PGMI/PMMA double layer resit recipe

Application

PGMI: PolydiethylGlutarimide, solved in cyclopentanone (75%) and Tetrahydroferylaclohol (25%)

tone | positive |

use | double layer resist for lift-off mask |

reference | Data sheets available from Microchem |

spin coat and pre bake | First layer: PGMI, 7%, 2600 rpm 5 minutes on hotplate @ 200 0C second layer: PMMA 950 K 2% in Anisol, 6000 rpm 2 minutes on hotplate @175oC (for thicknesses < 500nm) or 30 minutes on hotplate @ 175oC (for thicknesses > 500nm) |

exposure | about 1200 µC/cm2 @ 100 kV |

development | 60 s in MIBK : IPA = 1 : 3 30 s in IPA 10 s in MF 321 15 s in Water 10 s rinse in IPA |

limitations | Due to undercut, line separation must be more than 400nm. Lift-off has to be done with PRS, acetone can not be used |

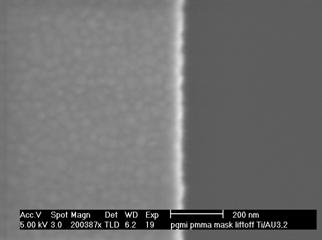

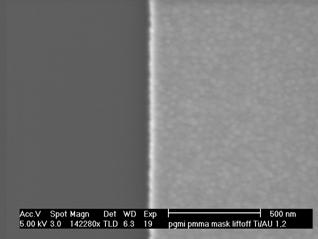

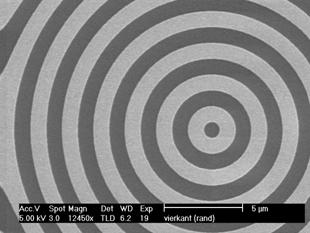

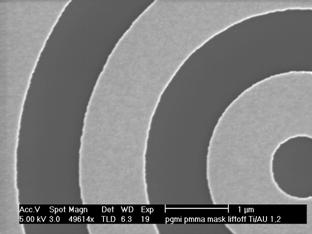

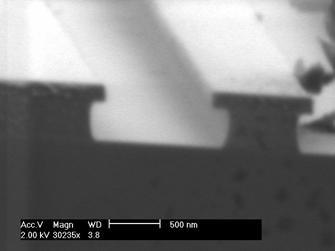

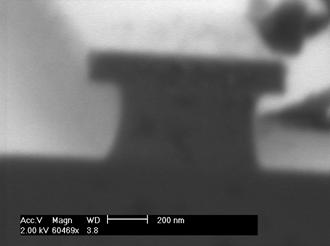

Results: SEM micrographs

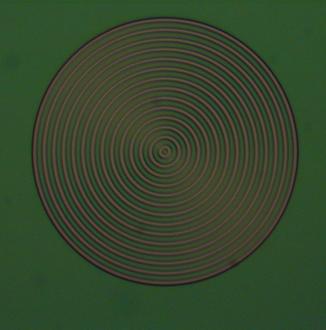

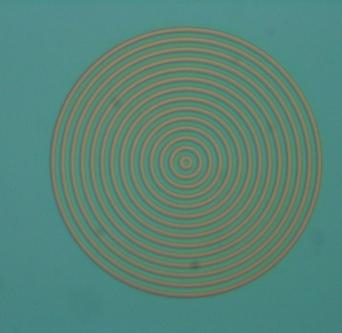

Optical microscope

After PMMA development, before PGMI development

After PGMI development

Deposition of Ti 10 nm, Au 80 nm (e-gun evaporation).

Liftoff in PRS or PRS, 80 degree C for 2hours (Lift-off not in acetone!!)

SEM inspection after lift-off