From powder to product: new TU Delft lab covers entire 3D printing process

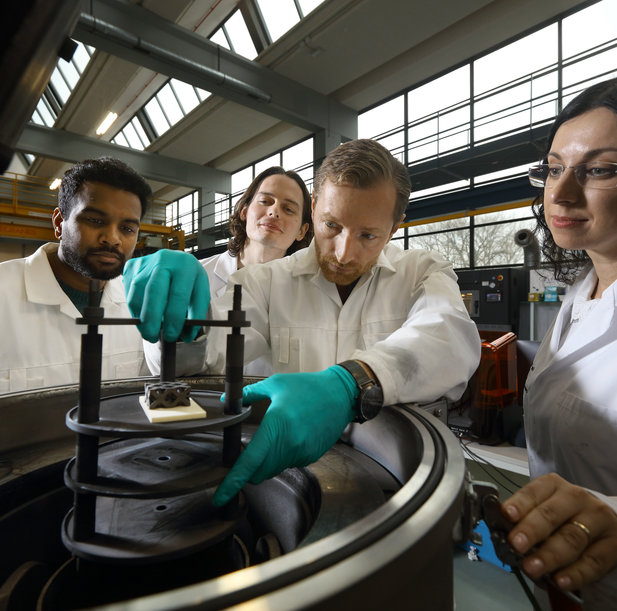

Advances in aerospace and energy transition require materials that meet ever-increasing demands. Such as extreme environments, high pressures or temperatures. In TU Delft's Materials for Additive Manufacturing lab, researchers can now explore new materials and process them into products and components for extreme conditions. This unique lab was opened on 30 November.

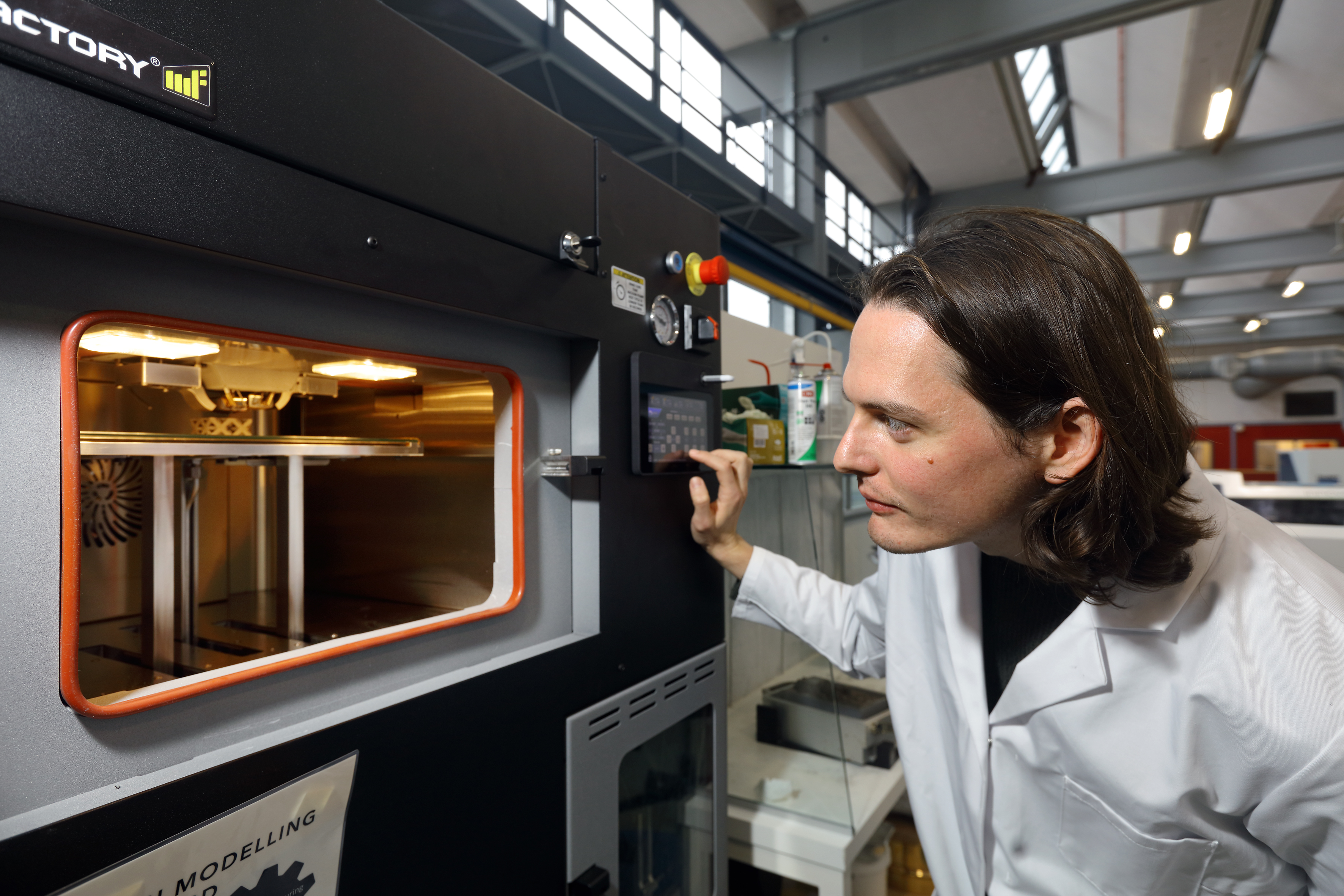

The TU Delft campus is home to more additive manufacturing, or 3D printing, labs. But this new lab is one of a kind, assures Vera Popovich, associate professor at the Faculty of Mechanical, Maritime and Material Engineering (3mE), researching materials and mechanics for extreme conditions: "Because we can now make in-house materials that 3D printers use," Popovich says. Until now, these powders were sourced from commercial parties, making the raw material a black box for researchers. "The composition and quality of raw materials are like DNA," Popovich explains. "It influences the entire production process and the final properties of the product. If we don't know the DNA in its entirety, it limits our process and design flexibility." The fact that the researchers are now able to design raw metallic and ceramic materials themselves and incorporate them into the complete additive manufacturing chain is an important milestone.

We want to use this new laboratory to investigate existing and new metallic, ceramic and composite materials, and design products with extraordinary properties on different length scales. These will ultimately bring us closer to solving important societal problems, such as the energy transition, sustainability and durability.

Vera Popovich

Building bridges

In addition, the Materials for Additive Manufacturing (MAM) lab enables the design and production of materials with higher strength and greater energy efficiency, as well as creating complex shapes, reducing the amount of material where needed or even using natural or more sustainable resources. It is a collaboration between the faculties of 3mE and Aerospace Engineering (AE). The focus of the lab is on exploring materials and developing products that can withstand extreme conditions, such as in air and space. "We see this lab as a bridge between the different disciplines of 3mE and AE and between fundamental and applied researchers," says Popovich. "This lab would enable us to dive into investigating not only new materials but also old ones from new perspective, and their advanced manufacturing”, says Yinglu Tang, assistant professor at AE.

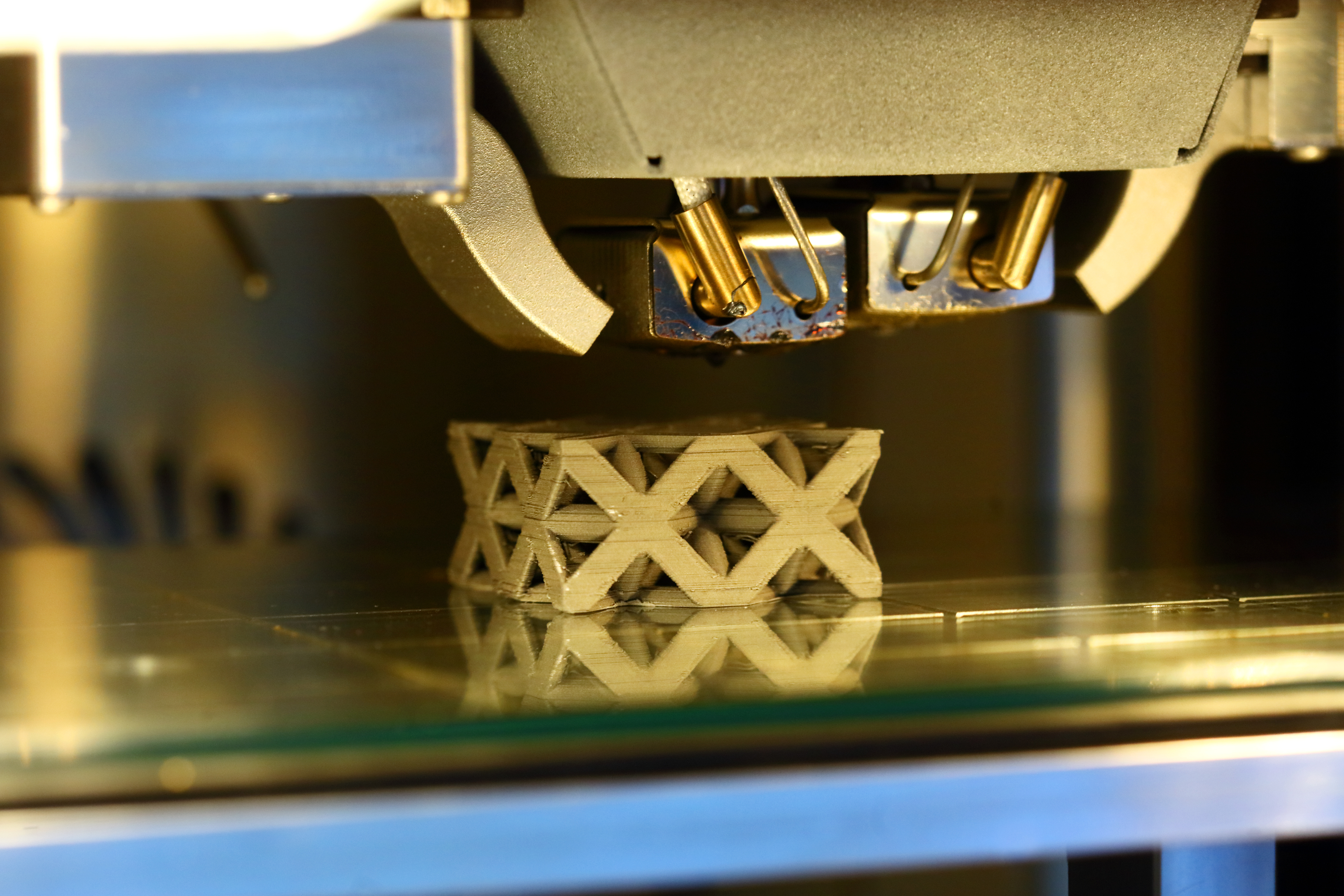

From space to chips

Collaborative research effort between 3mE and AE has already started, with the form of shared PhD candidates and master students. For instance, PhD candidate Yun-Ching Lin, is studying the high temperature oxidation resistance of ultra-high temperature ceramics (UHTC) through different porosity, shape and grain sizes. This could form the basis for new materials that meet the requirements of applications in extreme environments, such as high temperature and radiation. But the fields of application reach further than air and space. Materials master's student Adithya Keshav Mohan is investigating whether a steel component in lithography machines can be replaced by ceramic 3D-printed material. This project lays the foundation for designing more efficient components for lithography machines, potentially improving the chip manufacturing process.

Societal challenges

The goal of Popovich and colleagues is to significantly change the way 3D printing is applied, that it is no longer seen as a method to produce prototypes with, but as a real, high-quality production method, an enabler that offers enhanced or integrated functionalities. "We want to use this new laboratory to investigate existing and new metallic, ceramic and composite materials, and design products with extraordinary properties on different length scales", says Popovich. "These will ultimately bring us closer to solving important societal problems, such as the energy transition, sustainability and durability”.