ERC-2016-COG | Project no. 725686

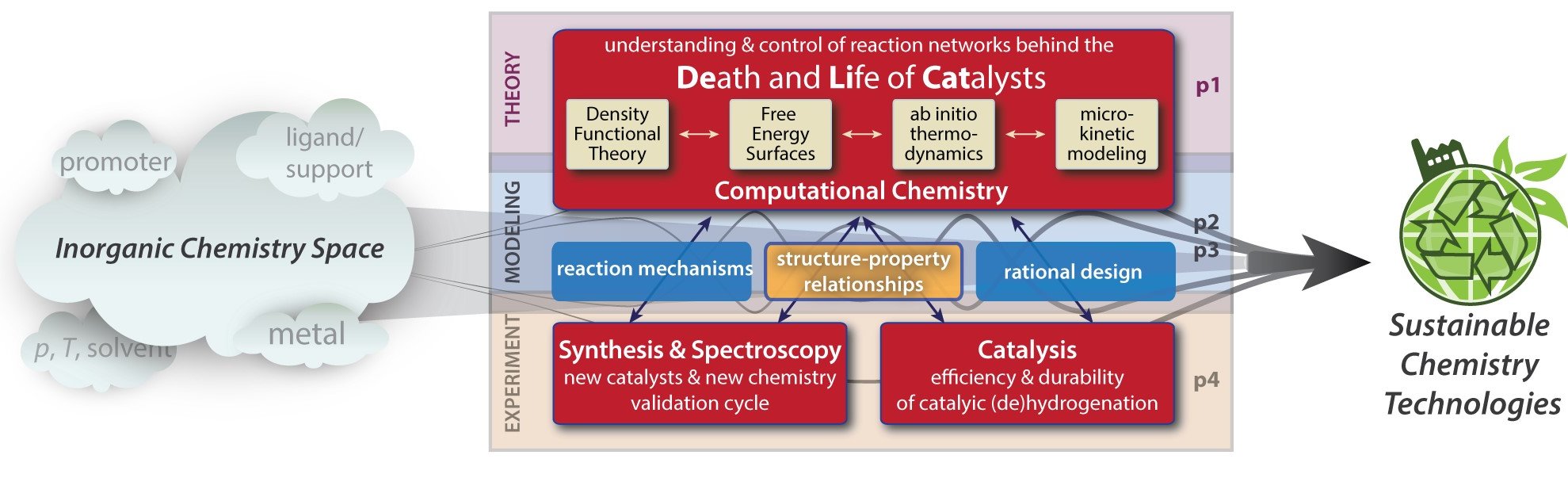

Catalysis plays a pivotal role in all strategies towards sustainable chemical technologies of the future. To minimize the adverse effects due to the use of non-renewable hydrocarbon feedstocks, novel technologies have to be conceived and materialized shortly to enable the direct use of renewable feedstocks and to make the existing chemical processes more atom- and energy-efficient. Endeavors towards the sustainable use of feedstocks should be accompanied by the efforts to make the catalyst utilization also more sustainable. The current paradigm is that most developments in catalysis largely rely on empirical findings gained through laborious experimental efforts, in which potentially active systems can be overlooked simply because of the sub-optimal conditions of the initial activity assessment. Mechanistic and kinetic studies could provide a framework for a more adequate assessment of new catalysts, but such rigorous experiments are not practical for general catalyst discovery. Modern chemical theory and computations hold a promise to be employed in new efficient theory-guided approaches for rational catalyst and process development.

The main aim of DeLiCat is to develop an integrated computational and experimental strategy for the design and optimization of efficient catalytic systems based on non-critical metal-based catalysts for sustainable chemical transformations such as catalytic reduction of carbonyl-containing compounds. Besides their fundamental importance to synthetic organic chemistry as the sustainable alternatives to the conventional stoichiometric routes producing vast amounts of waste, these highly atom-efficient catalytic transformations can be employed in various processes ranging from biomass upgrading to hydrogen storage and fine organic synthesis. In addition, other important catalytic processes such as selective oxidation of methane, dehydrogenation of alkanes, CO2 hydrogenation, electroreduction and other other relevant systems are considered as representative model processes for the integration of computational and experimental catalyst development workflows.

The innovative workflow that we develop in the course of this project integrates advanced chemical theory and computational screening with an experimental chemical and chemical engineering approaches in an efficient knowledge exchange loop. An important goal of the theoretical program in this project is to develop new operando modeling approaches that would allow to better understand how variation in the reaction conditions affects the behaviour of the catalyst system.

These insights would help the experimentalist navigate through the highly complex and multidimensional condition space towards enhanced catalyst lifetime and overall process efficiency.

DeLiCat puts a special emphasis on understanding the undesirable side-reactions resulting in the deactivation of the catalyst and decreasing thus the efficiency of the overall project. Catalyst deactivation is inevitable. However, we propose that by optimizing the catalytic system, one can postpone the deactivation and, hence, improve substantially catalyst performance in terms of the catalyst use so that higher yield of desirable products could be produced with lower catalyst concentration, making the catalyst use more sustainable and contributing to the improved economics of the process. In this project we use computer simulations to understand the chemistry of the “death” and the “life” of catalyst systems and learn how to control the underlying chemical transformations. These insights are then used in the targeted design of novel multifunctional catalyst systems to direct the selectivity of the reaction network and to prevent deactivation paths.

DeLiCAT Publications

-

1. Computational approach to molecular catalysis by 3d transition metals: challenges and opportunities

K. D. Vogiatzis, M. V. Polynski, J. K. Kirkland, J. Townsend, A. Hashemi, C. Liu, E. A. Pidko

Chem. Rev. 2019, 119, 2453

2. Catalytic (de)hydrogenation promoted by non-precious metals - Co, Fe and Mn: recent advances in an emerging field

G.A. Filonenko, R. van Putten, E.J.M. Hensen, E.A. Pidko

Chem. Soc. Rev. 2018, 47, 1459

3. Engineering of transition metal catalysts confined in zeolites

N. Kosinov, C. Liu, E.J.M. Hensen, E.A. Pidko

Chem. Mater. 2018, 30, 3177

4. Towards operando computational modeling in heterogeneous catalysis”

C.J. Heard, L. Grajciar, A.A. Bondarenko, M.V. Polynski, J. Meeprasert, E.A. Pidko, P. Nachtigall

Chem. Soc. Rev. 2018, 47, 8307

-

5. Intrinsic Dynamics and Condition Dependence of Homogeneous Ester Hydrogenation Revealed by Mn‐CNC Pincers

W. Yang, T.Y. Kalavalapalli, A.M. Krieger, T.A. Khvorost, I.Yu. Chernyshov, M. Weber, E.A. Uslamin, E.A. Pidko, G.A. Filonenko

ChemRxiv 2021, DOI: 10.33774/chemrxiv-2021-7k0m3

6. Manganese-mediated C-C bond formation: alkoxycarbonylation of organoboranes

R. van Putten, G.A. Filonenko, A.M. Krieger, M. Lutz, E.A. Pidko

Organometallics 2021, 40, 674

7. Robust and Efficient Hydrogenation of Carbonyl Compounds Catalysed by Mixed Donor Mn(I) Pincer Complexes

W. Yang, I. Yu. Chernyshov, R.K.A. van Schendel, M. Weber, C. Müller, G.A. Filonenko, E.A. Pidko

Nat. Commun. 2021, 12, 12

8. Efficient and practical transfer hydrogenation of ketones catalyzed by a simple bidentate Mn-NHC complex

R. van Putten, J. Benschop, V. J. de Munck, M. Weber, C. Müller, G. A. Filonenko, E.A. Pidko

ChemCatChem 2019, 11, 5232

9. Fuelling the hydrogen economy: Scale-up of an integrated formic acid-to-power system

R. van Putten, T. Wissink, T. Swinkels, E.A. Pidko

Int. J. Hydrog. Energy 2019 , 53 , 28533

-

10. CO2 hydrogenation to methanol over Cd4/TiO2 catalyst: insight into multifunctional interface

G. Li, J. Meeprasert, J. Wang, C. Li, E.A. Pidko

ChemCatChem 2022 , e202101646

11. Highly dispersed Cd cluster supported on TiO2 as an efficient catalyst for CO2 hydrogenation to methanol

J. Wang, J. Meeprasert, Z. Han, H. Wang, Z. Feng, C. Tang, F. Sha, S. Tang, G. Li, E.A. Pidko, C.

Chin. J. Catal. 2022, 43, 761

12. Active Sites in a Heterogeneous Organometallic Catalyst for the Polymerization of Ethylene

D.B. Culver, R.W. Dorn, A.Venkatesh, J. Meeprasert, A.J. Rossini, E.A. Pidko, A.S. Lipton, G.R. Lief, M.P. Conley

ACS Cent. Sci. 2021, 7, 1225

13. Mechanistic investigation of benzene esterification by K2CO3/TiO2: the catalytic role of the multifunctional interface

J. Meeprasert, G. Li, E.A. Pidko

Chem. Commun. 2021, 57, 7890

14. Gold and Silver-Catalyzed Reductive Amination of Aromatic Carboxylic Acids to Benzylic Amines

R. Coeck, J. Meeprasert, G. Li, T. Altantzis, S. Bals, E.A. Pidko, D. De Vos

ACS Catal. 2021, 11, 7672

15. Propane Dehydrogenation on Ga2O3-Based Catalysts: Contrasting Performance with Coordination Environment and Acidity of Surface Sites

P. Castro-Fernández, D. Mance, C. Liu, I.B. Moroz, P.M. Abdala, E.A.Pidko, C. Copéret, A. Fedorov, C.R. Müller

ACS Catal. 2021, 11, 97

16. Mechanistic Complexity of Asymmetric Transfer Hydrogenation with Simple Mn–Diamine Catalysts

R. van Putten, G.A. Filonenko, A. Gonzalez de Castro, C. Liu, M. Weber, C Müller, L. Lefort, E.A. Pidko

Organometallics 2019, 38, 3187

17. Computational insights into the catalytic role of the base promoters in ester hydrogenation with homogeneous non-pincer-based Mn-P,N catalyst

C. Liu, R. van Putten, P.O. Kulayev, G.A. Filonenko, E.A. Pidko

J. Catal. 2018, 363, 136

-

18. ChemSpaX: exploration of chemical space by automated functionalization of molecular scaffold

A. V. Kalikadien, E.A. Pidko,V. Sinha

Digital Discovery 2022, 1, 8

19. Utilizing Design of Experiments Approach to Assess Kinetic Parameters for a Mn Homogeneous Hydrogenation Catalyst

R. van Schendel, W. Yang, E. A. Uslamin, E. A. Pidko

ChemCatChem 2021, 13, 4886

20. The Impact of Computational Uncertainties on the Enantioselectivity Predictions: A Microkinetic Modeling of Ketone Transfer Hydrogenation with a Noyori-type Mn-diamine Catalyst

A. M. Krieger, V. Sinha, A. V. Kalikadien, E. A. Pidko

Z. Anorg. Allg. Chem. 2021, 647,1468

21. Accurate and rapid prediction of pKa of transition metal complexes: semiempirical quantum chemistry with a data-augmented approach

V. Sinha, J.J. Laan, E.A. Pidko

Phys. Chem. Chem. Phys. 2021, 23, 2535

-

22. Solvent-mediated outer-sphere CO2 electro-reduction mechanism over the Ag111 surface

V. Sinha, E. Khramenkova, E.A. Pidko

Chem. Sci. 2022, DOI: 10.1039/D1SC07119J

23. High Stability of Methanol to Aromatic Conversion over Bimetallic Ca,Ga-Modified ZSM-5

C. Liu, E.A. Uslamin, E. Khramenkova, E. Sireci, T.L.J. Ouwehand, S. Ganapathy, F. Kapteijn, E. A. Pidko

ACS Catal. 2022, 12, 3189

24. Unraveling the Nature of Extraframework Catalytic Ensembles in Zeolites: Flexibility and Dynamics of the Copper-Oxo Trimers in Mordenite

E.V. Khramenkova, M.G. Medevedev, G. Li, E.A. Pidko

J. Phys. Chem. Lett. 2021, 12, 10906

25. The Impact of Computational Uncertainties on the Enantioselectivity Predictions: A Microkinetic Modeling of Ketone Transfer Hydrogenation with a Noyori-type Mn-diamine Catalyst

A. M. Krieger, E. A. Pidko

ChemCatChem 2021, 13, 3517

26. Direct Diels–Alder reactions of furfural derivatives with maleimides

R. Cioc, M. Lutz, E.A. Pidko, M. Crockatt, J. K. Van der Waal, P.C.A. Bruijnincx

Green Chem. 2021, 23, 367

27. Composition- and Condition-Dependent Kinetics of Homogeneous Ester Hydrogenation by a Mn-Based Catalyst

A. Krieger, P. Kulyaev, F. Armstrong Hall, D. Sun, E.A. Pidko

J. Phys. Chem. C 2020, 124, 26990

28. Photochromic Free MOF-Based Near-Infrared Optical Switch

N. K. Kulachenkov, D. Sun, Y. A. Mezenov,A.N. Yankin, S. Rzevskiy, V. Dyachuk, A. Nominé, G. Medjahdi, E.A. Pidko, V.A. Milichko

Angew. Chem. Int. Ed. 2020, 59, 15522

29. Operando Modeling of Multicomponent Reactive Solutions in Homogeneous Catalysis: from Non-standard Free Energies to Reaction Network Control

P.O. Kulyaev, E.A. Pidko

ChemCatChem 2020, 12, 795

30. Importance of Methane Chemical Potential for Its Conversion to Methanol on Cu-Exchanged Mordenite

J. Zheng, I. Lee, E. Khramenkova, M. Wang, B. Peng, O. Gutiérrez, J. Fulton, D. Camaioni, R. Khare, A. Jentys, G. Haller, E. Pidko, M. Sanchez-Sanchez, J. Lercher

Chem. Eur. J. 2020, 26, 7563

31. Multicolor Organometallic Mechanophores for Polymer Imaging Driven by Exciplex Level Interactions

G.A. Filonenko, D. Sun, C. Mueller, M. Weber, E.A. Pidko

J. Am. Chem. Soc. 2019, 141, 9687

32. Tracking Local Mechanical Impact in Heterogeneous Polymers with Direct Optical Imaging

G.A. Filonenko, J.A.M. Lugger, C. Liu, E.P.A. van Heeswijk, M.M.R.M. Hendrix, M. Weber, C. Müller, E.J.M. Hensen, R.P. Sijbesma, E.A. Pidko

Angew. Chem. Int. Ed. 2018, 57, 16385