Safety in Chemical Clusters

2022

The Safety & Security Science group is conducting two studies commissioned by the Dutch Ministry of Infrastructure and Water Management with the aim of creating sustainable cooperation within (petro)chemical clusters (i.e. multiple (petro)chemical companies geographically located close to each other) in the field of (external) safety.

Study 1. A cluster-based ranking of safety measures

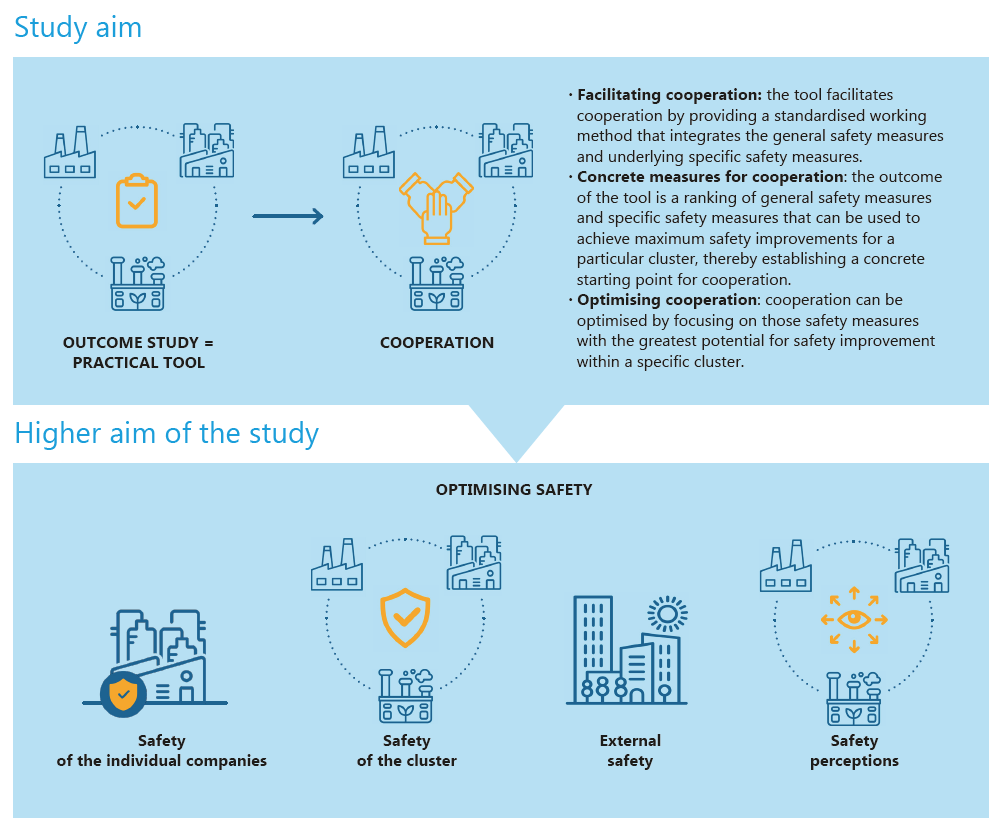

This study aims to facilitate and optimise cooperation between clustered companies and to suggest concrete measures they can take. A practical tool has been developed for this purpose. A cluster or subcluster of (petro)chemical companies can use the tool together to establish substantiated and optimum cooperation measures for managing their joint risks and increasing the safety of the cluster as a whole.

The practical tool (in the form of an Excel file) encompasses various general safety measures and more specific safety measures associated with them. These are measures that companies can take together to manage and control their joint risks. In the tool, these general safety measures have been further specified in the form of various specific safety measures. The (sub)cluster of companies using the tool will jointly give a score for the current performance (step 1) and feasibility (step 2) of all specific safety measures. In step 1, the companies give a score for their current performance, ranging from optimal to suboptimal performance (or the absence of cooperation) for the relevant specific safety measure. In step 2, the companies give a score for the feasibility of the specific safety measures. Based on a range of criteria (including risk reduction potential, costs, sensitivity to competition and the influence of the policy of the (parent) company), the companies make an assessment of the feasibility of the specific safety measures.

These specific safety measures are then automatically ranked by the underlying algorithm based on the potential safety improvements that can be achieved with them. The outcome is a prioritisation of safety measures, whereby the highest ranked safety measures will deliver the most safety improvements for a particular cluster. By including the current performance and feasibility, the ranking takes account of existing safety measures (that may have become institutionalised) and the specific context of a particular cluster.

The tool is unique in its focus on a joint approach. The prioritisation of the safety measures will make it possible to determine a substantiated and optimal way for (sub)clusters to take concerted action in achieving safety improvements with regard to joint risks. The tool can be seen as a springboard for raising levels of safety across the cluster, with the result of the tool serving as the starting point for the (further) development of concrete specific safety measures.

The tool focuses on addressing joint risks, thereby optimising safety across the whole cluster. It will also optimise external safety, since the entire area in which the clustered companies operate will become safer if their joint risks are controlled more effectively.

Study 2. Collaboration on Safety – Instrument (COSI)

This project aims to answer the question of how cross-plant safety can be improved in a general way, including the prevention of domino effects, as is requested by Article 9 of the European Seveso III legislation (Article 8 of the Dutch BRZO legislation). The research is aimed at producing knowledge to this end, and an approach and instrument (that can be used on a voluntary basis) for those companies situated in the same geographical area, and wishing to improve safety together by learning from each other. The following are the specific research questions (RQ) that this project investigates:

- RQ1: What is the current state of collaboration in (petro)chemical industrial parks, and what are the main drivers and impediments to cross-company collaboration?

- RQ2: How can cross-plant safety, and more specifically also domino effects, be effectively analyzed and managed? (development of an approach and a tool involving multiple plants to investigate and manage domino effects between them)

With the above questions answered, this project will develop a practical approach and instrument that guides (petro)chemical plants to collaborate, to learn from each other, and to analyze and manage cross-plant safety, including the prevention of (external) cross-plant domino effects.