New welding technology paves the way for greener aircraft

Delft-based non-profit research centre SAM XL is a global leader in developing ultrasonic welding for aircraft components, a technique that promises to spawn lighter, more sustainable aircraft.

By Bennie Mols • December 11, 2023

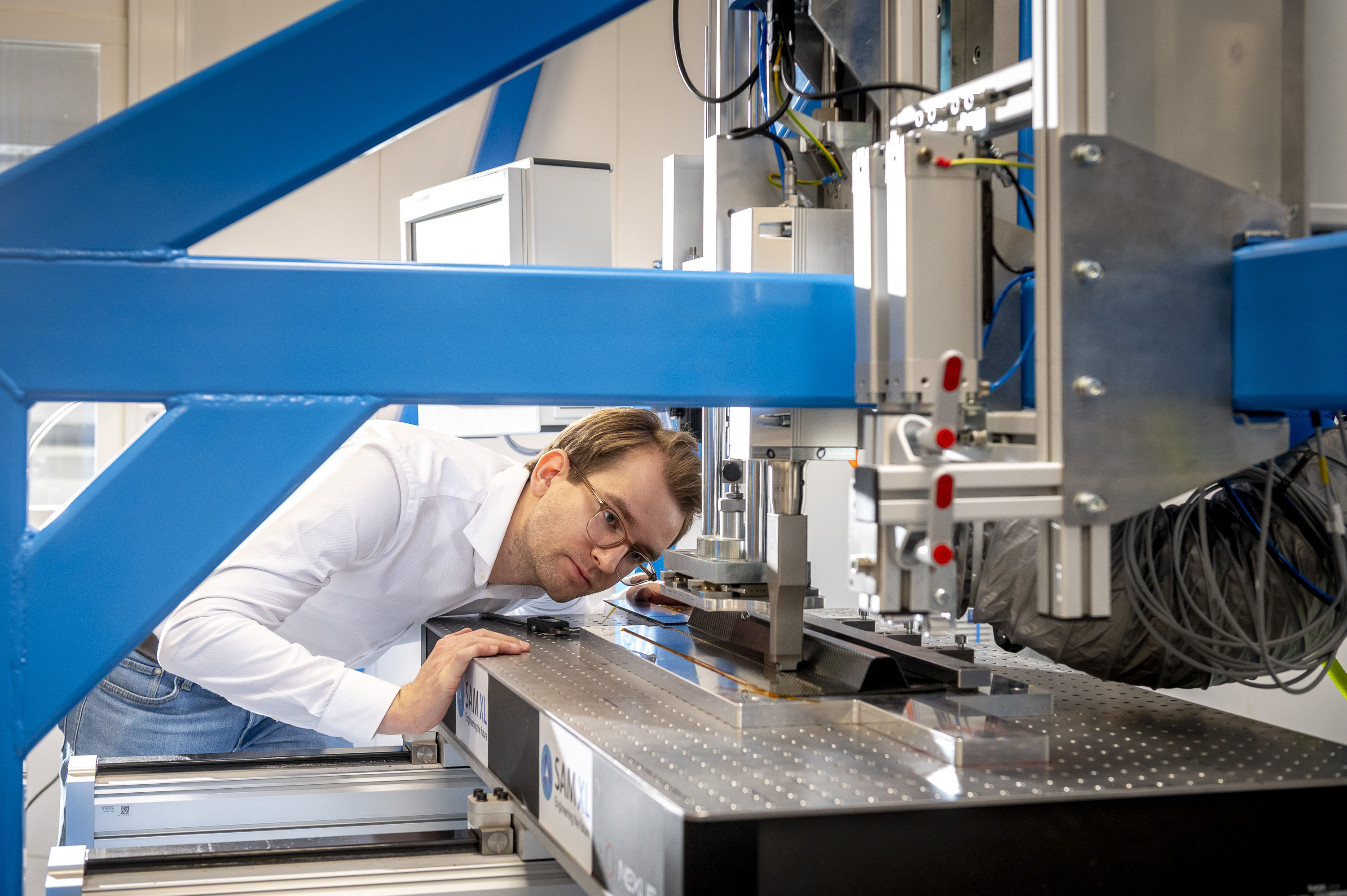

Bram Jongbloed, process engineer at SAM XL © Erno Wientjes

SAM XL's colossal research facilities already abound in small robotic arms and experimental setups, but they have recently welcomed a large, new orange robotic arm. Starting in 2024, this robot will gradually show the world the merits of ultrasonic welding in the assembly of future generations of airplanes. With this technology, SAM XL is set to make a valuable contribution to making the aviation industry as climate-neutral as possible.

For years, airplanes were made primarily from aluminium, but the relentless pursuit of weight and fuel savings has meant that this metal has lost ground to lighter, stronger composite materials made from long strands of carbon fibre. The latest generation of composites, known as fibre-reinforced thermoplastics, melt when exposed to sufficient heat and can therefore be welded together, eliminating the rivets used in today’s airplanes. Not only are the materials lighter, but you also need fewer components.

‘The biggest challenge is developing a welding technique that lets us consistently produce long, high-quality welds on complex surfaces at high speeds’, says SAM XL process engineer Bram Jongbloed. ‘And we happen to have found a solution to that very challenge. We have developed an ultrasonic welding technique that has already been proven to work in various research projects.’

Fieldlab ID

| Fieldlab | SAM XL is short for Smart Advanced Manufacturing using extra-large (XL) robotics. The research centre was established as a non-profit foundation under the aegis of TU Delft. |

| What happens there? | The automation of aerospace production and inspection techniques, bridging the gap between fundamental research and industry applications. |

| Headquarters | TU Delft Campus - building 137, Rotterdamseweg 382C, 2629 HG Delft |

| Year founded | 2018 |

| Number of employees | 19 |

| Partners | Airbus, TNO, NLR, Fokker GKN Aerospace, GTM Advanced Structures, Airborne, KVE, CEAD, Suzlon and more. |

Automated continuous ultrasonic bench welder with patented sonotrode design © Erno Wientjes

A daunting challenge

While ultrasonic welding has been used to weld plastics for decades, thermoplastic composites were a much more daunting challenge, prompting SAM XL to develop its own proprietary software and hardware. Jongbloed: ‘Our ultrasonic welding technology uses a sonotrode, a kind of hammer, that vibrates at a frequency of 20,000 Hz as it presses down on the weld. This creates so much friction on the interface and the thermoplastic itself that the material melts, but because you only melt a small section of the material, it’s also highly efficient.’

SAM XL has demonstrated the underlying concept of the continuous ultrasonic welding process by welding a few dozen cm stretch on a straight surface and has even carried out robotic spot welding on a full-size fuselage panel of an Airbus aircraft. Jongbloed: ‘When we welded that 8x4m panel, we became the first to apply ultrasonic spot welding on an aircraft component made entirely from thermoplastics.’

With the recently installed robotic arm, SAM XL intends to demonstrate that it can also perform welds spanning several metres, before taking on the challenge of curved surfaces. Jongbloed: ‘We are currently developing a new software framework with so-called zero-programming, which will give the robotic arm the intelligence it needs to scan an object, build a digital model and generate optimal weld routes regardless of the shape.’

Bram’s focus is to develop and industrialise innovative manufacturing techniques © Erno Wientjes

Testing the robot’s motion in anticipation of the welding process © Erno Wientjes

Bridging the gap

In practice, there is often a large gap between fundamental scientific research and real-life applications in the aviation industry. SAM XL was created to bridge that gap. In the coming years, SAM XL aims to bring ultrasonic welding technology closer to commercial applicability, and aircraft manufacturer Airbus is the key partner in this.

Jongbloed: ‘Airbus is keen to develop ultrasonic welding and we’re the world leader in it. We frequently consult with people from Airbus and often have them round to showcase what we are doing. Airbus wants to be able to produce as many as 100 A320 aircraft a month, and if they decided to use thermoplastic composites, they would need assembly techniques that are up to the task. We have now drawn up a roadmap with the goal of having ultrasonic welding commercialised by a manufacturer like Airbus by around 2035.’

SAM XL is also particularly interested in supporting the Dutch manufacturing industry and has seen interest in its technology skyrocket. It has recently started looking into ways to harness ultrasonic welding for hydrogen tanks, which will play a key role in the energy transition.

![[Translate to English:] [Translate to English:]](https://filelist.tudelft.nl/_processed_/1/b/csm_Breda%20-%20151%20of%20154_scaled_74fd0bc3b8.jpg)