LICHEN-BLADES

While they contribute to the growth of renewable energy, wind turbines also contribute to landfill waste and emissions upon decommissioning. The blades of these turbines are especially difficult to recycle because they are made from composite materials. With an average life span of 25 years and the continuous growth of wind energy, it is estimated that 325,000 tonnes of wind turbine blade waste will be produced annually in Europe until 2050. This unsustainable material sourcing and waste problem needs to be tackled with transdisciplinary strategies that take the end-of-life of the blades into consideration from the design stages.

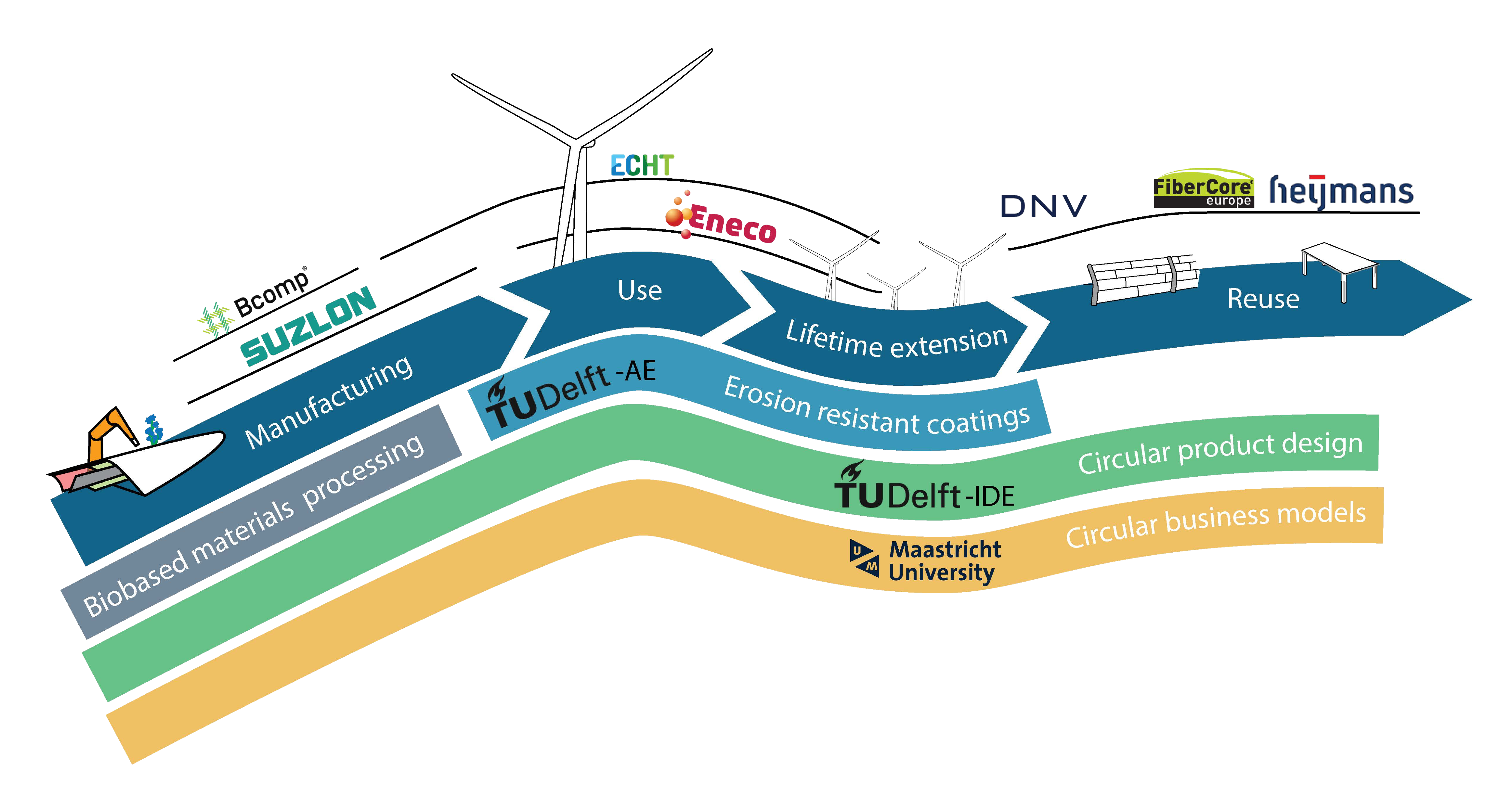

The design methods and strategies implemented within this project require a deep understanding of the entire product life-cycle, which is highly complex and involves the intersection of material knowledge, business model development, and supply chain understanding. The IDE team will consider different bio-based materials, while also ensuring implementation by industry through new business models and value chains.

How will the project tackle research questions?

Within this project, the IDE team will work towards designing blades that last longer and contain more parts that can be recovered and used in high-quality applications over multiple life-cycles. This project builds on Jelle Joustra’s PhD work, in which he used a research by design approach to investigate how current wind turbines could be repurposed and shed light on the physical and material considerations for future blade designs.

Expected results

Expected outcomes include a circular blade design that will enable re-use. The IDE team proposes a circular blade design that will realize the functionality of the first use-cycle and successive use-cycles, enabling blades with a reduced carbon footprint, and designed for re-use opportunities. The blade will be made of carbon capturing materials with minimum waste from manufacturing. New coating materials will reduce erosion, thereby extending lifetime. At the end of service life, the blades will be re-used as high-value components in the construction industry. To understand viable routes to market, new business models for the circular economy will be explored, aiming to keep materials at the highest value as long as possible while distributing value over all stakeholders.

Ruud Balkenende

- +31 15 27 81658

- a.r.balkenende@tudelft.nl

-

Room B-3-310

Jelle Joustra

- +31 (0)15 27 89048

- j.j.joustra@tudelft.nl

- Personal website

-

Room 32-B-3-290

Present on: Mon-Tue-Wed-Thu-Fri