Mechanical engineering at nano-scale requires clean environment

When working at the nanoscale, even a speck of dust can cause disruptions. That is why you find several clean rooms across the TU Delft Campus. In the clean room of Mechanical Engineering, researchers have the unique possibility to build mechanical structures at nanoscale, from top-down by sculpting materials and bottom-up by additive nanomanufacturing. The resulting devices find applications in a variety of fields, from biology to material science.

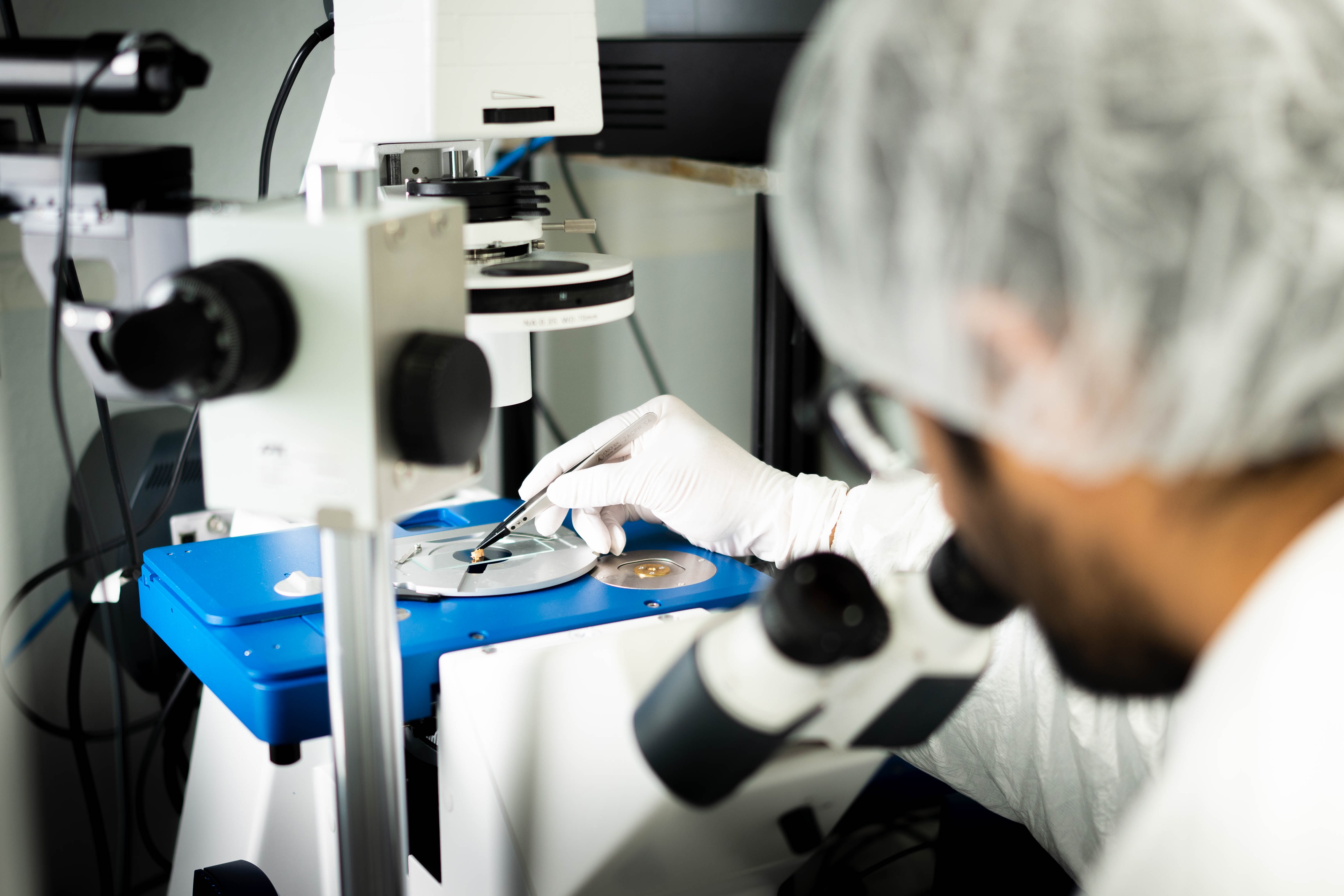

A suit, hairnet and gloves are needed to enter the cleanroom in order to protect the tiny devices from dust particles. While the cleanrooms at the Kavli Institute and Else Koi Laboratory focus on 2D lithography-based fabrication of micro and nanoscale devices, the cleanroom at the Department of Precision and Microsystems Engineering (PME) focuses on 3D fabrication of such devices, explains assistant professor Murali Ghatkesar. “The fabrication methods we use are more focused on rapid prototyping. We use high power lasers to sculpt hard materials and polymerize resins to build structures of soft materials. We even do hybrid fabrication, which means that we build a 3D nanostructure on a 2D fabricated device. Besides, our cleanroom is also used to characterize these tiny devices for their mechanical performance”, he says.

Subcellular biopsy

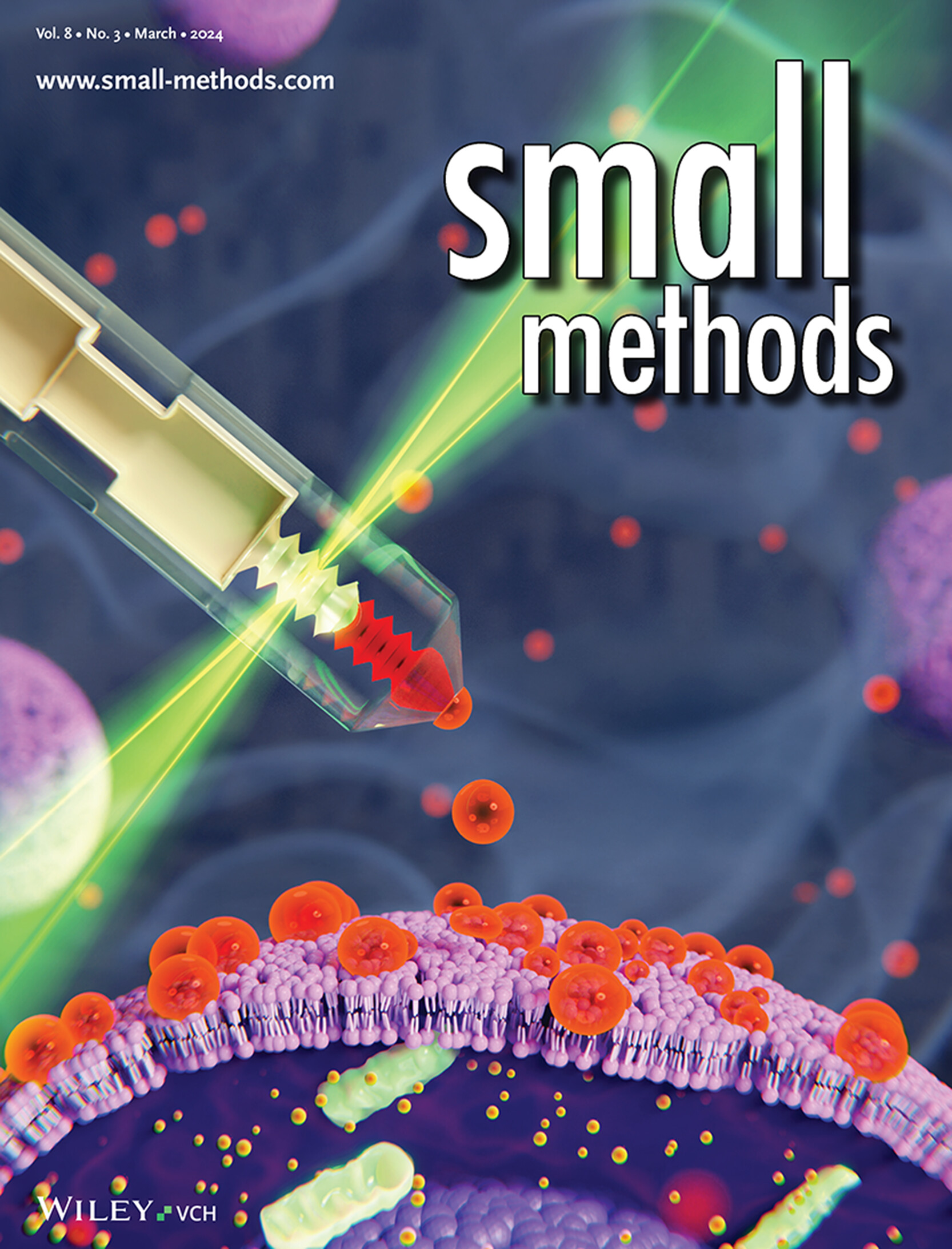

PME's clean room stands out mainly because of its nanoscale 3D fabrication and advanced characterisation facilities. "Which is unique within TU Delft," Ghatkesar says. He uses the facility to fabricate nano-devices to perform subcellular biopsy, among other things. Since most existing techniques that can be used to analyse subcellular components, such as mitochondria, require destroying the cells and meticulously separating the cellular constituents, there is a need for precise methods that can directly access the subcellular objects to unravel their role in diseases. “We 3D print a monolithic microfluidic cantilever-based device covering length scales from millimeter to nanometer, which is ready to use for experiments in just one day. It takes several weeks if I had to fabricate the same by lithography-based methods, and even then, getting some 3D features is impossible,” says Ghatkesar. “We investigate the use of such microfluidic cantilever to directly manipulate and extract subcellular components from an individual cell for further processing.”

Murali Ghatkesar

With such a device, stiffness and adhesion strength of an individual cell is also measured, which is crucial information in cancer research. “Changes in the micromechanical characteristics could provide information on whether tumour cells will metastasis or not,” Ghatkesar explains. To grasp the precision of 50 femto-litres (50 x 10-15 L) of volume that he can control with his 3D-printed device, Ghatkesar compares it to the diameter of a human hair. “Approximately 10 cells can fit across the width of a single human hair, and with our precision devices we can control a volume that is 20 times smaller than the internal volume of an individual cell.” Recently, Murali and colleagues published a new article about this in Small Methods.

From brain cancer model to graphene

The use of the cleanroom to fabricate and characterise nanostructures reach far and wide. Colleagues of Ghatkesar investigate nano-scaffolds inspired by the geometry of the brain microvasculature, which enables the researchers to better study the effect of proton therapy on aggressive brain cancer. Others use the facility to investigate the antibacterial properties of bone implants with nanopillar arrays on the surface, but also to study the unusual mechanical properties of 2D materials like graphene.

Education

Besides research, the clean room is also being used for educational purposes. Master thesis students of PME and other departments, mostly Biomechanical Engineering, Process and Control, and Delft Centre for Systems and Control, also actively use the fabrication and characterisation facilities present in the cleanroom.