New method for addressing challenges in the analysis of composite material

Themes: Materials, Structural Engineering

A TRL is a measure to indicate the matureness of a developing technology. When an innovative idea is discovered it is often not directly suitable for application. Usually such novel idea is subjected to further experimentation, testing and prototyping before it can be implemented. The image below shows how to read TRL’s to categorise the innovative ideas.

Summary of the project

Composite materials are plastics enriched with fibres which makes them light weight and strong at the same time. These materials are often used in the construction of aircrafts, wind turbine blades or even bridges. Despite the favourable qualities of the material it does not have an eternal life. Due to fatigue, small fractures and environmental ageing over time the material can tear or even break off. When this will happen is hard to tell. It is possible to make a prediction on a small scale but what about the complete length of the blade of a turbine? The researcher is working on developing a numerical method that predicts when such composite structure will break.

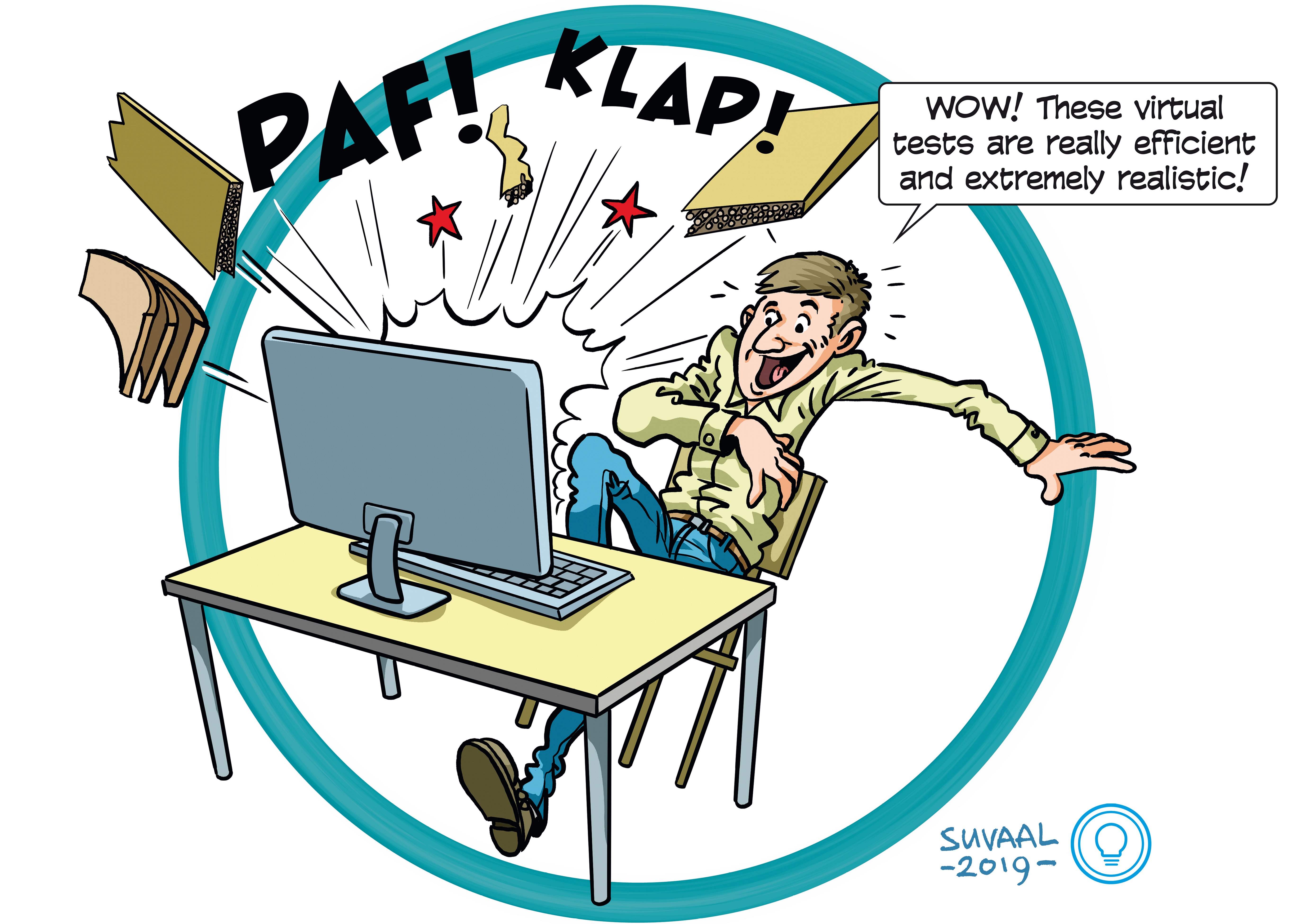

This research project is unique in the multi-scale computational mechanics approach applied to performance and the durability of composite materials. Normally such calculations take a lot of time. Through a model order reduction approach the researcher tries make such calculations more efficient. The model will lead to better understanding of what happens inside the material and contribute to the ability to optimally use the advantageous properties of composite materials in structural engineering.

What's next?

The next step for this research is to set up a machine learning system based on the multi-scale numerical models that the researcher is currently developing.

Dr. Frans van de Meer