Em. Prof. dr. ir. Geraedts, J.M.P.

Emeritus Professor of New Mechatronic Design (2019)

Department Design Engineering, section Mechatronics Design

Biography

Prof. Jo Geraedts joined Océ-van der Grinten N.V. in 1983 and retired from Océ, a Canon group on 1 September 2017. The challenge for Océ is designing products and systems that are very productive and reliable in a complex document management workflow. Therefore ease of use and ergonomics are decisive product qualities.

In R&D he was responsible for the quality and reliability of the scanning, imaging and printing process and user interface of the first Océ Multifunctional Digital Copier for the Office: the Océ 3165. In 1995 he became senior scientist.

From 1996 till 2003 Prof. Jo Geraedts was manager of Group Research department and responsible for a healthy and sound research program to develop technology and application options for adaptability of Océ to the changing world of printing. In this period he started the first research projects for mechatronic solutions.

From 2000 till 2013 he was manager of the Océ Industrial Design department. Step by step Prof. Jo Geraedts became on corporate level responsible for the strategy and day-to-day management of product-, graphic- and user interaction design of Océ hardware and software products. In 2010 Océ became part of the Canon Group and his department had to be coordinated with Canon Design in Tokyo.

Furthermore Océ Design has won many (inter-) national design awards in GIO (the Netherlands), iF (Germany, China), Red Dot (Germany), IDSA (United States of America) and Good Design (Japan).

Prof. Jo Geraedts was appointed chair of new mechatronics design in 2008 at TU Delft and build step for step a new research environment into 3D multi-modal scanning, 3D multi-material printing and human–robot interaction.

Also see his LinkedIn page

Education

- 1983

Ph.D., Physics, Radboud University of Nijmegen

Infrared laser development, intermolecular physics, spectroscopy of clusters - 1976

M.A., Physics, Technical University of Eindhoven

Laser development, optics, gas dynamics

Experience

- New (mechatronic and software) product design and technology/product road mapping;

- User centered design of complex systems/products with different stakeholders within multidisciplinary (international) teams.

- Eco design, Sustainability and Cradle to Cradle thinking for new product development;

- System/product validation and specification/reliability testing;

- 3D-Scanning and 3D-printing process development.

Specialisation / field of research

Products around us are increasingly digitized, autonomous and connected. The increasing digitization and complexity of society is transforming how we perceive, use, and are affected by technology. The technology nestles in people and among people, has knowledge about people, and can more and more act as part of people bringing increasing computational power and new solutions for digital design, simulation, and digital manufacturing.

Mechatronics enables us to build better products with optimal behaviour in terms of its learning ability, usability, and reliability. Today we can use adaptive control in real time to optimize the (operator) productivity, and reduce the variations in the environment or in the system itself. The range of controlling is from (global) systems of distributed (wireless) sensor networks to real-time sensor-actuator implementations in physical products.

Mechatronics allows designers to optimize a product’s behaviour in terms of its learning ability (smart, adaptive, intelligent), usability (convenient), and reliability (trust, robust). However, with the advent of digital design and manufacturing, the designer’s means to address this are changing. Therefore, the development of new approaches for Mechatronics is needed. Designers are instrumental in shaping these developments.

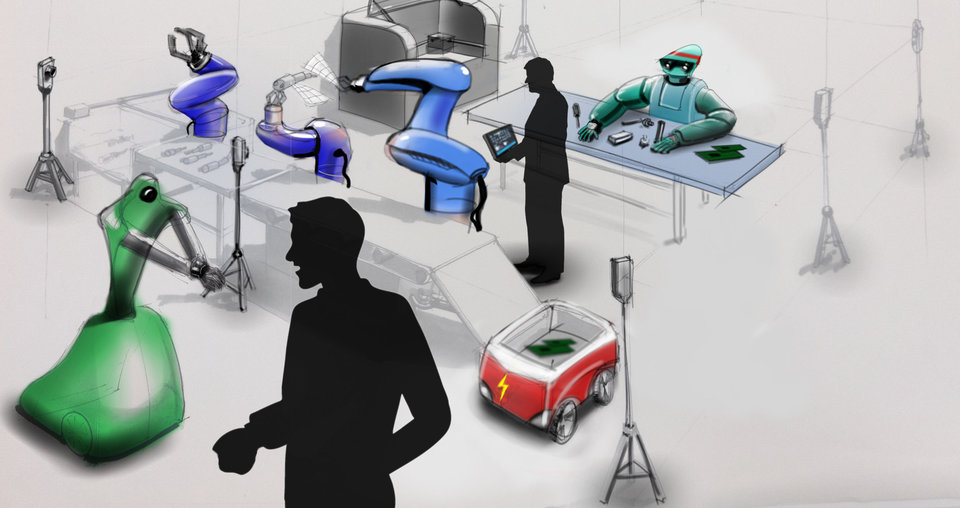

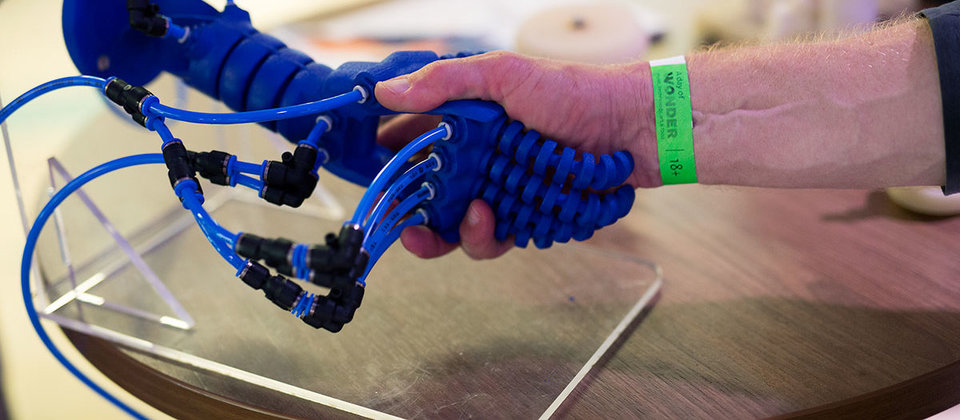

Facilitated by the user centred design method, our approach bridges the gap between technology, the needs of the users and the market. Key research areas include the use of robotics, 4D scanning, 4D image processing and 4D printing technologies with the integration of embedded 3D printed electronics, sensors and actuators.

Applications include products, but also new (multi material) structures with designed mechanical properties, mechatronic principles (smart mechanics), and material experiences (visual perception, haptics).

Robots are a specific application of mechatronics and our research is focused on industrial co-production of human operators and robots. Digital manufacturing provides the ability for the physical product and its digital counterpart to coincide and enrich each other (so called digital twin).

Lectures and/or coaches students on:

- Bachelors program: Mechatronics

- Master program: Digital Materials

- Graduation projects about smart products

- Prototyping

- New Product development

- History of technology development

Involved in the research project(s):

Jo Geraedts

"Things should be made as simple as possible, but not any simpler.” - Albert Einstein