Long queues at Schiphol Airport, delayed healthcare, restaurants that are open less often. We are seeing staff shortages more and more frequently. The workload in physical jobs in particular is very high. In these cases, people look to robots for fast solutions, but in practice it is not that easy. Many smart robots remain unused, gathering dust on the shop floor. Prof. David Abbink hopes to radically change the way robots are developed.

“Jobs in healthcare, cleaning, production and logistics often come paired with poor working conditions and low status, while they are essential in our society,” says David Abbink. “To address the personnel shortage, a change is needed at systems level: a revaluation of craftsmen that will make the shop floor attractive again. Robots can help if we technicians dare go into the social, unpredictable and hard to solve problems of work in greater depth.”

Lifting robot that is not used

One example. “I have often worked in multidisciplinary teams and robot support. We once made a really good lifting robot for healthcare workers. After a while we returned to have a chat with the healthcare workers. We heard that the robot was too big and heavy for them and they did not use it. I said to myself that I had done my best and that if they wanted a lifting robot, this is what they will get.” In Abbink’s experience this is a common attitude among robot makers. “We do not really think about how it will be used.”

"Donations from alumni will enable us to test in practice. We will be at the forefront of people who have themselves experienced how robots can become a catalyst for change, not at job level, but for society as a whole."

Prof. David Abbink, professor of Haptic Human-Robot Interaction

New approach

Abbink believes that robots can go a long way in helping make physical jobs more attractive. But this does call for a completely different approach to development. “Firstly, by letting go of the illusion that robots can completely replace workers or take over entire jobs, and instead work on robots that will help make the work easier or better. Secondly, by working transdisciplinary, by starting the development process from the bottom up by asking questions to and collecting the experiences of the people on the shop floor, and by involving other scientific disciplines such as design and social sciences. And finally, by getting involved in the societal debate about revaluing craftsmanship and essential professions.”

Now to put into practice

Abbink and his team hope that donations from alumni will enable them to test this way of working in practice. An interdisciplinary team will start with a need that comes directly from the shop floor. For a brief period they will work closely with each other and with the direct beneficiaries on a solution. This new methodology will help them gather important experiences and set an example for a large-scale follow up. “By doing this, we will be at the forefront of people who think differently. They will be scientists and developers who have themselves experienced how robots can become a catalyst for change, not at job level, but for society as a whole.”

Watch the interview with David

Will you join us?

With a gift, you help accelerate research, enable a pilot, or give students the chance to turn ambitious ideas into reality.

Which Tech for Impact 2023 project can count on your support?

-

Delft University Fund uses your data to process and record your donation and to inform you about the activities and work of the University Fund. Your personal details will be treated confidentially in accordance with the Dutch Personal Data Protection Act and will never be provided to third parties. Please read our privacy statement here

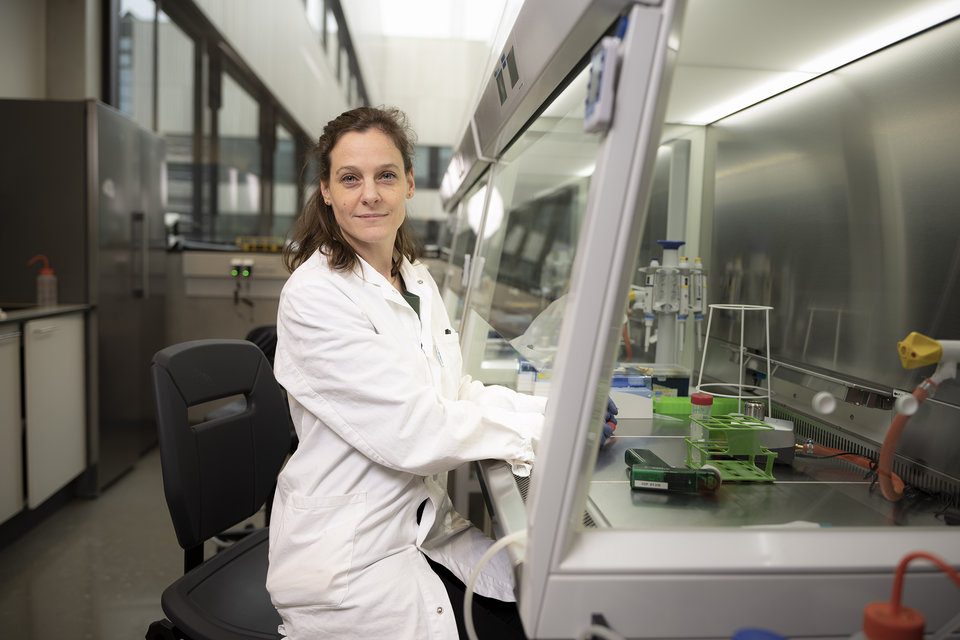

Researcher profile

Name: David Abbink (45)

Born in: Purmerend

Expertise: Professor of Haptic Human-Robot Interaction

Faculty: Faculty of Mechanical Engineering (ME)

Working on: a radical new way to design robots for the shop floor

Impact: making crucial jobs in sectors such as healthcare and logistics more attractive

Donation spent on: starting a practical pilot to test this new way of working

Why TU Delft

“TU Delft can take the lead here. We are used to thinking big and often have one foot in the technology and the other in society. We are best placed to show that things can be and must be done differently. Not through top-down design from a distance, but through thinking bottom-up from the start, assessing the needs, and then finding a solution. This will allow us to design robots that help make essential jobs more attractive rather than continue filling the robot graveyard.”