What if agricultural waste such as oil palm trunks can be turned into high values products such as biofuels? Experimental research by Delft University of Technology and Guatemalan partners using hydrothermal liquefaction is yielding promising results. TU Delft | Global Initiative is looking to broaden its impact.

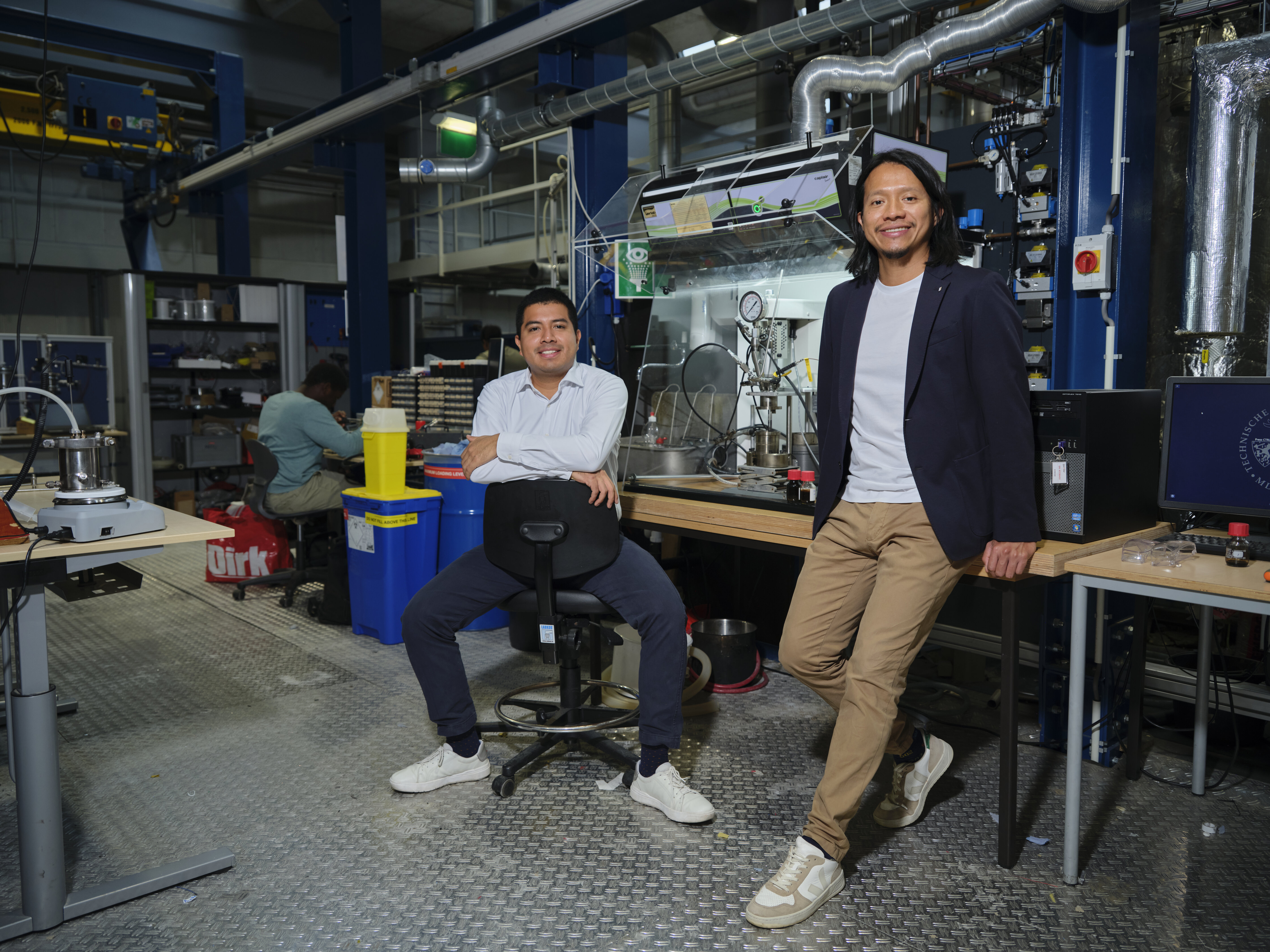

“Valorisation of residues from agricultural production is an effective way of achieving a more sustainable agricultural sector and food chain”, says Luis Cutz, a chemical engineer from Guatemala. After obtaining a PhD degree in Spain on the subject of biomass energy systems, he moved to Delft University of Technology in 2018 and is currently employed as an assistant professor at the Large-Scale Energy Storage section (LSE) of the Process and Energy department. “The LSE group specialises in process and reactor design for the conversion of biomass or waste streams into products of higher value such as biofuels, chemicals and biomaterials.” During these past four years, Luis has been particularly concerned with the research and development of technologies that support the conversion of biomass into solid and liquid biofuels.

It’s all about addressing global challenges whilst pursuing positive local effects.

Oil palm trunks

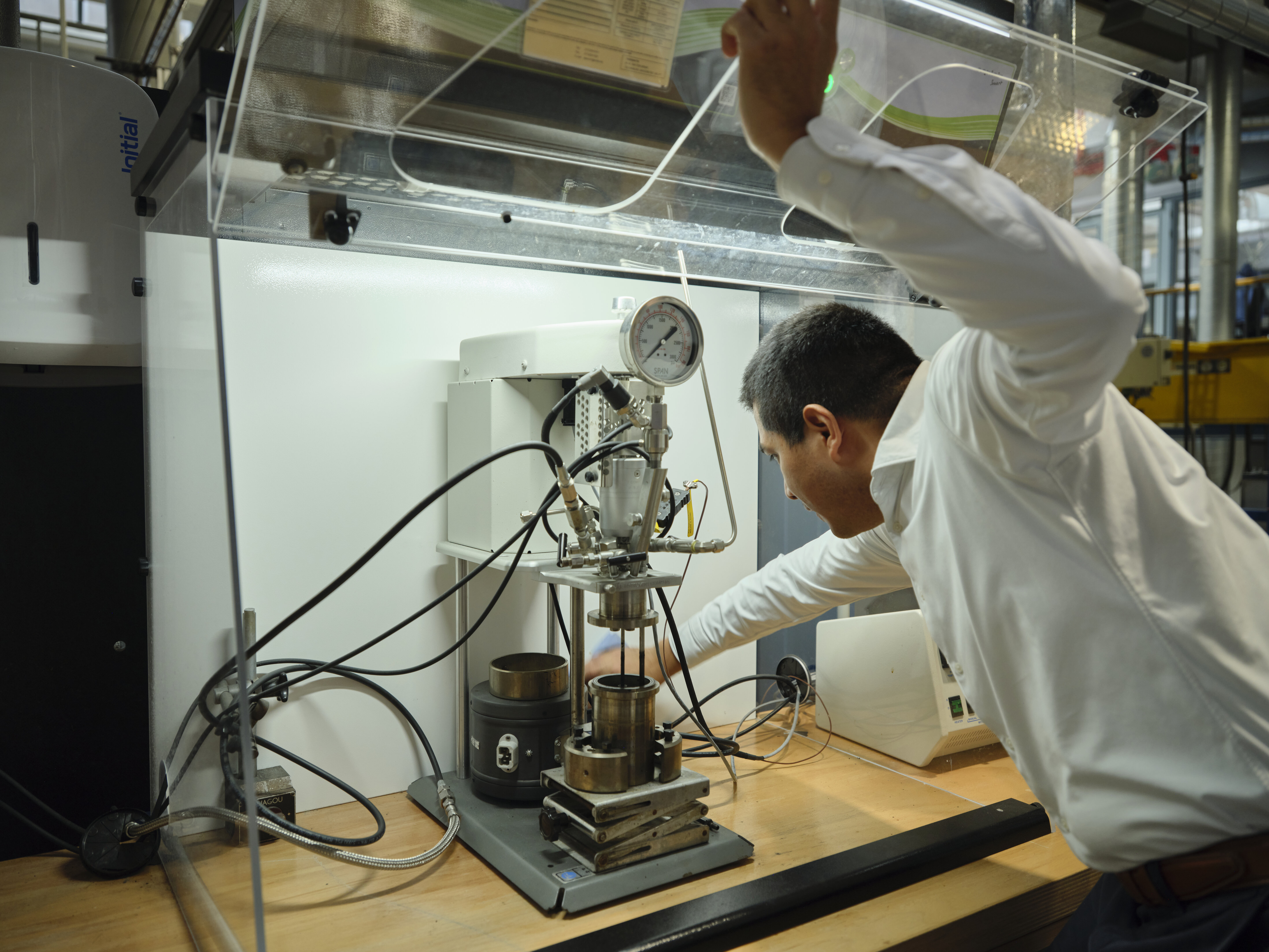

Two years ago, one of Luis’ former master students and fellow Guatemalan Héctor Maldonado told him about his bachelor thesis dealing with the valorisation of residues from the palm oil industry. “The trunk has a high moisture content of about 70 percent which is a challenge when applying a conversion process called pyrolysis, which decomposes materials at elevated temperatures without oxygen.” Pyrolysis is used worldwide to produce fuels from biomass and plastics. However, it requires a lot of energy to reach very high temperatures. “Our group head Prof. dr. ir. Wiebren de Jong and I were working on a different technology called hydrothermal liquefaction, or HTL, and offered to try it out.” HTL is a thermochemical process through which wet biomass is converted into multiple products, but mainly biofuel, under moderate temperature and high pressure.

First results

Guatemalan soil is very fertile, highly suitable for the production of coffee, sugar, bananas and palm oil. In 2021, the Guatemalan palm oil industry was the sixth largest and relatively most productive in the world, covering some 1806 km² of plantations. “The crop has an economical lifespan of around 25 years, after which new trees are planted next to the old trunks, which are left in the field. The growth rate of the new trees is actually decreased by the presence of the old ones, research has shown. So planters can benefit from having the old trunks removed and converted into valuable products.”

A research project was set up in collaboration with Universidad del Valle de Guatemala and GREPALMA, an association of palm oil growers committed to the responsible cultivation of oil palms. GREPALMA provided trunk samples while researchers at the Universidad del Valle de Guatemala pre-treated the trunks into smaller pieces which were sent to TU Delft where Luis, Héctor and Wiebren conceptualized the experimental method. Then, Héctor performed different HTL experiments and together with Luis analysed the products of the HTL process. “By the summer of 2022 we were able to produce a biofuel from the trunk, which can be used for transportation purposes or the production of electricity.” The fuel yield is actually higher than with pyrolysis, says Luis, and uses lower temperatures which makes HTL a potentially more cost-effective conversion technology. “Apart from the biofuel as the main product, the process also generates biochar, a high-carbon by-product that may serve as soil amendment or be used in advanced products such as sensors. Plus, the gas phase can be turned into a biogas.” These advantages of HTL over pyrolysis – that it can handle high moisture content feedstocks and deliver multiple high quality products – increase the chance of profitability for those who seek to apply the technology commercially.

A more sustainable industry requires a multidisciplinary approach.

Opportunities

Luis now regards HTL as a potential game changer, a technology able to make the palm oil industry much more sustainable when applied on a large scale. However, whether biomass conversion is in any way commercially viable doesn’t just depend on the conversion process itself. Local supply chains are key to any circular economy, says Luis. “Much depends on whether it is economically viable to collect and process the trunks. Can resulting biofuels and biochars be used advantageously? If there’s no driver for the development of HTL-based biorefineries, it might be hard to reach a solid business case for converting this biomass.”

Luis believes opportunities are provided by the industry itself. Using the biofuel produced from the trunks for transport could be a worthwhile goal to further pursue, he thinks, not just from a business point of view, but also to reduce CO2 emissions. “Likewise, the biofuels might be used to replace part of the fossil fuels that power the palm oil processing plants. Why not have a biorefinery next to the processing plant? The biochar can probably be applied as a sustainable soil amendment. That is certainly worth examining as half of the palm oil industry’s CO2 footprint results from the use of fertilisers.”

Hot topic

Within one of the flagship projects of the TU Delft Climate Action Programme, Luis will be applying HTL to waste plastics, another global challenge, aiming to obtain either a fuel or a virgin polymer. Waste plastics are mainly being recycled mechanically, usually by sorting, washing and shredding. “Each time this happens, the plastic is degraded a little further until it can’t be used anymore.” Thermochemical recycling of plastics offers a more sustainable pathway because basic components can in theory be retrieved and reused infinitely. Making it a truly circular process. “Keep in mind that still a lot of research is needed to unveil the performance of these conversion technologies and the quality of the products. Understandably, it’s a hot topic worldwide and any useful results are being received enthusiastically but it may well take ten years before we’ll have something tangible that can be applied on a large scale.”

Substantial impact

Meanwhile, Luis is keen to continue his research on thermochemical conversion of palm oil residues, not just trunks, as the technology developed at the LSE group could be replicated in other parts of the world leading to very substantial impact. Designing and realising a continuous HTL pilot plant in Delft features high on his wish list. "A more sustainable industry requires a multidisciplinary approach. With our technological focus – establishing which type of reactor works best, designing the process, assessing the quality of products – we can add to the efforts made by various partners in the Global South to improve the environmental and social impact of palm oil production. In this case by working towards more sustainable transport, land use or energy consumption.” Luis’s and Hector’s collaboration with Guatemalan partners and progress made so far have been picked up by TU Delft Global Initiative. This may lead to a more programmatic approach of innovative palm oil biomass valorisation, seeking collaboration with partners worldwide is now underway. "It's all about addressing global challenges whilst pursuing positive local effects."

Global Research Areas