More and more greenhouses are being built worldwide due to their reliable environmental conditions; inside however, the amount of sunlight that plants can use for growth is limited. Physicist Sadiq van Overbeek from PHYSEE, a spin-off of the Radiation Science & Technology department of TU Delft, found a solution to this bottleneck: a special coating on the greenhouse that converts incoming light towards the part of the spectrum that plants use for photosynthesis. Van Overbeek: “First results show up to 10% more crops with this PAR+ coating.”

The Delft company PHYSEE, founded in 2014 by Willem Kesteloo and Ferdinand Grapperhaus, is a spin-off of the Luminescence Materials group at the department of Radiation Science & Technology (RST) and markets two core products: SENSE, which implements sensors and software to make offices more sustainable, and PAR+, a coating product for greenhouses that can now boost crop production up to 10%. Physicist Sadiq van Overbeek invented the coating:

Solution to the bottleneck of light

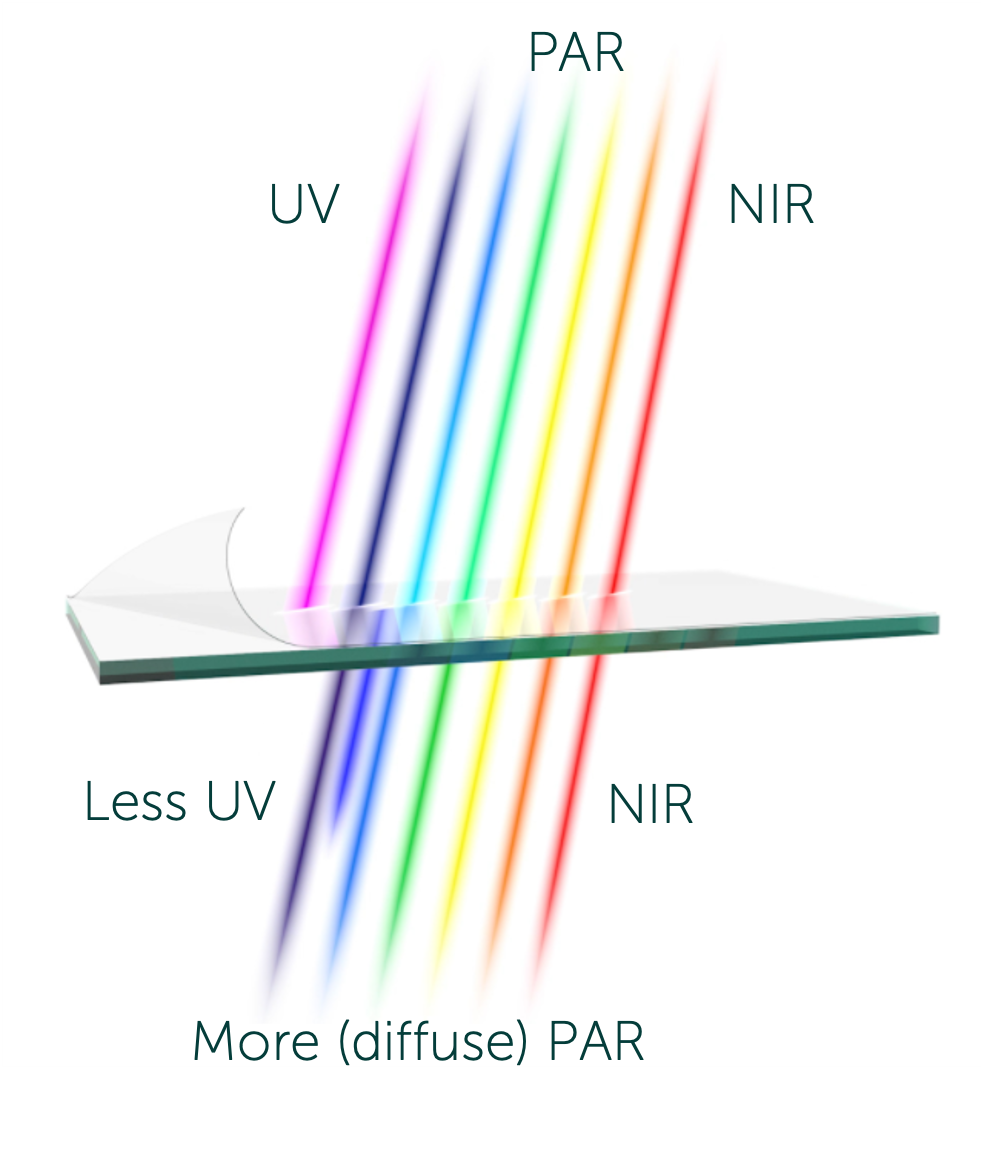

“Inside a greenhouse the amount of sunlight forms a natural bottleneck for plant growth,” Van Overbeek explains. “The plants can use only a small part of the light spectrum for photosynthesis, from 400 to 700 nanometres. This spectrum is called photosynthetic active radiation or PAR light in short. Unfiltered UV light can cause mutations in plants as well and lead to more pest insects. The PAR+ coating which we invented absorbs the UV light before it reaches the plants, and converts it into useful PAR light.”

With the coating, the PAR+ team was able to increase the number of crops inside the greenhouse by 8% to 10% compared to a seasonal coating and a situation without a coating – as a general rule, 1% more sunlight falling on crops equals 1% more crops. “We coated an area of 50 square meters of cresses with PAR+ and measured different aspects of the crop to look at the effects: colour of the crops, how the roots are growing, the length of the cresses and quantity. Our coating outperformed both control areas by far. We are now in the process of testing the coating on an area of 560 square meters.”

A better deal for agricultural companies

Agricultural companies already apply coatings in greenhouses on a yearly basis, so that the light is more evenly distributed on the crops; but the difference with the PAR+ coating is that PAR+ helps the plants gain more light overall. And there is a second advantage: “At the end of summer, the companies remove the coatings again, since they want to capture as much light as possible going towards winter”, Van Overbeek explains. “Since our coating works well all year, it doesn’t need to be removed and reapplied each year with additional installation costs. We are now working towards a coating that is durable for 8 years.”

How does the collaboration with RST take shape? “We enjoy the collaboration with the RST department because it brings us close to future talent, specifically applied physics students who have experience with luminescence, and chemistry students who have experience with coatings. At any given moment we will have two students working with us for their master thesis. We hope that we can pave the way for other start-ups to work together with RST, because we see it as a very symbiotic relationship: we write on publications and research grants together and we give these students guidance and really involve them in the company – eventually they often become our employees.”

Sharing with your competitor

The PAR+ team also works together with a wide variety of expertise in the whole agricultural chain: a company to produce the materials for the coating, another to mix these materials, yet another one to develop the glass. “We send our samples with new coatings to researchers at Wageningen University – the number one agricultural university in the world. They measure the effect of each new version of the coating.”

PHYSEE then sells the coating to greenhouse owners who give feedback about its effectiveness: “I dare say that the Dutch horticultural sector is the most innovative in the world,” says Van Overbeek on working together with the owners. “In many other industries it wouldn't make any sense to share with your neighbour and fellow competitor what product works well and what doesn’t. However, in the Netherlands this is done often. That’s great for us, because it means if our product works well, word immediately spreads and we can get a larger audience.”

More and more greenhouses

What is Van Overbeek’s ambition with this coating? “My ambition with this product is to get our research and development to a point where our coating can get the most energy and yields out of sunlight as possible, at any moment of the day. From that point on, we want to make the coating more dynamic to fit the environmental conditions in other places in the world.”

The number of greenhouses worldwide is on the rise, according to Van Overbeek and Kesteloo: “By 2050 we need to increase our food production by 70% to feed 10 billion people. With less and less land to grow on and increasing volatile weather conditions, more and more countries are building greenhouses: they offer a protected environment and in greenhouses you can increase the production of crops tenfold,” says Van Overbeek. All of these greenhouses have light as the limiting factor: “So even in Saudi Arabia our coating can contribute to faster growth of the crops.”