IDE students soaring high with three Crystal Cabin Awards nominations

The 21 finalist of the Crystal Cabin Awards 2023 have been announced. The 21 selected entries offer a fascinating view of the future of flying, from innovative seats to next-generation connectivity technology, from air purifiers to economy class beds – and even a Wi-Fi connected facemask for video calls.

And in a very exciting turn of events, this year, within the University category, student groups from the TU Delft Faculty of Industrial Designing Engineering have claimed all three nomination spots. Each project focuses on the passenger experience in the air, specifically seating.

The Alba Seating Concept is an ultra-light seating fixture inspired by the biological form of the human spine that uses netting as a seat fabric to lower overall mass. A competing team from IDE in cooperation with Embraer submitted Horus, a different approach to low-weight seating designed for use on hydrogen-powered aircraft from 2030 and beyond. The team behind the third entry have designed a 3D printed cushion that optimally supports the human body to provide better seating comfort in a lightweight and sustainable product.

The finalists will have the opportunity to present their concepts in person to the jury at the world's leading trade fair for aircraft cabins, the Aircraft Interiors Expo (6-8 June 2023 in Hamburg). The winners of the Crystal Cabin Award 2023 will be announced on the evening of 6 June at a gala dinner at the Hamburg Chambers of Commerce.

Get to know the projects

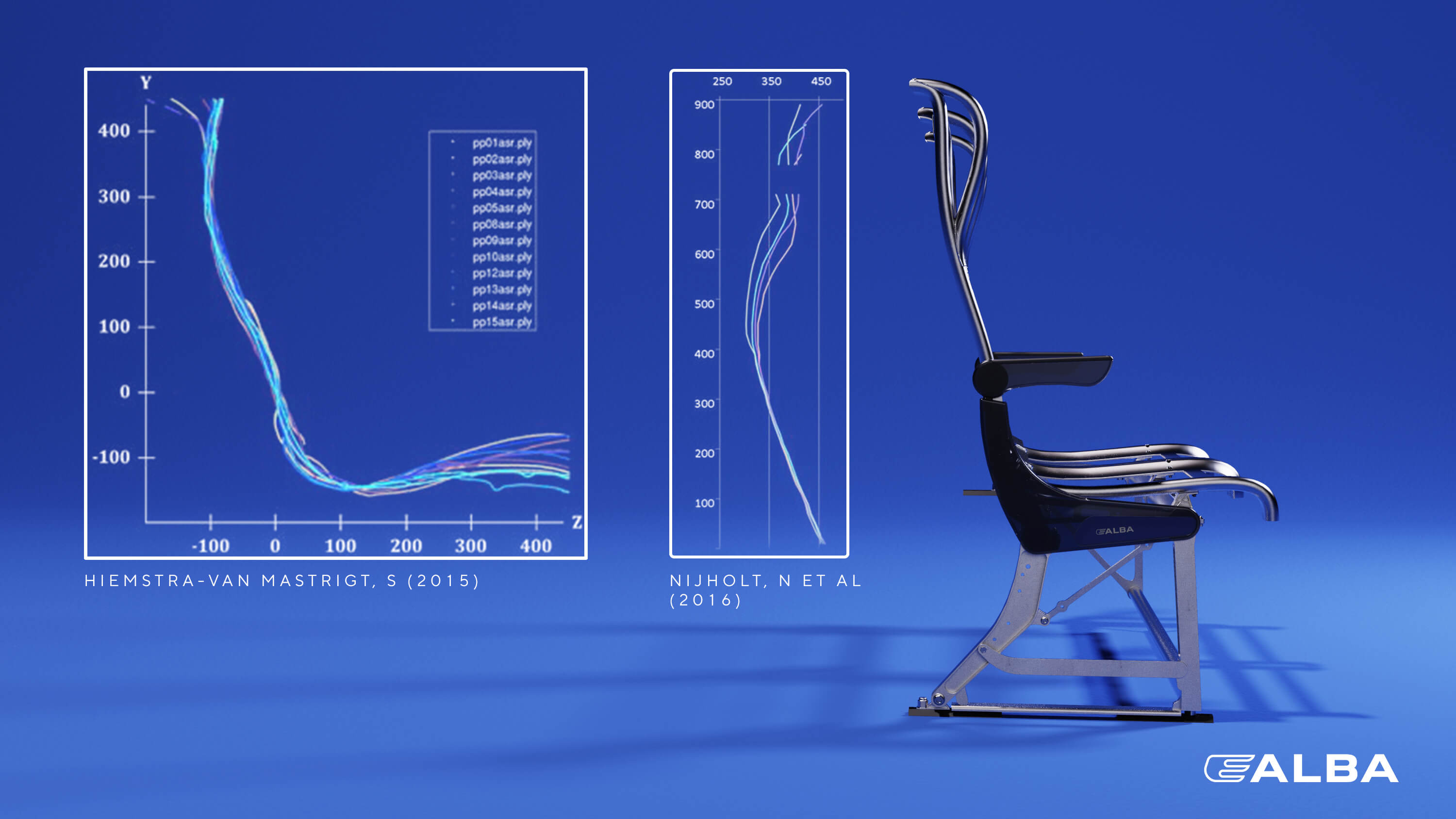

The Alba Seating Concept is the first human contour-based ultra-light aircraft seat for short- and medium-haul flights.

The concept is the first feasible archetype for a fully netted aircraft seating design. By removing non-essential parts and replacing foam with suspension fabric, we can save weight, increase legroom, and improve recyclability without compromising comfort. Half of the weight of an aeroplane seat is non-structural, with foam contributing eminently. While there have been major advances in weight reduction of seats, optimisation of the current design is reaching its limits.

With the guidance of the Delft University of Technology, the Alba Seating Concept was designed as a new statement for comfort and sustainability within the current aviation industry, foreseeing the emergence of short-haul electric flying (e-flight) in the near future. Based on the scientific research of Hiemstra-van Mastrigt (2015) and Nijholt et al. (2016), the human contour was defined.

Team: Floris Priester, Daan den Hollander, Daantje Vogels, Maria Sofia Clercx Lao, Max Nijhuis, Rens Kierkels.

Team Horus, under the guidance of Embraer, made a lightweight, sustainable and comfortable aircraft seat to be fitted within a future hydrogen aircrafts by Embraer (2x2 seater).

They did the project in the AED course of the Integration Product Design master’s programme. The Horus Seat weighs approximately 6,1 Kgs and the weight reduction with comparable comfort estimation to existing seats was made possible by redesign for form & function as well as material innovations.

Form innovations included: A prominent lumbar support curve using extensive ergonomic study (3d scanning, pressure mapping & curve extraction). The lumbar support is used to make a metal composite frame and a 3d spacer fabric dual netted backrest. Seats that have sleek armrests and compact devices & cup holder sin the backrest (all of which is in line with the requirements of short haul flight passengers). Sustainable, lightweight (30% lighter) seat cushions conforming to the shape of users (recommendation) and topology Optimized Overhead bins.

Team: Arabella Van Lookeren, Jayneel Soni, Reina Swinkels, Yujing Cai, Mrinal Chaudhury.

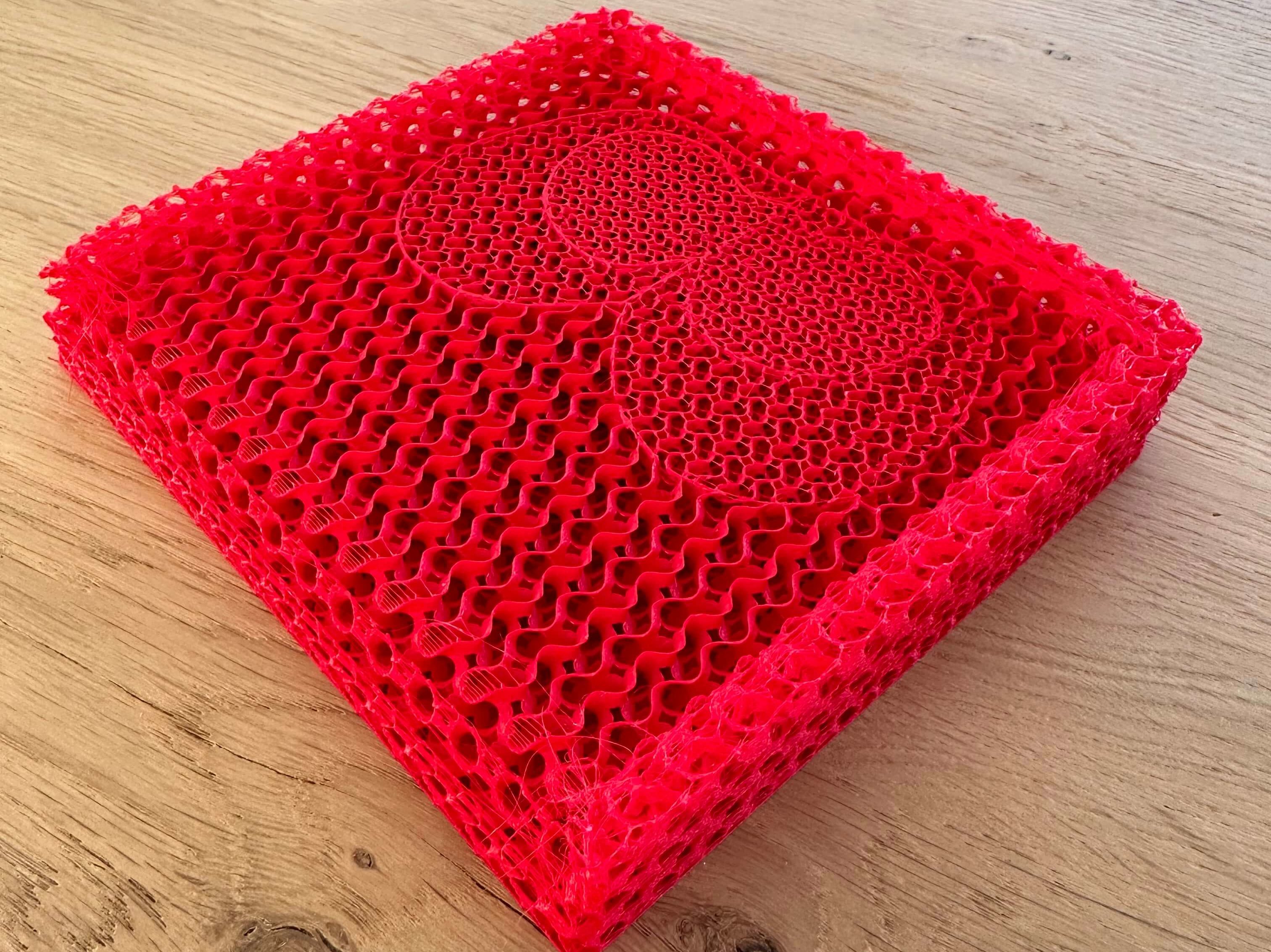

Team Lightweight Aircraft Seating designed a lightweight, sustainable, and comfortable 3D printed cushion with a cactus leather upholstery.

The concept is lightweight, comfortable and sustainable. Lightweight because, the cushions of the seat are made of flexible thermoplastic elastomer TPU-98A via Fused Deposition Modelling (FDM); a specific 3D printing technique.

Via this technique ‘shape memory’ can be implemented, the shape returns to its original form after deflection. By using different infill percentages of a gyroid structure in the seating, different parts of the body can be supported. While at the same time, ensuring that no extra weight is used, only what is necessary.

The top layer of the chair is made of cactus leather, this is leather made of cacti and can be harvested without killing them and in half a year a new skin is produced. It is highly durable and gives users an expensive feel. Next to this, it also grows in Brazil, close to the Embraer plant.

Team: Thomas Hogeveen, Bas Ammerlaan, Maartje Ballemans en Agi Strijker

Crystal Cabin Awards

The Crystal Cabin Award is the international prize for innovation in the aircraft cabin. A high-calibre jury made up of renowned academics, engineers, specialist journalists and airline and aircraft manufacturer representatives comes together under the slogan “Let your ideas take off” to honour extraordinary cabin concepts and products. The competition was launched by Hamburg Aviation and is organised by the Crystal Cabin Award Association. This unique honour has been presented at the Aircraft Interiors Expo in Hamburg every year since 2007. The trophies have become a seal of quality, known and coveted around the world.