Rapid innovation is needed to reach the 2050 sustainability goals for the aviation sector. But rather than a lack of ideas, or the effort needed to bring these to fruition, the main bottleneck in reaching these goals are the existing, very lengthy certification procedures. Three TU Delft professors therefore propose a radically different approach towards certification in aviation.

“When it comes to innovation in aviation, new materials play a pivotal role,” says René Alderliesten, associate professor in the Structural Integrity & Components group at the faculty of Aerospace Engineering. “They are needed to support new aerodynamic airplane designs such as blended-wing bodies, for safe and lightweight onboard storage of alternative fuels such as hydrogen, and for reducing waste at the end of life of airplanes.” History, however, tells a rather unsettling story: it took nearly three decades to advance both carbon fibre composites and fibre metal laminates from first tests in the laboratory to their introduction in aerospace. “Even if we would have the perfect model of a sustainable airplane on paper right now, we probably wouldn’t be able to fly it by 2050,” says Nathan Eskue, associate professor in the same group. “Certification is the critical path, and it needs to be sped up.”

If you can’t certify it, you can’t fly it

Testing pyramid

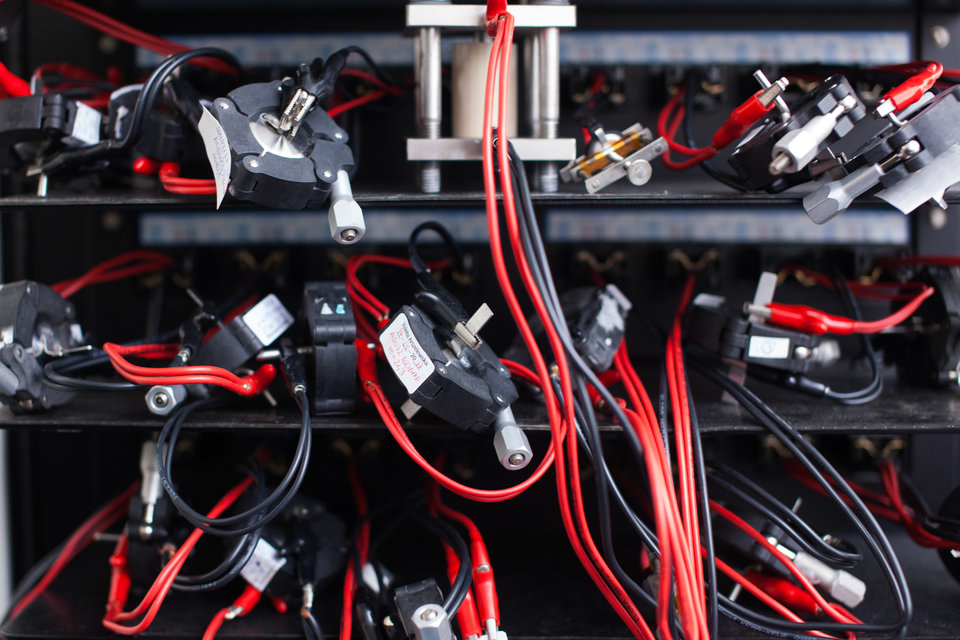

Currently, new materials must undergo myriad tests – ranging from (very many) general material properties tests to (a lot of) sub-component tests to (a few) major integrated tests on board actual airplanes. It is this testing pyramid that forms the basis of air travel safety. Many of these tests are destructive tests in which samples are exposed to stresses until they break. This helps in building prediction models that are used to prove that any future batch of components, when integrated into the whole, will hold up to specifications. “The pyramid is a tried and trusted approach, but materials science is advancing very rapidly,” says John-Alan Pascoe, who is assistant professor in the same group. “Nowadays, we can 3D-print components, we can optimise the location and orientation of advanced fibres, and we can implement architected microstructures. Using these approaches would mean that we must qualify hundreds, if not thousands, of new materials for each innovative component we want to use in an airplane. If you can’t certify it, you can’t fly it, so this very much limits our design freedom.”

Three pillars of smart certification

The three professors have made it their group mission to develop a smart certification approach that will reduce the time to certification with at least ten years. Alderliesten: “We want to make all that destructive testing prior to prediction obsolete and get to the point where individual components are certified once they have been built.” The three pillars to their solution are physics, process monitoring and simulation-based acceptance. With Alderliesten and Pascoe experts in materials fatigue and structural integrity, and Eskue expert in process monitoring and artificial intelligence (AI), they have all bases covered.

A tight fit

“By delving deeply into physics, our aim is to fully understand how core material properties translate into mechanical properties under stress, such as stretching, bending and crack formation,” Pascoe says. “And by employing sensors both during and after fabrication, we can closely monitor and control the state of the parts we build – their microstructure and any minor defects they may contain.” Then, AI is key in answering whether these defects are acceptable or not. The AI models will take the physics and sensor data to predict, if a component were to be tested, whether it would meet requirements or not. “There is a lot of cross-fertilisation between these three pillars,” Eskue says. “We will use the physics and sensor data to help build the AI models and to help ensure that these models are explainable. But AI can also help uncover missing pieces in the underlying physics theories and in determining what kind of sensors still need to be developed.”

Equivalent level of safety

“Our proposal sounds logical, but the implication is that it requires a different type of research and science,” Alderliesten says. “We have worked out the top level of smart certification, but there are still thousands of challenges we need to address.” Perhaps the toughest nut to crack is industry acceptance, as anything new in the aviation sector has to be proven to provide at least an ‘equivalent level of safety’. Pascoe: “When it comes to metal planes, we have fifty to a hundred years of experience, and loads of testing data on how metals behave. When introducing new materials, we need to prove that these are just as safe.” The same holds for their smart certification approach, which they must prove to be at least as safe as the testing pyramid. It is why they closely collaborate with industry – materials, components, and aircraft manufacturers. Alderliesten: “We let them try out our approach in their own production process so they can experience first-hand that it guarantees safety while at the same time being both a time saver and cost saver.”

The more testing we can eliminate safely, the more quickly we can get to new, sustainable aircraft

On to sustainable aircraft

Right now, the researchers are trying to build a simulation-based acceptance model for several manufacturing processes. They then aim to generalise their findings such that their approach can be more readily adopted for any new material and production process. There will certainly be intermediate milestones, celebrated passionately by the researchers, but it may take up to a decade for society to start experiencing the benefits of their efforts. Eskue: “Our path towards success will feel agonisingly slow for a long time, but once it takes off, it will move fast. And with testing being non-scalable, even the small steps are worthwhile. The more testing we can eliminate safely, the more quickly we can get to new, sustainable aircraft.”