The LETT

At the TU Delft there are not enough (easy to operate) tensile testers for students to be able to perform tensile tests. These tensile testers are commercially available, however these are very expensive. The result is that most students, after only a couple of years, no longer remember anything about material testing, let alone remember how to calculate material characteristics like the Young’s modulus or the yield strength.

Goals of the project

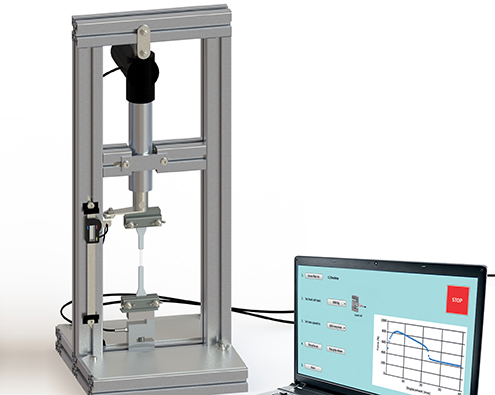

To design a desktop tensile tester that can test plastic material specimens of up to 4 mm thick, with a working area of 200 mm and a force of up to 3 KN for less than €1000,- (material & shipping costs).

The design

The focus of this design is on cheap and simple and not on accuracy. The LETT features a linear actuator hung upside down in a frame, eliminating complicated and expensive transmissions. Two load cells (rated up to 500 Kg and 100 Kg) result in a measuring range of 10 to 400 Kg. The load cells are easily replaced and the extra load cell is stored in an easy to access compartment in the base of the LETT.

The LETT is controlled via a user interface on the computer which controls, among other things, the speeds of testing and which plots the results of a test in a graph. In the user interface the user can indicate where the LETT should store a text file with the results of each test. The LETT can be manufactured for less than €500,- (material & shipping costs).

More information

Kaspar Jansen

- +31 (0) 152786905

- k.m.b.jansen@tudelft.nl

-

Room B-3-170

Researchers

- Prof. K.M.B. Jansen

- Ing. M. Verwaal

Graduate student

- Pieter Welling