Its hardness and solidity make concrete a much-used building material. One of the most important ingredients of concrete is cement. Unfortunately, cement production comes with high levels of harmful CO2 emissions. That is why TU Delft researcher Guang Ye is looking for alternative binders such as pulverised household and building waste to reduce the impact on the environment. Ye and his team of colleagues and students intend to develop the most sustainable concrete in the world.

Bridges, dam walls, office buildings and apartment complexes are extremely solid and last a very long time, they all owe that to concrete. Concrete consists of a mixture of water, aggregate (crushed stone), and cement. The latter ingredient is particularly bad for the environment. With five to eight percent of the entire CO2 emissions worldwide, the cement sector is one of the peak polluting industries.

The high levels of CO2 are the result of two processes, says Guang Ye, associate professor of Materials and Environment at the faculty of Civil Engineering and Geosciences. “To make cement clinker (the intermediary product for cement) it is necessary to heat limestone to a temperature as high as 1400 degrees Celsius. During this process, limestone is decomposed which releases CO2. If we are serious about meeting the goals of the Paris Agreement on climate change the use of cement needs to be reduced drastically.”

The search for sustainable alternatives

At the same time, concrete is set to remain the building material of choice for housing, buildings and infrastructure, Ye says. The big question is how to make its production more sustainable. Ye: “To meet that challenge is my mission. I have been working in the area of construction materials for about twenty years now. I initially focused on the behaviour of cement. Then came the Paris Agreement and that was a turning point for me. Ever since I have been concentrating on finding sustainable alternatives, binders that release less CO2 and are largely renewable.

The cement industry has made some efforts to make the industry greener, for instance by CO2 capture and using sustainable energy for the production of cement powder. It is also using more environmentally friendly industrial by-products. Ye: “The two most important industrial by-products are blast-furnace slag and fly ash. The first is a by-product of the steel industry, and the second, which is released when burning coal, comes from coal-fired power plants.”

I’m looking for waste streams that will always be there.

Binders made from rubble and household waste

Metallic slag and fly ash are both industrial byproducts that will become scarce, because of the shutdown of coal-fired power plants, and the slow movement away from steel production. “That is why I am looking for waste streams that will always be there,” Ye says. “Waste from demolition, such as mineral wool and crushed fine fractions of construction demolished waste, biomass and household waste would be pretty constant. My research team and I are looking at the possibilities and restrictions of these streams as a source for binders. We have now charted these streams and put them in a database.”

Upgrading quality for use

To turn waste into a binder, it needs to be made into a powder, for instance by pulverising it. Ye then checks the chemical composition of each type of waste powder. “The composition of the powder determines its usability. We like to see the presence of a mineral such as calcium oxide, reactive silica oxide and aluminium oxide, for instance, but certain (heavy) metals on the other hand can impact negatively the quality of the powder. Those impurities will have to be removed first. We then activate the powder with alkaline, which produces a geopolymer binder.”

Turning waste into an alternative binder suitable for concrete is a big challenge, Ye says. “The trick is to use the right type and amount of activator. By looking at the molecular structure we know exactly how the atoms in different substances interact. A lot of work has gone into modelling and experimenting with different compositions at the lab in Delft over the last couple of years.”

Bridge made of geopolymer concrete

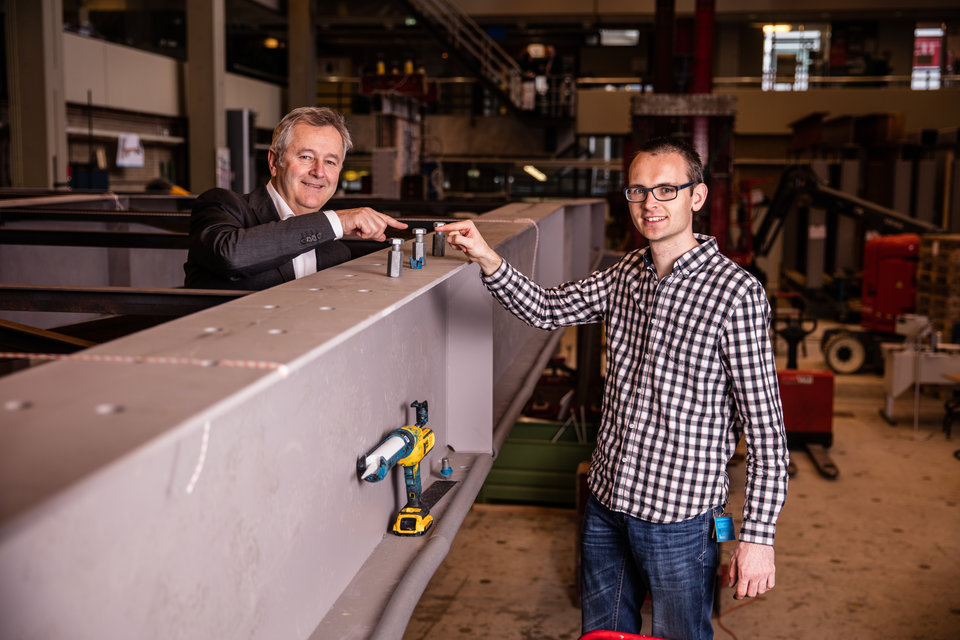

Ye and his team tested their findings during several projects. (see box, red.), one of which is a geopolymer concrete pedestrian bridge in Slaghaam in Rotterdam which was opened in June this year. Ye: “We were asked to build this bridge by the municipality of Rotterdam. The geopolymer concrete we designed was made from demolition waste, as was half of the aggregate material. That meant a big reduction in the use of raw materials and CO2 emissions.

Concrete needs to be both sustainable and strong.

The development of the geopolymer concrete mixture for the bridge took Ye and his team a few years. “Finding the right mix of ingredients was very time-consuming. The concrete needed to be sustainable but durable at the same time. We tested mechanical properties, volume stability, stiffness and long term durability properties. We also looked whether the concrete could withstand frost and thaw. In the end, we found that the most properties of geopolymer concrete are similar or outlasted the traditional cement-based concrete.”

On a mission to zero-emission

The most important result is the CO2 reduction, Ye says. “Contrary to cement combustion isn’t necessary to make geopolymer concrete. Studies have shown that geopolymer concrete is about sixty to eighty percent less polluting, depending on the precursors and activator used.

Ye is working hard to further scale down the emissions. Additional strategies are now being discovered, like reducing the amount of binder by optimal aggregate packing, and using carbon curing and 3D-printing technologies. Designing zero-emission concrete is the ultimate goal of Ye’s research.

Guang Ye is working on several projects involving the development of sustainable concrete.

- The EU Interreg project URBCON. Part of this project was the geopolymer concrete pedestrian bridge in Slaghaam, a project for the Municipality of Rotterdam.

- Ye is leading in the development of a larger car bridge made from geopolymer concrete which is planned to be built in Friesland.

- The Horizon2020 project Wool2loop. Within the project they work on the development of a binder for concrete made of glass wool.

- The EU project AshCycle. Ye is working on industry-urban symbioses revolving around the underutilized ashes to reach circular and climate neutral economy in Europe.

- The Horizon2020 project Cementigrity. A project to develop and test novel cement designs for CO2-storage.

Published: September 2023

![[Translate to English:] [Translate to English:]](https://filelist.tudelft.nl/_processed_/4/d/csm__AHK7694-%20portret_e9d1df3130.jpg)

![[Translate to English:] [Translate to English:]](https://filelist.tudelft.nl/_processed_/e/9/csm_Rita%20met%20boor%20in%20story_531bc7895a.jpg)