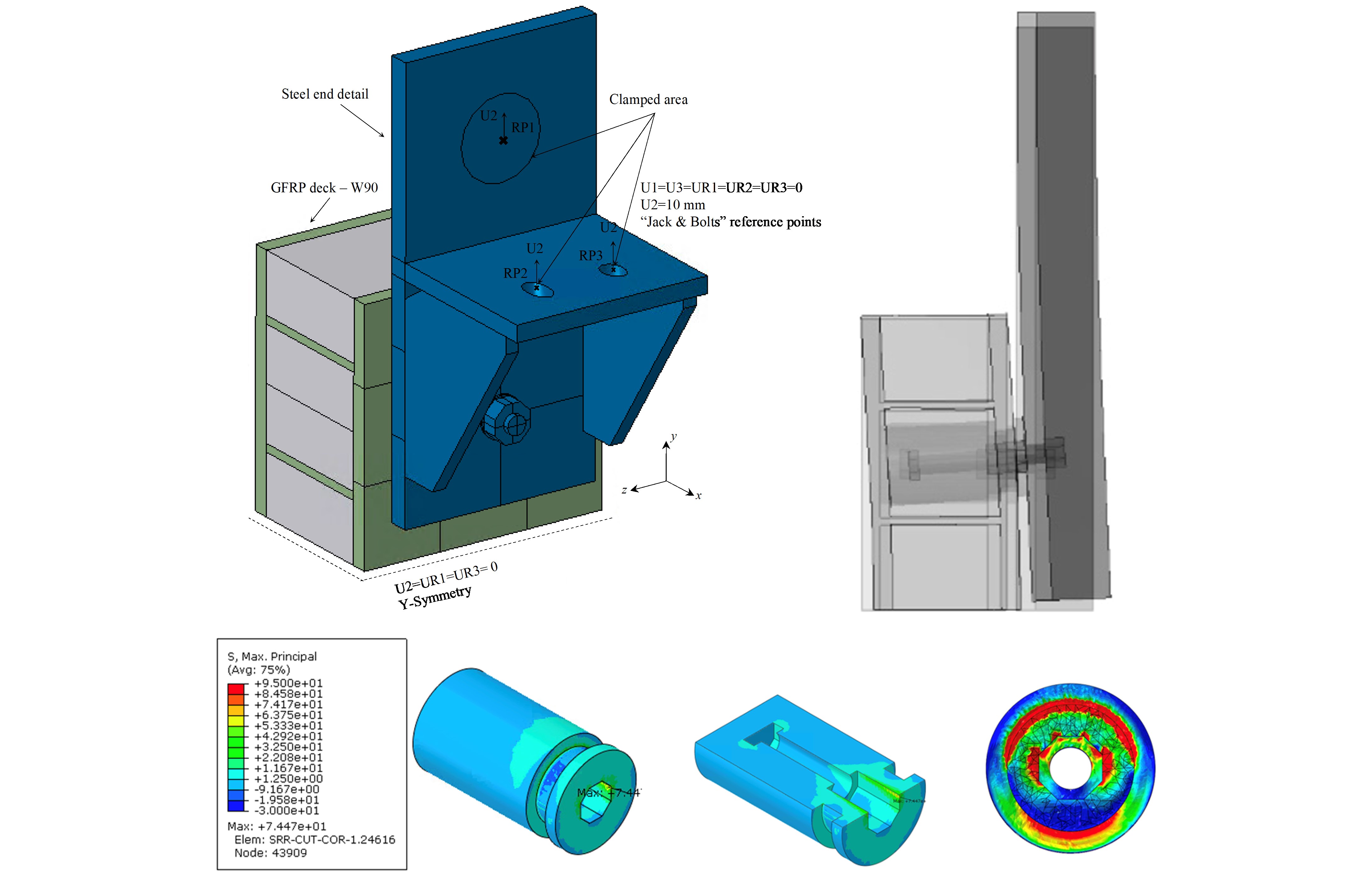

A four-year research project, initiated in November 2020, is currently underway. The project's primary objectives are twofold: to design a small-scale test setup (segment) for investigating the fatigue performance of iSRR connectors in composite-steel highway bridges, and to advance knowledge in predicting their behaviour. To date, the majority of the necessary experiments on these connectors have been successfully conducted. This has yielded a significant collection of experimental data and preliminary results in form of F-N curves at room and elevated temperature that can be expected in bridge decks. Concurrently, Finite Element Models have been developed to understand potential damage mechanisms that contribute to fatigue degradation, as illustrated in Figure 2.

Figure 2: Finite Element Modelling of stress concentrations in iSRR connector.

For further information, please contact:

Dr. M. Pavlovic (m.pavlovic@tudelft.nl)

Ir. A. Christoforidou (a.christoforidou@tudelft.nl)