Research Activities

Computational Design & Mechanics

? Modeling and simulation

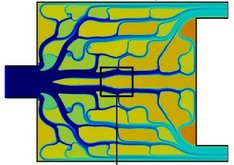

Efficient and accurate evaluation of the performance of a design is an essential aspect of any computational design process. Next to using conventional finite element, finite volume and finite difference methods, we also develop advanced and immersed finite element techniques that show superior convergence rates and avoid meshing complexity, particular for complex and evolving geometries. We also perform research on efficient simulation of manufacturing processes, in relation to the Design for Manufacturing theme listed below.

-

Below is a selection of computational models we have developed, typically in a design setting:

Fluid-structure interaction model for flexible flapping wings (e.g. insect wings)

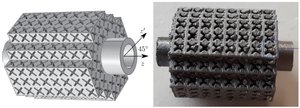

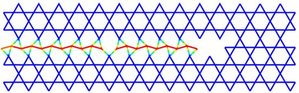

Effect of imperfections in lattice materials

-

We develop enriched finite element methods that offer superior accuracy. Moreover, by decoupling the part geometry from the mesh itself, our methods remove the meshing challenges of complex geometries.

Examples include:

DE-FEM: Discontinuity-Enriched Finite Element Method

-

To avoid defects and fully utilize AM's potential, process simulation is essential. We focus on models suited for part-scale simulation and gradient-based, AM-focused design optimization.

A selection of models we develop:

AM process- induced microstructure prediction

Efficient WAAM process modeling

Fast detection of overheating in LPBF

Fast computation of AM part distortion

? Design Optimization

In most of our computational design methods, mathematical optimization techniques are used to drive the design to increased functionality. Typically this involves gradient-based algorithms, combined with adjoint sensitivity analysis. In topology optimization, this enables us to generate designs that push the boundaries of resolution and complexity. For complex, integrated design problems we also study hybrid approaches, consisting of a mix of engineering insight, fundamental principles and numerical techniques. We also explore the use of artificial intelligence / machine learning techniques to generate designs even faster or with better performance than through an optimization-based process.

-

When functionality depends on geometry, we can optimize it!

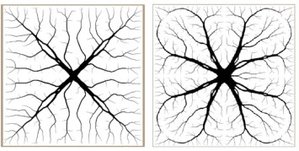

We develop new topology optimization techniques for a wide range of design problems. Below a few examples are listed:

Food eating experience (choclate)

-

By integrated design we mean the simultaneous consideration of multiple interlinked design aspects, as opposed to sequential or decoupled design approaches.

Examples:

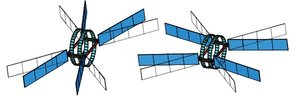

Flapping wing micro air vehicle

Controller-structure co-design

-

Ensuring that optimized designs are robust against variations in uncertain parameters. Examples:

Robust distortion control in additive manufacturing

-

We explore how to best integrate the power of machine learning into computational design.

Examples:

Autoencoder-enabled global optimization

Reparameterization in topology optimization

? Design for Manufacturing

Manufacturability is an essential aspect of design functionality. Recognizing this, we develop methods to incorporate the requirements of specific manufacturing processes in our computational design procedures. In particular the rapidly developing additive manufacturing (AM) technologies are of great interest to realize new design concepts, as geometric complexity is no longer an important cost driver. We consider both geometric and process-physics-based design criteria in our computational design methods, that can include complex transient AM process simulations. Furthermore, the reliability and sustainability of manufacturing processes is related to both design and process parameters, and we also work on optimizing these.

-

Examples:

Efficient AM process simulation

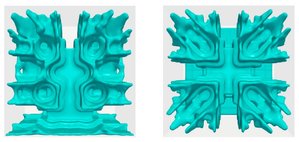

Design for AM: Overhang control 1, 2, enclosed void control

-

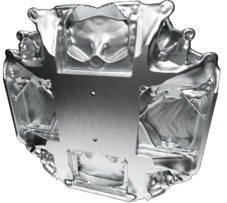

Many parts need to be clean, e.g. in the food or medical industry, or in cleanroom equipment. We develop topology optimization procedures that are guaranteed to generate cleanable designs.

Examples: drainability, jettability

-

More to come!

? Applications

Our main focus is on design challenges where mechanical aspects play a central role. These include compliant mechanisms, pressure-actuated soft robots, and also wave propagation, mechanical metamaterials and dynamic structures. But this is not our sole focus: we also develop computational design methods for thermal management, solar cell electrode design, flapping wing micro-air vehicles, heat exchangers, mechatronic systems, and more. In fact, every device whose functionality depends on its geometry, is a potential candidate for further optimization by our methods. Interested? Contact us!