SHAREPAIR

How do we stimulate people to repair their devices, instead of throwing them away? How can we make repair easier and more attractive? In the European Interreg project SHAREPAIR, design researchers from TU Delft work together with neighborhood repair cafés to find answers to these questions, especially investigating how 3D printing can facilitate repair.

This project aims to decrease waste from consumer products by scaling up citizen repair initiatives through the use of digital tools. These tools collect repair solutions and make them easily accessible to everyday people. They will target both ordinary people at home and skilled repairers in repair cafés.

The role of TU Delft’s Sustainable Design Engineering team is primarily to enable 3D printing for repair. First, we identify current opportunities and obstacles, then we develop digital tools and training to assist ordinary people in using 3D printing to repair their broken household products. This will include an open-source database of 3D part designs for printing replacement parts, as well as tutorials for people to learn the skills needed. It will include how to 3D model replacement parts, print them, determine quality, and perhaps redesign replacement parts to upgrade their products or compensate for the lower mechanical performance of 3D printing materials compared to the product’s original materials.

The objective is to decrease Waste Electronical and Electronic Equipment (WEEE) by 10% in pilot repair cafés, for a total of 15 tonnes of waste avoided per year. Additionally, SHAREPAIR aims to avoid 0.5 tonnes of WEEE per 1,000 inhabitants in the pilot cities. Ultimately, this would result in a total of 100 tonnes of waste avoided per year.

Jeremy Faludi is an expert on 3D printing for sustainability and Bas Flipsen loves to fix stuff.

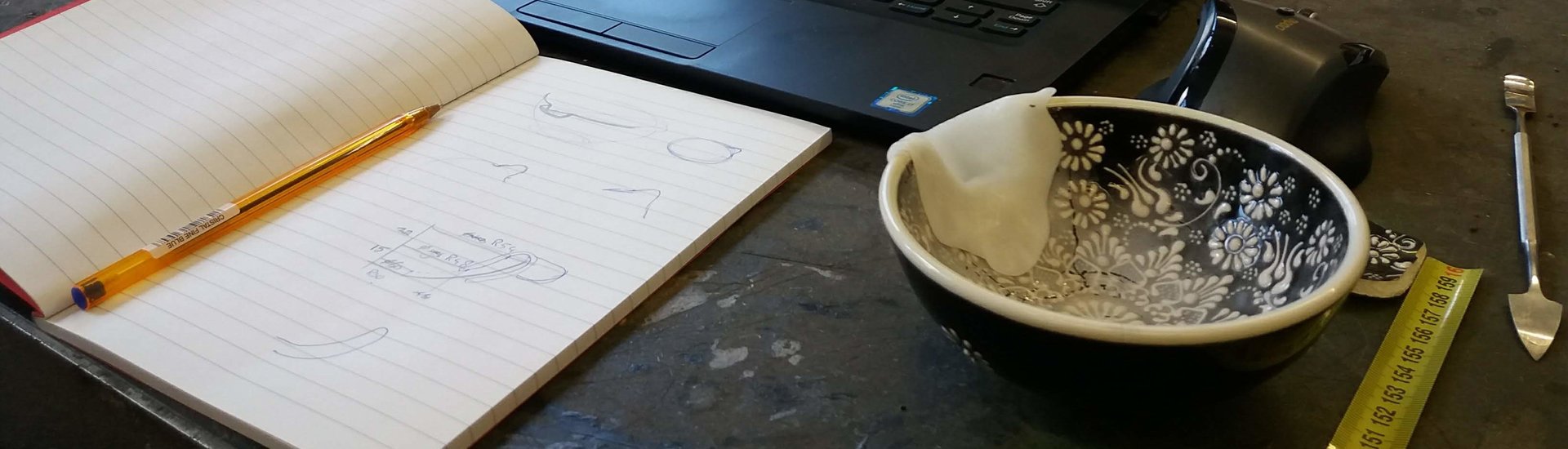

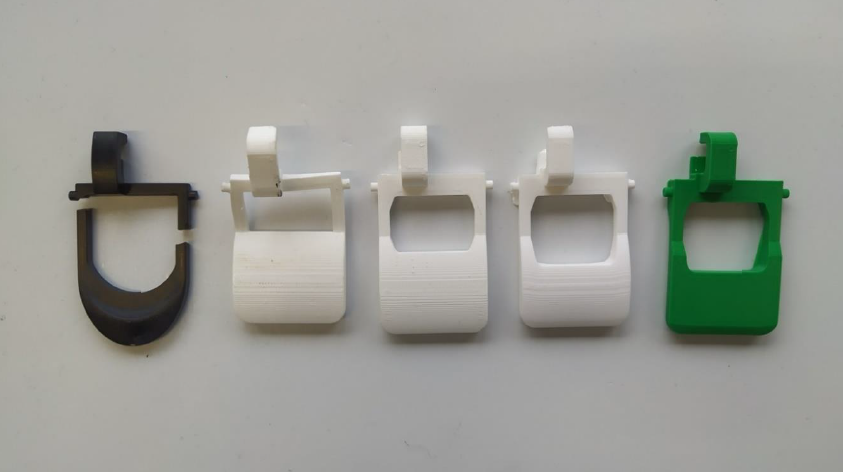

The broken switch from a kettle was replaced with a 3D printed PLA bioplastic version. Because of the different materials and manufacturing, the switch had to be reverse-engineered with a slightly different shape. That required testing and design iterations.

3D printing for repair can not only make products as good as new, but better than new, by adding personalization or new functionality.

Several Instructables on details of 3DP4R, including handling snap fits, simplifying part geometry, partial repair with controlled destruction, parametric adapters, and universal parts. Also, two Instructables on the overall 3DP4R process that’re precursors to the guide above.

Bas Flipsen

- +31 (0)15 27 89398

- s.f.j.flipsen@tudelft.nl

-

Room 32-B-3-090

Present on: Mon-Tue-Thu-Fri

"Leave tracks, no traces."

Jeremy Faludi

- +31 (0)15 278 98 07

- J.Faludi@tudelft.nl

- faludidesign.com

-

Room 32-B-3-320

Present on: Mon-Tue-Wed-Thu-Fri

"To get the future you want, start building now."