How to convert the mechanical engineering competition into an online event

February 2020: the design project for all first-year Mechanical Engineering students gets underway. Approximately 88 teams of about 6 students are challenged to compete with each other to design a 'pack dog' capable of transporting a package weighing about 10 kg over various obstacles. The pack dog has to present a solution on how to deliver increasingly heavy packages. Students and teachers are working feverishly on the challenge, unaware that in a matter of weeks, the world is going to be turned onto its head.

Last year, Regine Vroom – who coordinates the course with her team – already explained in an interview why students are so enthusiastic about the design project and the design competition that concludes the project. ‘It’s a course that develops their practical skills. They learn effectively how to apply theory and solve problems themselves.’ So it was quite a shock, a few weeks after everything had started, for the current first-year students to learn that their design project would have to be revamped as a result of the coronavirus restrictions. Because if you’re no longer allowed to get together and work, and if you can’t build and test a design in the workshop, what can you still do?

Online, online and online again

There was no time to get disheartened about the situation. Regine Vroom and her colleagues had to come up with solutions as soon as possible to be able to continue teaching the project, but now online. ‘By then, the students had worked together in groups on the project tables in the faculty for almost five weeks and fortunately had already submitted the first part of the design report.’ Since then, the lectures and discussions with the project instructors have taken place online. The mandatory feasibility check – to assess whether the design can be built – was done digitally by the staff at the student workshop. The (open book) examination also took place online. Unfortunately, there was no alternative for the workshop instructions and welding instructions. These sessions will be caught up as soon as the students are allowed to return to the faculty. Indeed, anyone who didn’t follow these instructions won’t have access to the workshop, not even later.

From digital production drawing to design

Normally the students go into the workshop during the final quarter to produce their design and test the expected performance. Unfortunately, that can’t be done right now. But a solution has been found for that as well: the students are now being asked to further elaborate their design digitally and analyse it using simulations. This is done using the 3D-CAD software SolidWorks. The advantage is that students are now using this software, which is frequently used in mechanical engineering, more often and improving their skills with it. The groups also have to make a test plan and do a serial production assignment with their design. While it’s important that they learn how to design a prototype, it’s equally important that they learn how to manufacture a pack dog efficiently if it needs to be part of a serial production.

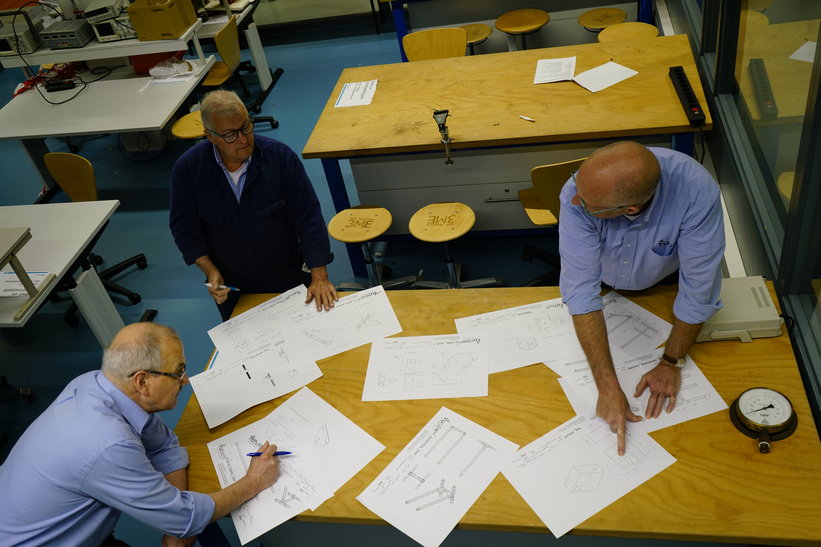

A number of designs have been selected to be used to physically produce pack dogs, not by students but by staff at the workshop. The challenge for the students is to make the production drawings in such a way that a design can be built without their being able to intervene. Gerard van Vliet, coordinator of the student workshop, explains: ‘In this case, we work as a production workshop. This means that the drawing must contain sufficient information to make the design. Each part that needs to be made has to be drawn, including the necessary materials and the assembly options.’

The students receive regular feedback through videos from the workshop that are published on Brightspace. They thus learn what works well and less well in their production drawings and how the manufacturing process works. ‘It’s instructive to show that not everything that has been conceived and that works and fits well in SolidWorks can be made or assembled in reality,’ says Gerard van Vliet. All students, including those who do not produce a design, are then asked to reflect on this manufacturing process.

Biggest challenge

Change is often met with resistance. Fortunately, there’s little sign of that in the design project. ‘The lecturers are all highly committed and are doing their utmost to keep the students involved, guide them and motivate them,’ says Regine Vroom. The students are also doing their best to make something of it. Some of them don’t always manage, purely for technical reasons, to get the SolidWorks program to work properly. ‘When the deadline for submitting the simulation assignment approaches, you notice the stress and frustration increasing a bit.’

When we speak to one of the student groups, they mention working together as the biggest challenge. ‘As we no longer see each other physically, we work less efficiently; when you’re actually together, it’s easier to discuss matters and work together,’ says one of the students. In any case, it’s not the fault of the background that you select on the Zoom online communication tool.

Confronting reality

Whether anything is going to happen on 17 June 2020, the original date of the design competition, is now being considered. ‘We’re looking into the possibility of having the student groups in question still test the small number of pack dogs that have been produced. Some of the students could, for example, take turns visiting the faculty,’ says Regine Vroom. One idea wold be to set up an online competition with the other groups’ simulation videos, from which no designs have been made, and have lecturers and judges from industry select the winners of the best designs.

‘We can't ignore the fact that things are different this year. But this, too, is mechanical engineering: you always have to confront reality and come up with alternative solutions for it.’ Nevertheless, she hopes – as do many others – that next year everyone can get together and make a huge celebration of it on campus, just like the good old days.

Teaser 1: The assignment

Teaser 2: The design

Teaser 3: The production