Advanced Prototyping minor translates ideas into tangible designs

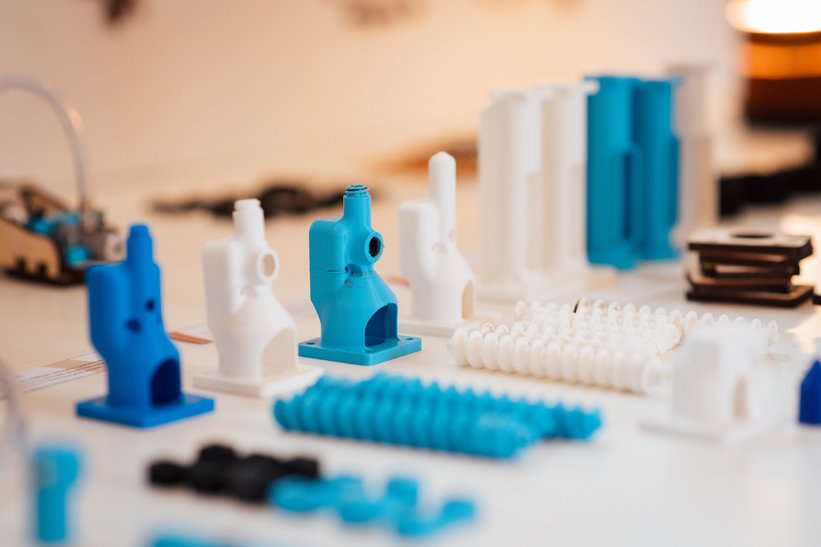

While we have certainly learned just how much can be achieved virtually, the ability to translate an idea into a tangible prototype remains an important design competency. Thus, we were happy to hear that the students from the Advanced Prototyping minor were able to host a small exhibit to display their projects last Thursday. This year’s projects focused on digital fabrication and/or smart textiles and the results were quite impressive. In total, there were seven group projects.

Over the course of the last semester students of the Advanced Prototyping minor have been hard at work, designing, developing, validating and finessing their prototypes, employing new advanced manufacturing techniques and emerging material applications.

Willemijn Elkhuizen, one of the minor’s course coordinators, notes: “It was great to see and interact with the many prototypes the students made and have them explain how they were created and tested. The students of the minor really excelled again this year, especially considering all the limiting factors, of yet another COVID year. Many thanks to the students for all their hard work, the coaches and clients, and especially the TU Delft Science Centre for once again hosting us.”

About the projects

The students of Designed4Repair developed four distinct design strategies for repairing consumer household electronics, which they applied to vacuum cleaners, and created accompanying instructions. This project was in collaboration with the client ShaRepair.

The students of CeramicXL developed three concepts for fabricating (more) affordable architectural façade elements using large-scale ceramic 3D printing. This project was in collaboration with the client Studio RAP.

The students of Paste is the Future explored paste extrusion 3D printing to develop new, sustainable printing materials, which use no energy for heating the print filament, and can be reprinted or completely biodegraded at end-of-life. This project was in collaboration with the client and IDE Assistant Professor Jeremy Faludi.

The students of VarioSeat developed an ultra-personalised office seating concept by incorporating sitting pressure measurements, generating a custom design, and 3D printing compliant, cushioning elements. This project was in collaboration with the client Ahrend.

The students of Rethinking Replex conceptualised a new, urban application for a biodegradable sheet material, which is made from water treatment plant waste and is subsequently processed using digital fabrication technologies. This project was in collaboration with the client AMS Institute.

The students of Lattice Structures go Large Scale designed and explored new applications for lattice structures, which can be digitally fabricated and easily assembled and reconfigured. This project was in relation to the research of IDE Assistant Professor Jun Wu.

The students of Wearing an Instrument created a modular smart-textile concept, allowing for an easy introduction to music making using textile-based sensors. This project was in collaboration with the Smart Textiles Group, which includes IDE Professor Kaspar Jansen and IDE researcher Marie Chae.

The minor

The Advanced Prototyping Minor is a programme that brings together the most recent research topics related to advanced manufacturing (digitalisation, design automation and digital fabrication) and emerging materials, to create functional low and high-fidelity prototypes. The course aims at equipping students with a wide range of advanced prototyping skills and in-depth knowledge of current state-of-the-art techniques to create prototypes which capture both function and appearance of the intended design. Find out more on the dedicated website.

Special thanks

A big thank you goes out to the minor’s coaches (Willemijn Elkhuizen, Sander Minnoye, Eliza Noordhoek, Mika de Bruijn, Steven Polak, and Freerk Wilbers), the companies and colleagues who served as clients (Ahrend, Studio RAP, AMS Institute, the EU ShaRepair project (Bas Flipsen, Alma van Oudheusden, Julieta Bolanos Arriola), the Smart Textiles Group (Kaspar Jansen and Marie Chae), Jeremy Faludi, and Jun Wu), as well as all the students who worked so hard to create such great results!

Willemijn Elkhuizen

- +31 15 27 81041

- w.s.elkhuizen@tudelft.nl

-

Room 32-B-3-220

"One must work and dare if one really wants to live."