Corrosion Technology and Electrochemistry

The ultimate research mission of CTE is to gain fundamental knowledge of local corrosion processes and promote education and best practices in corrosion control for the socio-economic benefit of society, preservation of resources and protection of the environment.

There are two main research lines. The first focuses on studying the relation between the microstructure of metals and corrosion properties. The second research line focuses on the micro electrochemical characterisation of materials for diverse applications such as energy storage, art heritage and biomaterials. The application of high-resolution electrochemical methods (based on micro- and nano-sensors) connects both research lines.

Research

The ultimate research mission of CTE is to gain fundamental knowledge of local corrosion processes and promote education and best practices in corrosion control for the socio-economic benefit of society, preservation of resources and protection of the environment.

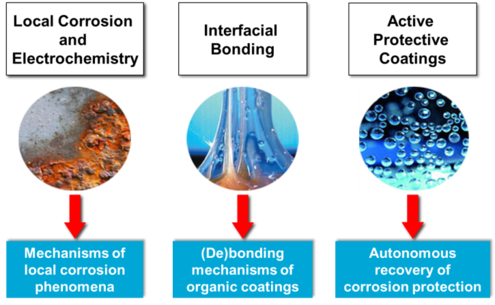

To this aim, CTE focuses its expertise on the following key research areas:- Local electrochemical analysis of corrosion mechanisms - Interfacial bonding of organic coatings and adhesives on metal (oxide) surfaces- Multifunctional and eco-friendly corrosion inhibitors and evaluation of smart coatings

A full, detailed and high level understanding of local corrosion phenomena, interfacial bonding and corrosion inhibition is only to be gained by the (in-situ) application of local electrochemical and surface analysis techniques. Continuous in-house development and (in-situ) application of these micro- and nanoscale electrochemical and advanced surface analysis techniques is crucial.

In general, the design of metal alloys is primarily based on controlling the mechanical properties by the adequate grain size, dislocation density, phase fractions and size distributions of strengthening precipitates. Corrosion performance is usually only considered in the final product at the latest stage.

This is because the microstructure design of strength is possible based on established and well-known quantitative relations between microstructure and mechanical behaviour. However, the relations between microstructure and corrosion behaviour are still largely unrevealed. This research line focuses on helping to understand why a particular metal is susceptible to corrosion attack and the relation with its microstructure. The main ambition is to understand and quantify the correlation between (localised) corrosion and microstructural features such as grain size distribution, phase composition, inclusions and intermetallics distribution.

Advanced electrochemical techniques are applied with sub-micrometre range resolution to obtain a direct correlation between microstructural features and corrosion properties. New experimental routes are implemented and explored to provide more understanding of the corrosion failure of metal alloys (eg. steel, aluminium, titanium), as well as the triggering factor(s) involved in its initiation. In this research area, the synergy between different disciplines is required: metallurgy, surface analysis and corrosion-electrochemistry.

Highlighted publications:

- Properties of Passive Films Formed on Ferrite-Martensite and Ferrite-Pearlite Steel Microstructures (2021) https://doi.org/10.3390/met11040594

- Effect of microstructural defects on passive layer properties of interstitial free (IF) ferritic steels in alkaline environment (2021) https://doi.org/10.1016/j.corsci.2021.109271

- A closer look at constituent induced localised corrosion in Al-Cu-Mg alloys (2016) https://doi.org/10.1016/j.corsci.2016.10.018

- Simulated and measured response of oxygen SECM-measurements in presence of a corrosion process (2014) https://doi.org/10.1016/j.electacta.2014.09.010

- Scanning electrochemical microscopy to study the effect of crystallographic orientation on the electrochemical activity of pure copper (2014) https://doi.org/10.1016/j.electacta.2013.11.048

The focus is investigating materials in a broader range of applications of relevance for society and industry where electrochemical processes play an essential role. For this purpose, we expand the application of micro-electrochemical approaches for interfacial processes found in research areas such as electro-catalysis, corrosion protection methods, and art restoration and conservation. My team has expertise in localised electrochemical techniques such as Scanning Electrochemical Microscope (SECM), Scanning Vibrating Electrode Technique (SVET), electrochemical micro-capillary cell and Kelvin-probe Atomic Force Microscope (SKPFM).

Highlighted publications:

- Molybdate as corrosion inhibitor for hot dip galvanised steel scribed to the substrate: A study based on global and localised electrochemical approaches (2020) https://doi.org/10.1016/j.corsci.2020.108893

- Self-healing epoxy nanocomposite coatings based on dual-encapsulation of nano-carbon hollow spheres with film-forming resin and curing agent (2019) https://doi.org/10.1016/j.compositesb.2019.107087

- Mechanism of passive layer formation on AA2024-T3 from alkaline lithium carbonate solutions in the presence of sodium chloride (2018) https://doi.org/10.1149/2.1011802jes

- Electrochemical techniques for the study of self-healing coatings (2016) https://doi.org/10.1007/978-94-017-7540-3_9

- A combined redox-competition and negative-feedback SECM study of self-healing anticorrosive coatings (2011) https://doi.org/10.1016/j.electacta.2011.03.081

Facilities

- AFM - Dimension Edge Scanning Probe Microscope

- SKP - Scanning Kelvin Probe

- VCM 600 STANDARD Vacuum Thermal Evaporator

- Theta Lite Optical Tensiometer

- Adhesion meter

- SECM Scanning electrochemical microscopy

- Potentiostat Bio-logic

- CompactStat potentiostat

- Potentiostat Autolab PGSTAT 12

- Potentiostat Autolab PGSTAT 30

- Radiometer Copenhagen CDM80 Conductivity Meter

- Ecocell 55 Drying oven

- Solartron 1286/1287 & Solartron 1250/1255 Electrochemical Impedance Analyzer

- Scanning Vibrating Electrode Technique

- SPS Spin 150 Spincoater

- Thermo Nicolet Nexus Fourier-Transform Infrared Spectrofotometer