Mechanical Engineering students design solution for high-altitude assembly

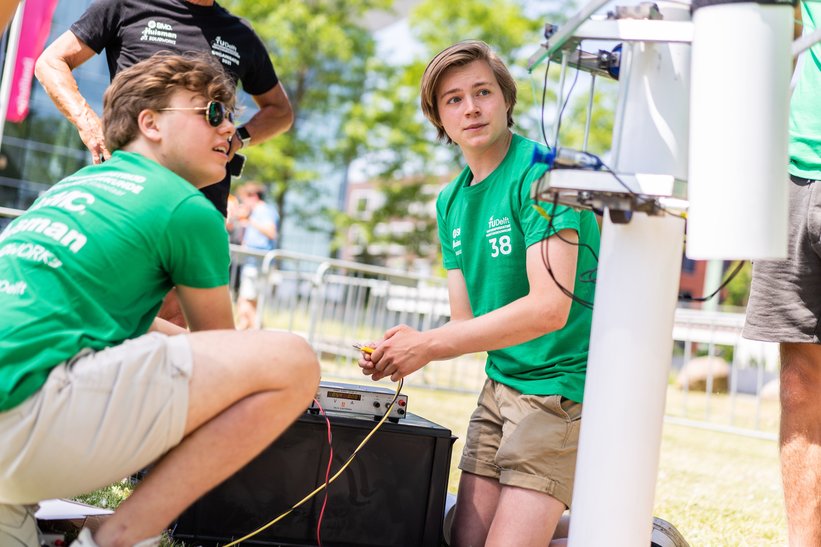

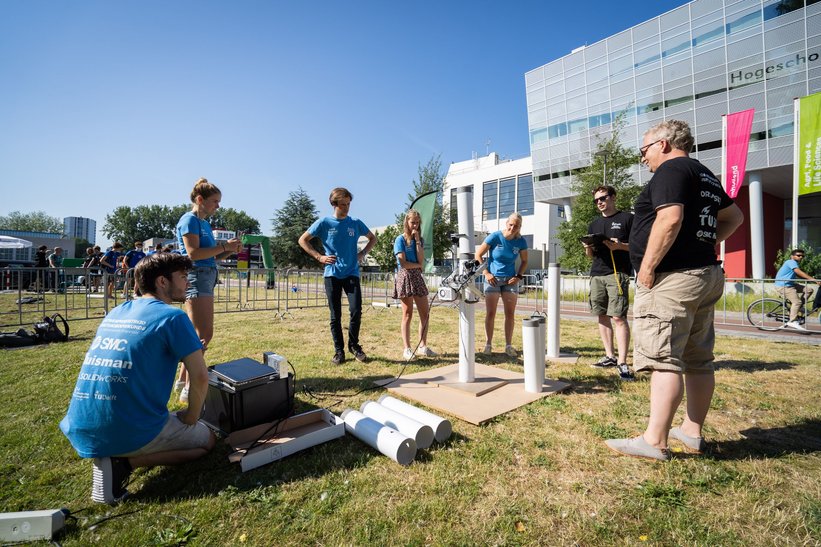

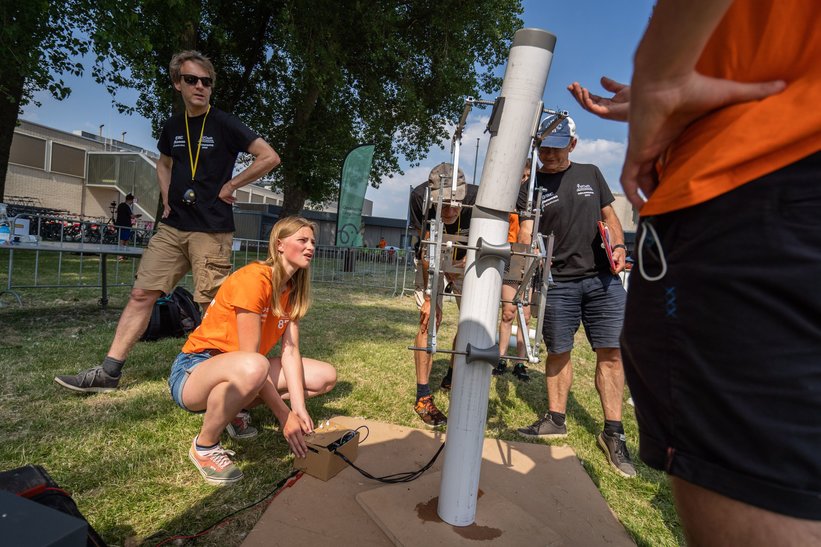

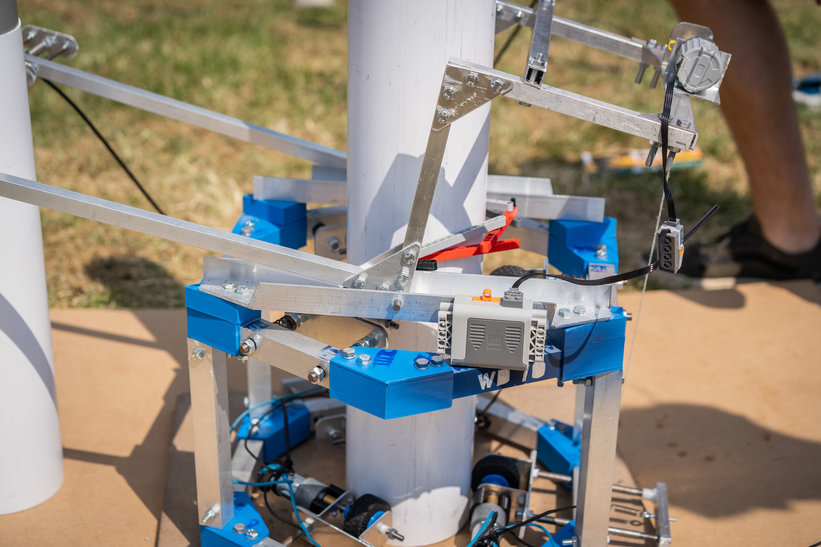

A mechanical device that can climb up a tube without assistance, carry another tube while it climbs and stack it on top of an already upright tube. Almost 600 first-year mechanical engineering students at TU Delft spent six months working on the best possible design for a ‘Climbing Stacker’, which could help to assemble increasingly large wind turbines in a more efficient way, for example. The design that performed best technically received an award during the design competition on 16 June 2021.

We have already exceeded the 100-metre length limit for wind turbine rotor blades; in the coming years, the length of rotor blades will be scaled up to 120 metres. Only scaling up the rotor blades geometrically would make them far too heavy. Every additional metre requires a lot of research and calculating. New materials, constructions and building methods are being developed for this purpose. Increasingly large cranes are needed to build these tall turbines, which is logistically complex and disproportionately expensive. As a result, turbine manufacturers are looking for other innovative ways to handle high-altitude assembly. The assignment for the 2021 design competition was based on this social issue.

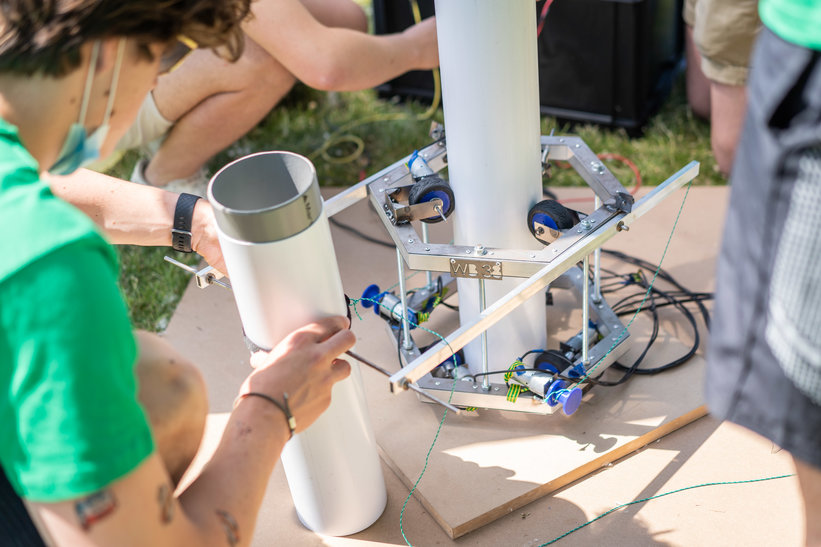

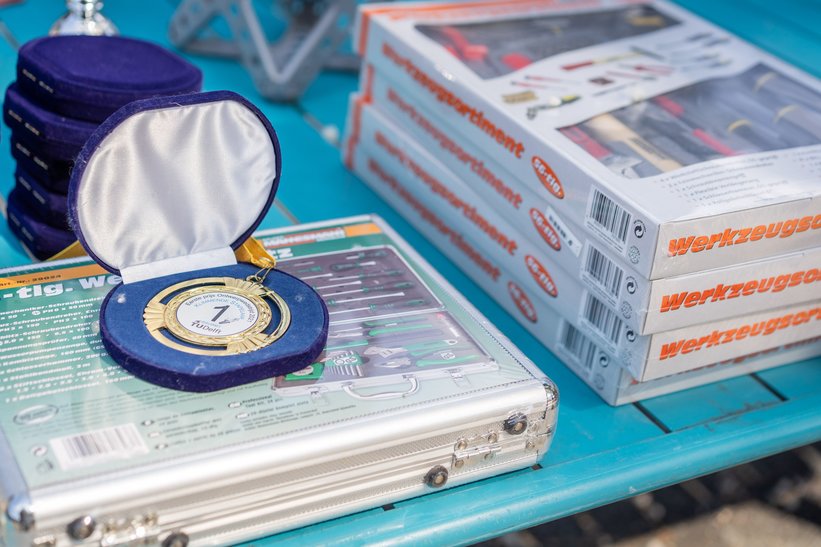

A lot goes into this kind of mechanical design. “The Climbing Stacker needs an automatic braking mechanism and a smart drive and energy source for the climbing motion,” says Regine Vroom, coordinator of the design competition. “A mechanism with actuators had to be designed to position the tube, and the balance had to be taken into account to prevent it from falling over. In addition, there were various requirements in terms of safety, materials, finishing and cost.” The performances during the competition were observed by the lecturer-judges. In the end, student team 31 delivered the best design performance, stacking three tubes in just 32 seconds. Judges from the industry – including Huisman Equipment B.V. and Design Solutions – used their own criteria to assess which designs performed best from an industry perspective.

This was a positive ending to an academic year with mostly online teaching for the first-year students, who were able to congregate in small groups on the lawn behind the faculty to showcase their design achievements. The public were unable to join them on location, but there was nevertheless enough support from interested parties who watched the competition online on a livestream. Read more about the Mechanical Engineering BSc programme’s annual design competition..