Preventing costly measuring errors in the OR with sensor technology

How is it that carpenters have access to more sophisticated measuring equipment than surgeons have for measuring orthopedic screws used in bone fractures? Delft-based Slam Orthopedic is hard at work to make up ground. Two engineers, a consultant and a trauma surgeon are working with the Reinier de Graaf Hospital to develop advanced sensor technology that can greatly improve patient care.

By Jochen Meischke • March 11, 2024

The idea to start a business first pops up at an unusual time. Just Schornagel, co-founder of Delft-based start-up Slam Orthopedic, finds himself in a ski lift when good friend Job Komen mentions a trauma surgeon facing an interesting problem. He tells Schornagel that, on average, a Dutch person will break a bone twice in their life, and that trauma injuries are the leading cause of death among under 45s. What’s more, Dutch hospitals are inundated year after year with huge numbers of bone fractures that need to be treated.

The major consequences of measuring errors

Surgery is preferred over plaster casts, as it easier on patients’ joints and means that bones heal better. In surgery, bone screws are used to hold the damaged or broken bone together, And that’s where the challenge lies for surgeons, Schornagel is told on the ski lift.

Bones are hollow, so orthopedic screws have to be exactly the right length. Too short and you’re left with a loose screw. Too long and the screw will stick out, damaging surrounding joints and tendons. In an average procedure, surgeons use about eight screws for every bone, but to measure them, they have to rely on calipers invented in the 1940s.

And there’s the rub. The calipers are hardly ideal for today’s minimally invasive approach to surgery, characterised by tiny incisions. As a result, snags involving the calipers are common, doing significant damage.

After the procedure, surgeons evaluate the screws on X-rays and replace any screws that are not seated properly. Apart from being time-consuming, it also produces a lot of medical waste, especially now that the costly screws can no longer be sterilised and reused. Even minor measuring errors can have major ramifications, causing patient discomfort, swallowing up precious OR time and producing large amounts of expensive waste.

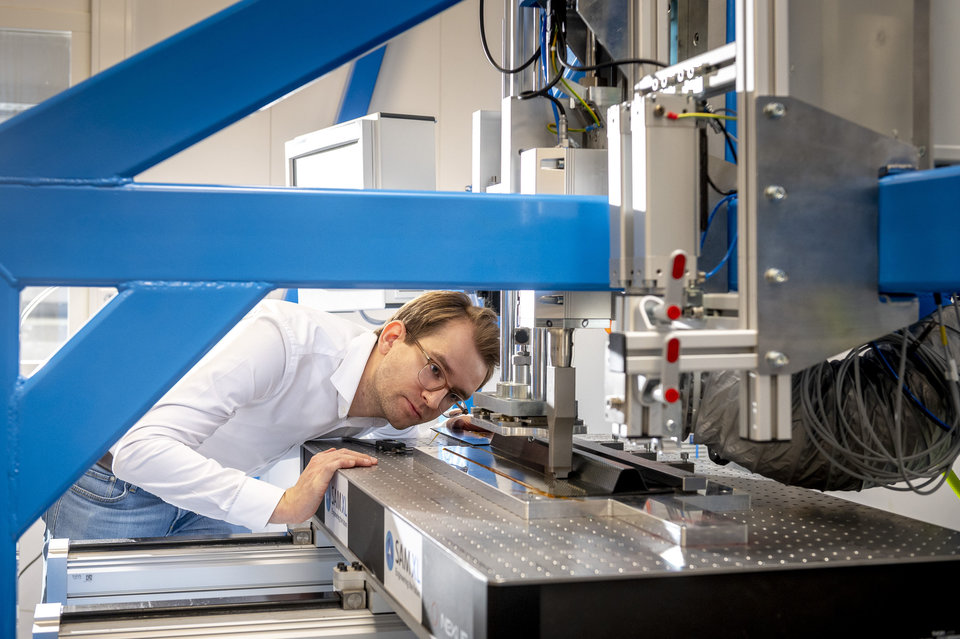

ADEPTH, Slam Orthopedic's unique sensor, was specifically designed to be compatible with existing drills © Slam Orthopedic

Tinkering in the attic

With almost 9% of patients undergoing surgery for a bone fracture developing complications, repeat surgeries are a common problem. Aided by trauma surgeon Bas de Hartog and fellow engineer Bart Kölling, Schornagel and Komen set out to find a solution. For a long time, the team had to work weekends, plugging away in the attic.

Schornagel will never forget the eureka moment, when De Hartog pointed out that their success hinged on automating the measuring process. The average surgeon, after all, does not particularly enjoy painstakingly measuring each and every screw.

Following this lighting bolt of inspiration, the team decides to take a page from the book of their competitors, who integrated measuring sensors in expensive, long-lasting drills. Ultimately, the team doubles down on using a sensor to replace the traditional caliper and a laser to accurately measure screw length. The sensors were specifically designed to be compatible with existing drills, saving hospitals from having to purchase new equipment. ADEPTH was born.

© Slam Orthopedic

From the attic to the hospital

To continue developing their technology into a product, the team opts to found a startup, before ending up at YES!Delft’s Validation Lab. Expanding their perspective, the team plunges into customer research by talking to surgeons, assistants and hospital managers. The rules and regulations for medical innovations are particularly strict and complicated, Schornagel begins: “The road from idea to practice is long and fraught with obstacles.”

For Slam Orthopedic, it all begins with studying plastic artificial bones, followed by a study in the anatomy lab, after which the time is ripe for further research with surgeons and real patients. And then there’s the hurdle of getting your product into hospitals.

Surgeons are suspicious of modern technology, which is often unceremoniously dumped onto their laps without proper research first, feeding the conservatism of healthcare staff and their reluctance to change their practices. That being said, Schornagel counters, it would be a shame if modern, available technology never reached the OR. “There is something fundamentally odd about carpenters using state-of-the-art lasers for extremely precise measurements while surgeons still use old-fashioned calipers.”

Through the Validation Lab, the team is put in touch with Daphne Wijffels from the Reinier de Graaf hospital. After a successful pitch at the Innovation Platform, the two decide to join forces. “We must have drilled hundreds of holes in practice bones”, Schornagel recalls. “Everything was meticulously measured and remeasured, after which we wrote a whitepaper describing the accuracy of the sensor.”

Innovations

Partnering with a hospital proved to be a tremendous asset for Slam Orthopedic; Hospitals are home to many many different specialist verticals, from the OR to the IT department, and the Innovation Platform opens up the door for innovations throughout the hospital. Slam Orthopedic already had the luxury of having a surgeon on board, but more input from the OR proved extremely valuable. Schornagel: "the input of the surgeons from the Reinier de Graaf hospital let us paint an even more detailed picture of specialisms and practices."

Even though the Reinier de Graaf hospital has embraced innovation, the healthcare sector in general still has a long way to go. Moreover, due to strict regulations, the road from healthcare innovation to practice is arduous and expensive, with strict requirements for research. Medtech start-ups, more so than start-ups in other sectors, have great difficulty in securing funding as a result.

Conversely, slow or absent innovation also costs society a lot of money. However, regulators are never punished for slowing innovation, but they are for allowing an unsafe product to enter the market. The same goes for surgeons, Schornagel explains. “You’re not judged by the 100 patients you treat successfully, but by the one patient with a suboptimal outcome. The whole chain is incredibly risk averse as a result.”

Slam Orthopedic therefore hopes to contribute to bone fracture surgery by reducing measuring errors and is convinced it can make a big difference. “Accomplishing our goal would make all those years of hard work worthwhile.”

The past few years have been challenging for Slam Orthopedic, but the company is now rounding the corner, having secured funding for product certification, and is targeting pilots in 2024/2025 at a group of Dutch hospitals that have expressed their interest in the technology. The next step is to enter the European market.

Surgery is a craft and surgeons can do a better job with improved, modern tools and more data. Schornagel therefore hopes that ADEPTH will be deployed in operating theatres worldwide and that the technology's capabilities will be further developed. The team sees plenty of opportunities, for example by equipping drills with interchangeable sensors, tailored to the situation and patient in question. And in the short term? "If all goes well, Bas (de Hartog; ed), who got the ball rolling, will be working with our technology at his hospital later this year."

![[Translate to English:] [Translate to English:]](https://filelist.tudelft.nl/_processed_/b/c/csm_Patient2_blurred_cropped_socials_93e1cd2d9f.png)