Yuri Sebregts

“The Netherlands was created and developed by utilising wind and managing water for many centuries. This continues into the future. It is a fluid flow country at its core. World class expertise in fluid flow science and technology provides an exciting opportunity to support governments, industries, and societies with the required knowledge to make the energy and circularity transitions happen, at home and abroad. For the Netherlands, fluid flow technology is an export product with purpose.”

Yuri Sebregts

Executive Vice President Technology and Chief Technology Officer, Shell

Fluid flow for the energy transition

Fluid flow at Shell.

The landscape and water architecture of the Netherlands demonstrate the Dutch world class leadership in the science and engineering of fluid flow. We all recognise the historical wind mills and their role in reclaiming land. The same fluid flow principles are also applied in Shell’s process industry, involving the transport and conversion of gasses, liquids and solids via complex pipelines, separators, pumps, compressors, and reactors.

As it is time for change, collaboration among all stakeholders is required to develop the know-what and knowhow to obtain a worldwide clean and sustainable energy system. Fluid flow is at the heart of the hydrogen value chain (production, transport and use), manufacturing of synthetic fuels (like kerosine for aircraft), and carbon capturing and storage.

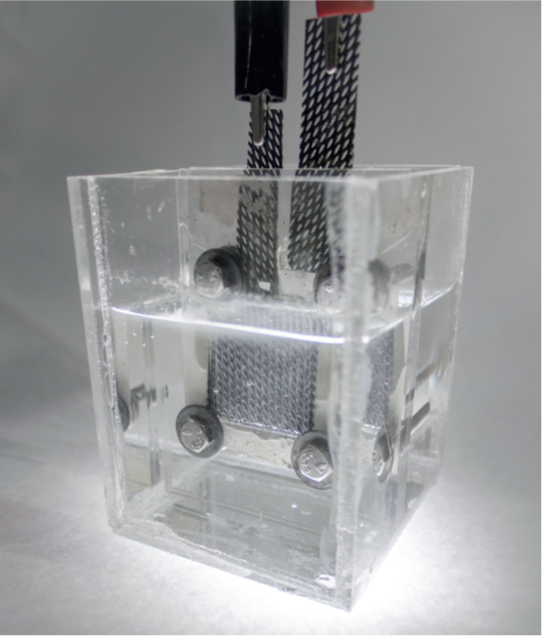

Shell sees great potential in hydrogen production. Electrolysis of water to make hydrogen is a well-known principle, with significant opportunities for further optimisation. The electrochemical process in a low temperature electrolyser generates a flow of hydrogen and oxygen bubbles in the water solution between the electrodes.

What is the optimum design of the flow configuration that gives minimum energy losses? And how to convert the lab testing into pilot testing, and scale up to industrial sizes, including storage and transport? The fundamental knowledge at the interface between materials, electro-chemistry and fluid flow will be required for new breakthroughs like high-temperature high-pressure electrolysis.

Next to the potential of hydrogen, CO2 capturing, transport, and storage at large scale is part of the strategy to reach net-zero emissions in line with the Paris Agreement on climate change. How can CO2 most efficiently be captured from the air, from water, from process gases? Single phase transport and multiphase transport under turbulent flow conditions is a mature field for many fluid types. However, the complex thermodynamic properties of CO2 have initiated new Shell research, with lab testing, computer simulations, field testing and deployment to unlock the full potential of CO2 storage for the future ahead.